Information injection-pump assembly

BOSCH

9 400 619 766

9400619766

ZEXEL

106671-2594

1066712594

MITSUBISHI-HEAV

3626510140

3626510140

Rating:

Service parts 106671-2594 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-2594

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 766

9400619766

ZEXEL

106671-2594

1066712594

MITSUBISHI-HEAV

3626510140

3626510140

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

133424-0221

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

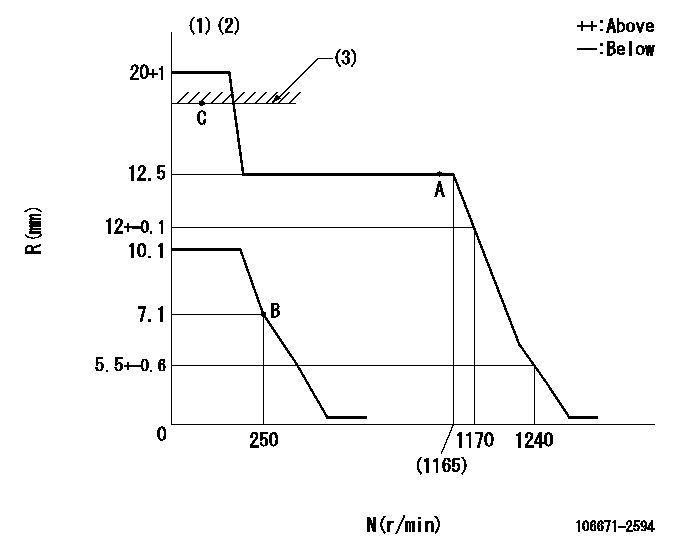

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

282

275

289

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

30

27

33

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

240

240

250

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.9

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_04

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

4

2.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

K=17

----------

----------

K=17

----------

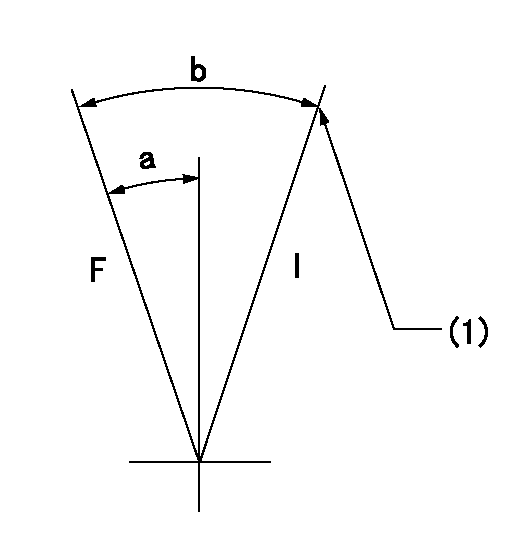

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(20deg)+-5deg b=(38deg)+-5deg

----------

----------

a=(20deg)+-5deg b=(38deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Information:

Typical Example1. Loosen two bolts (2) and two nuts (3). Remove bolt (1), and remove fan drive belts (4).

Typical Example2. Remove the nuts and bolts that hold the fan drive in place. Remove fan drive (5). The following steps are for installation of the fan drive.3. Put fan drive (5) in position on the timing gear cover.4. Install bolts (2) and nuts (3) loosely. Make a replacement of the belts as a set only.5. Install fan belts (4). Install bolt (1). Make an adjustment to the belt tension with tool (A). Measure the belt farthest away from the engine. Tighten new belts to a gauge indication of 120 5. After the engine is operated at high idle for a minimum of 30 minutes, make another adjustment to the belt tension. The correct tension for used belts is a gauge indication of 90 10.6. Tighten bolts (2) and nuts (3) that hold the fan drive in place.Disassemble Fan Drive

Start By:a. remove fan drive 1. Remove two bolts (2) that hold the fan adapter to the pulley.2. Remove fan adapter (1) from the pulley 3. Remove bolts (3) and washer (4). Remove seal (5). 4. Remove pulley (8) from bracket (6).5. Remove bearing (10) and spacer (9) from the pulley. Remove spacer (7), seal (11) and bearing (12) from the pulley.Assemble Fan Drive

1. Install bearing (12) in the rear of pulley (8). 2. Install lip-type seal (11) with tooling (A). The lip of the seal must be away from the bearing. Put 5P960 Multipurpose Type Grease on the lip of the seal.3. Install spacer (7) so the end with the taper is toward the inside of pulley (8).4. Install spacer (9) and bearing (4) in the front of the pulley. 5. Put seal (5) on the front of the pulley. Install the pulley on bracket (6). 6. Install washer (4) and bolts (3) that hold the pulley in position.7. Install the fan drive adapter on the pulley.8. Fill the fan drive with 5P960 Multipurpose Type Grease.End By:a. install fan drive