Information injection-pump assembly

ZEXEL

106671-1922

1066711922

ISUZU

1156028602

1156028602

Rating:

Cross reference number

ZEXEL

106671-1922

1066711922

ISUZU

1156028602

1156028602

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.2

5.17

5.23

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(11.6)

Vist

V

2.11

2.11

2.11

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

136

135

137

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(7)

Vist

V

2.8

2.7

2.9

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

15

11.8

18.2

Max. variation between cylinders

%

0

-13

13

Test data Ex:

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=950++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8+-0.3deg R01=0/4 load R02=4/4 load

----------

L=1-0.2mm N2=800r/min C2=(8deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=950++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8+-0.3deg R01=0/4 load R02=4/4 load

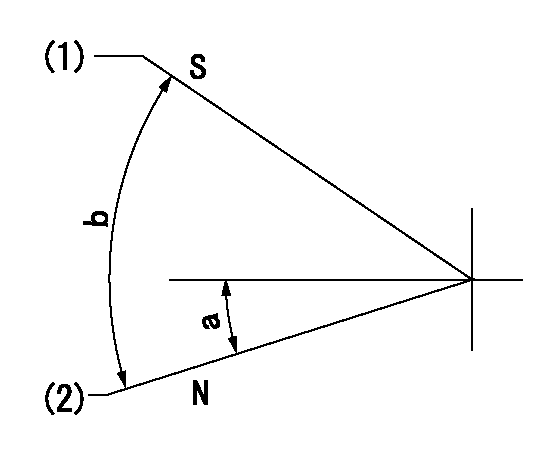

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=20mm

----------

a=17deg+-5deg b=37deg+-5deg

----------

aa=1mm bb=20mm

----------

a=17deg+-5deg b=37deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(100deg)

----------

aa=6deg

----------

a=(100deg)

Stop lever angle

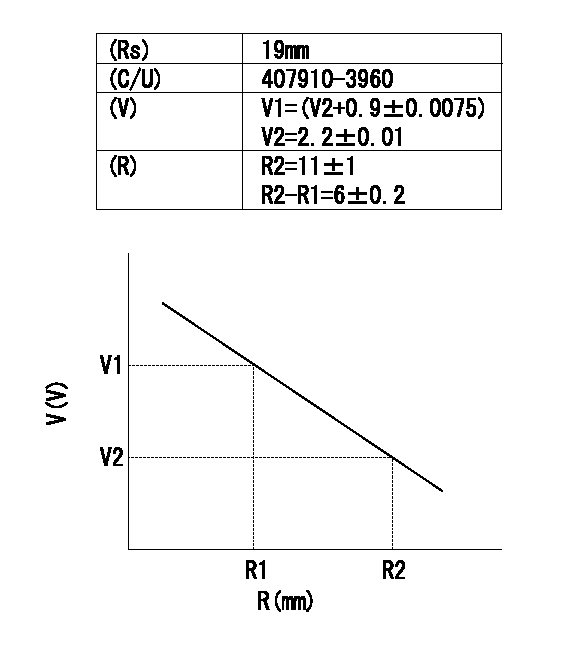

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

1. Loosen bolts (1) and (2) on belt tightener (3), remove belt (4). 2. Loosen the hose clamp at the water temperature regulator and the water pump. Remove four bolts (5) and remove water pump. The following steps are for the installation of the water pump and belt.3. Position the water pump with two o-ring seals (6) in place. Install four bolts (5) and tighten evenly. Tighten the hose clamp at the water temperature regulator and the water pump.4. Use a breaker bar in square drive slot (7) to apply belt tension, then tighten bolts (1) and (2). To adjust belt to proper tension, see the V-Belt Tension Chart in the Specifications section of this service manual for the correct tension on the belt.End By:a. install belt (Poly-Rib) and tensionerDisassemble And Assemble Water Pump

Start By:a. remove water pump and belt 1. Remove four bolts and remove rear cover (1) with gasket from the water pump.

When pressing the water pump apart do not allow the shaft and pulley to fall to the floor, damage may occur to the pulley.

2. Position water pump in a press. Use spacer plates to level the water pump. Using a small plate from Driver Set (A), press shaft (2) and pulley (3) out of impeller (4). Remove impeller (4).3. Continue to press shaft (2) and pulley (3) out of seal (5) and the water pump housing.4. Use the handle from Driver Set (B) to remove seal (5) from the water pump housing.5. Press shaft (2) and bearing assembly from pulley (3). The following steps are for the assembly of the water pump.6. Press shaft (2) and bearing assembly into pulley (3) until the end of the shaft is flush with the pulley (as illustrated).7. Press shaft (2) and bearing assembly with pulley (3) into water pump housing to the correct pulley position (as illustrated).8. Using Water Pump Seal Installer (C), install seal (5). Press impeller (4) onto shaft (2) to the correct impeller position (as illustrated).9. Position gasket and cover (1) and install the four bolts.End By:a. install water pump and belt

Start By:a. remove water pump and belt 1. Remove four bolts and remove rear cover (1) with gasket from the water pump.

When pressing the water pump apart do not allow the shaft and pulley to fall to the floor, damage may occur to the pulley.

2. Position water pump in a press. Use spacer plates to level the water pump. Using a small plate from Driver Set (A), press shaft (2) and pulley (3) out of impeller (4). Remove impeller (4).3. Continue to press shaft (2) and pulley (3) out of seal (5) and the water pump housing.4. Use the handle from Driver Set (B) to remove seal (5) from the water pump housing.5. Press shaft (2) and bearing assembly from pulley (3). The following steps are for the assembly of the water pump.6. Press shaft (2) and bearing assembly into pulley (3) until the end of the shaft is flush with the pulley (as illustrated).7. Press shaft (2) and bearing assembly with pulley (3) into water pump housing to the correct pulley position (as illustrated).8. Using Water Pump Seal Installer (C), install seal (5). Press impeller (4) onto shaft (2) to the correct impeller position (as illustrated).9. Position gasket and cover (1) and install the four bolts.End By:a. install water pump and belt