Information injection-pump assembly

ZEXEL

106671-1941

1066711941

ISUZU

1156029490

1156029490

Rating:

Cross reference number

ZEXEL

106671-1941

1066711941

ISUZU

1156029490

1156029490

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.8

3.77

3.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

192

190

194

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

32.7

32.7

Boost pressure

mmHg

245

245

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

230

230

230

Average injection quantity

mm3/st.

12.5

9.3

15.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

11

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

183.5

177.5

189.5

Fixing the lever

*

Boost pressure

kPa

32.7

32.7

Boost pressure

mmHg

245

245

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

9.2

Boost pressure

kPa

6.7

6.7

8

Boost pressure

mmHg

50

50

60

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

11.5

Boost pressure

kPa

19.3

12.6

26

Boost pressure

mmHg

145

95

195

Timer adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

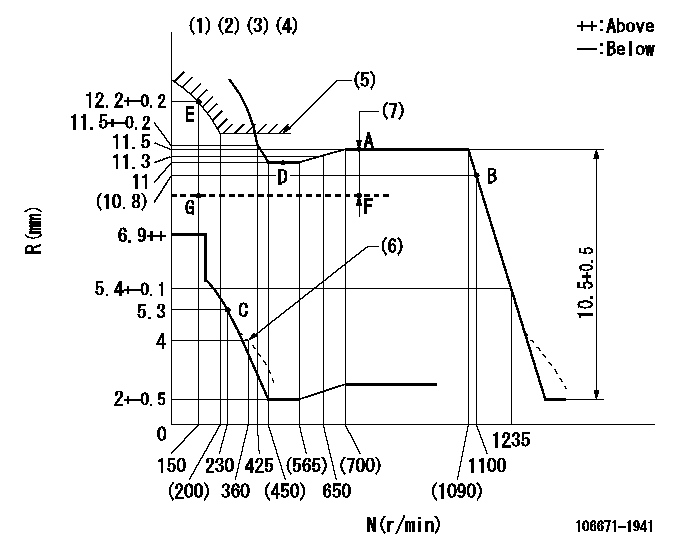

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Supplied with torque spring not set.

(5)Excess fuel setting for starting: SXL (N = N1)

(6)Damper spring setting

(7)Boost compensator stroke: BCL

----------

RT=1 TH=2.6mm SXL=11.8+0.2mm N1=350r/min BCL=2.3+-0.1mm

----------

----------

RT=1 TH=2.6mm SXL=11.8+0.2mm N1=350r/min BCL=2.3+-0.1mm

----------

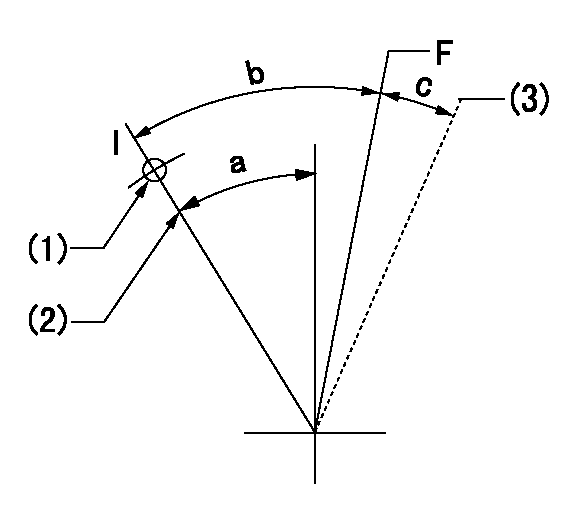

Speed control lever angle

F:Full speed

----------

----------

a=3.5deg+-5deg

----------

----------

a=3.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)When load lever is cancelled.

----------

aa=32mm

----------

a=30deg+-5deg b=33deg+-3deg c=(8.5deg)

----------

aa=32mm

----------

a=30deg+-5deg b=33deg+-3deg c=(8.5deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(70deg)

----------

aa=15deg

----------

a=(70deg)

Information:

Start By:a. remove oil panb. remove oil pump 1. Remove bolts (1) and bearing cap (2). Remove the bearing half from the cap.

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and the block.

2. Remove the upper half of the main bearings as follows:a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal oil passage. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. (See Guideline For Reusable Parts, Main And Connecting Rod Bearings, FORM No. SEBF8009 and SEBD0531). Both the center and two end main journals have no oil hole. To remove these bearings, put a thin piece of soft material, (that will not damage the crankshaft journal), against the end of the bearing opposite the tab. Hit the bearing with the soft material until the tab of the bearing is free from the groove in the block. The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearing caps and cylinder block.3. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearing (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.4. Clean the surface of the main bearing caps for the main bearings. Install the new lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing.

Install the main bearing caps with the sequence number to the right, 1 through 7, front to rear.

5. Put main bearing caps (2) in position on the cylinder block. Put engine oil on the bolt threads and the contact surfaces of the bolt heads, and install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 54 7 N m (40 5 lb.ft.). Tighten the bolts on the opposite side to a torque of 54 7 N m (40 5 lb.ft.).6. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn. 8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.07 to 0.24 mm (.003 to .009 in.). The end play is controlled by the thrust bearings, which are part of main bearing No. six.End By:a. install oil pumpb. install oil pan

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and the block.

2. Remove the upper half of the main bearings as follows:a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal oil passage. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. (See Guideline For Reusable Parts, Main And Connecting Rod Bearings, FORM No. SEBF8009 and SEBD0531). Both the center and two end main journals have no oil hole. To remove these bearings, put a thin piece of soft material, (that will not damage the crankshaft journal), against the end of the bearing opposite the tab. Hit the bearing with the soft material until the tab of the bearing is free from the groove in the block. The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearing caps and cylinder block.3. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearing (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.4. Clean the surface of the main bearing caps for the main bearings. Install the new lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing.

Install the main bearing caps with the sequence number to the right, 1 through 7, front to rear.

5. Put main bearing caps (2) in position on the cylinder block. Put engine oil on the bolt threads and the contact surfaces of the bolt heads, and install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 54 7 N m (40 5 lb.ft.). Tighten the bolts on the opposite side to a torque of 54 7 N m (40 5 lb.ft.).6. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn. 8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.07 to 0.24 mm (.003 to .009 in.). The end play is controlled by the thrust bearings, which are part of main bearing No. six.End By:a. install oil pumpb. install oil pan