Information injection-pump assembly

BOSCH

F 019 Z10 026

f019z10026

ZEXEL

106671-2020

1066712020

MITSUBISHI

3096198021

3096198021

Rating:

Service parts 106671-2020 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

30961-99090

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-2020

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 026

f019z10026

ZEXEL

106671-2020

1066712020

MITSUBISHI

3096198021

3096198021

Zexel num

Bosch num

Firm num

Name

106671-2020

F 019 Z10 026

3096198021 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D20MT * K

6D20MT * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105100-4140

Nozzle

105015-3710

Nozzle holder

105031-3520

Opening pressure

MPa

21.6

Opening pressure

kgf/cm2

220

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-700

Outer diameter - inner diameter - length (mm) mm 6-2-700

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

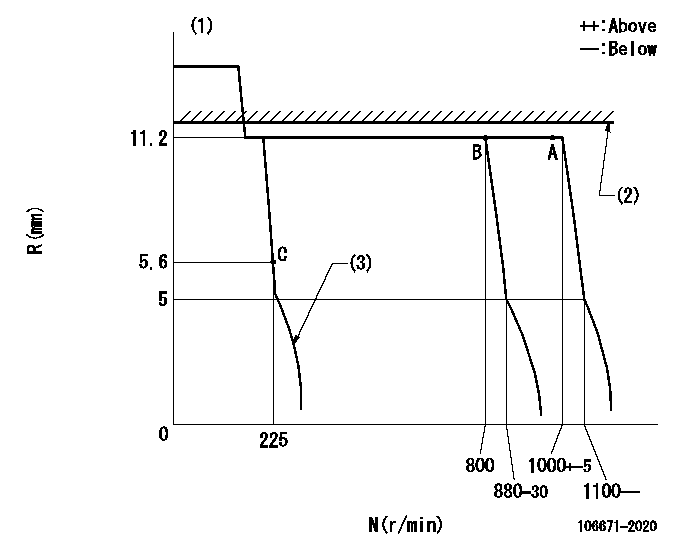

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

980

980

980

Average injection quantity

mm3/st.

158

153.5

162.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.2

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

157.5

154.5

160.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

17.5

14.9

20.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750+100

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Idle sub spring setting: L1.

----------

K=18 RAL=12+0.2mm L1=5-0.5mm

----------

----------

K=18 RAL=12+0.2mm L1=5-0.5mm

----------

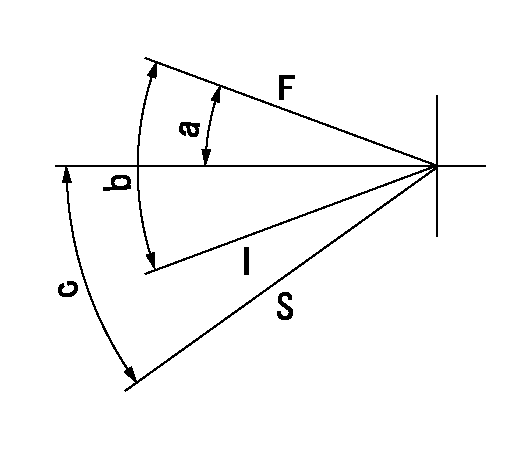

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=13deg+-5deg b=28deg+-5deg c=32deg+-3deg

----------

----------

a=13deg+-5deg b=28deg+-5deg c=32deg+-3deg

Information:

Low power and engine response complaints can be caused by very different reasons and require different repairs, but are often the same complaint from the operator. A discussion with the operator is needed to help correctly diagnose whether to repair for low power or slow response. At times, full engine horsepower is available, but the operator still complains of low power. Repairs for low power would not provide a satisfactory result, and may consume many hours with expensive repairs. The actual complaint may be the engines ability to respond to a changing load or shifting gears.Normally, engine power can be measured to determine if it is within specifications. When troubleshooting a "low horsepower" complaint, if fuel consumption, timing, speeds, and manifold pressure are within specification, do not spend additional time looking for "low engine horsepower". If it is still believed that performance of the vehicle is below that expected, look for horsepower losses in the transmission, differential, clutches, parasitic loads (fan, air compressor, air conditioner, etc.), tires, low fuel density or high temperatures, but not the engine.Owner/Operator Input

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. There Are No Hard And Fast Answers For These Questions. There are many different truck engine specifications and truck vehicle specifications which will provide acceptable results. There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly. 1. Is there a particular operating condition when the complaint occurs?Low power and response complaints require different repairs. Complaints during shifting will be different from complaints of low power in certain speed ranges or in certain terrains. 2. What are the customer's expectations for fuel mileage and power and why does he have those expectations?Comparisons to other trucks on the road often have many unseen variables. If comparison to others is the basis for the complaint, you must insure that the comparison is valid. 3. What are the normal upshift and downshift rpm's?If the shift points are too high, find out why. If the driver is operating this way out of habit or because he is taught to drive that way, arrange for him to receive the Caterpillar driver training information. If his shift points are too high because of poor performance, you may be able to correct this in the engine. 4. What are the normal routes and loads for the truck?You should be looking for the amount of city versus highway driving, versus mountainous, heavy versus light loads, and cold climate versus warm climate. 5. Can the operator detect a misfire?This can lead you to a diagnosis of just one cylinder rather than an entire engine system. 6. Does the engine smoke excessively, and if so, under what conditions?Excessive smoke can give indications about engine settings and engine internal conditions.

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. There Are No Hard And Fast Answers For These Questions. There are many different truck engine specifications and truck vehicle specifications which will provide acceptable results. There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly. 1. Is there a particular operating condition when the complaint occurs?Low power and response complaints require different repairs. Complaints during shifting will be different from complaints of low power in certain speed ranges or in certain terrains. 2. What are the customer's expectations for fuel mileage and power and why does he have those expectations?Comparisons to other trucks on the road often have many unseen variables. If comparison to others is the basis for the complaint, you must insure that the comparison is valid. 3. What are the normal upshift and downshift rpm's?If the shift points are too high, find out why. If the driver is operating this way out of habit or because he is taught to drive that way, arrange for him to receive the Caterpillar driver training information. If his shift points are too high because of poor performance, you may be able to correct this in the engine. 4. What are the normal routes and loads for the truck?You should be looking for the amount of city versus highway driving, versus mountainous, heavy versus light loads, and cold climate versus warm climate. 5. Can the operator detect a misfire?This can lead you to a diagnosis of just one cylinder rather than an entire engine system. 6. Does the engine smoke excessively, and if so, under what conditions?Excessive smoke can give indications about engine settings and engine internal conditions.

Have questions with 106671-2020?

Group cross 106671-2020 ZEXEL

Mitsubishi-Heav

Mitsubishi

106671-2020

F 019 Z10 026

3096198021

INJECTION-PUMP ASSEMBLY

6D20MT

6D20MT