Information injection-pump assembly

BOSCH

9 400 616 735

9400616735

ZEXEL

106671-1910

1066711910

ISUZU

1156029420

1156029420

Rating:

Service parts 106671-1910 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-320-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}/22.1{225}

14.

NOZZLE

Include in #1:

106671-1910

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 735

9400616735

ZEXEL

106671-1910

1066711910

ISUZU

1156029420

1156029420

Zexel num

Bosch num

Firm num

Name

106671-1910

9 400 616 735

1156029420 ISUZU

INJECTION-PUMP ASSEMBLY

6SD1-MTC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6SD1-MTC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.17

4.23

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

220

218

222

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

106.6

106.6

Boost pressure

mmHg

800

800

Injection quantity adjustment_02

Adjusting point

B

Rack position

6+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

14

12

16

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

10.4

Boost pressure

kPa

45.3

42.6

48

Boost pressure

mmHg

340

320

360

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

12

Boost pressure

kPa

93.3

93.3

93.3

Boost pressure

mmHg

700

700

700

Timer adjustment

Pump speed

r/min

1150++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1150.

Do not advance until starting N = 1150.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0.5

0.5

0.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator excessive fuel lever setting: L1 (at boost pressure 0)

(5)Boost compensator stroke: BCL

(6)Set idle sub-spring

(7)Main spring setting

(8)Damper spring setting

----------

RT=1 TH=2.5mm L1=12.2+0.2mm BCL=1.6+-0.1mm

----------

----------

RT=1 TH=2.5mm L1=12.2+0.2mm BCL=1.6+-0.1mm

----------

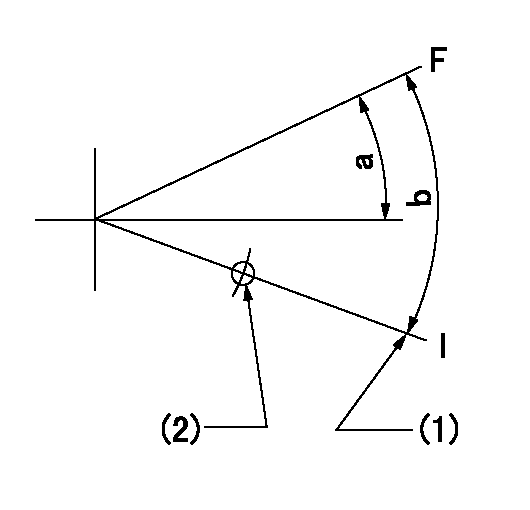

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=85mm

----------

a=9.5deg+-5deg b=16deg+-5deg

----------

aa=85mm

----------

a=9.5deg+-5deg b=16deg+-5deg

0000000901

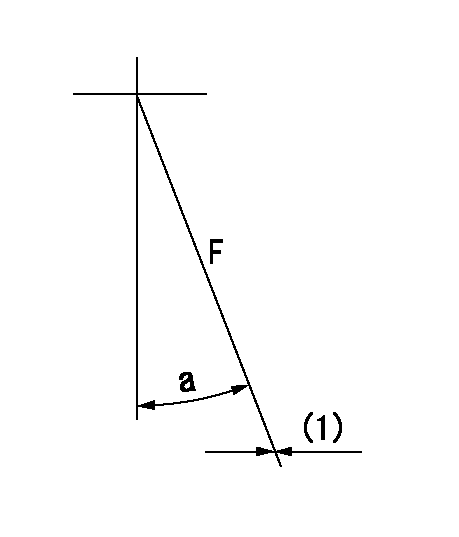

F:Full load

(1)Fix using the stopper bolt.

----------

----------

a=(31deg)+-5deg

----------

----------

a=(31deg)+-5deg

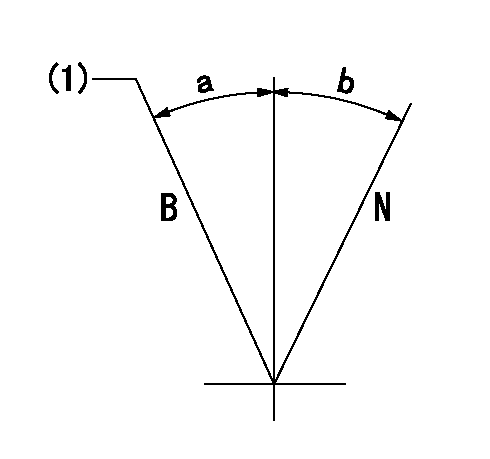

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

----------

aa=12.2+0.2mm

----------

a=(15deg) b=(15deg)

----------

aa=12.2+0.2mm

----------

a=(15deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(40deg)

----------

aa=14deg

----------

a=(40deg)

Information:

8T0900 AC/DC Clamp-On AmmeterThe 8T0900 AC/DC Clamp-On Ammeter is a completely portable, self-contained instrument that allows electrical current measurements to be made without breaking the circuit or disturbing the insulation on conductors. A digital display is located on the ammeter for reading current directly in a range from 1 to 1200 amperes. If a optional 6V6014 Cable is connected between this ammeter and one of the digital multimeters, current readings of less than 1 ammeter can then be read directly from the display of the multimeter.A lever is used to open the jaws over the conductor [up to a diameter of 19 mm (.75 in)], and the spring loaded jaws are then closed around the conductor for current measurement. A trigger switch that can be locked in the ON or OFF position is used to turn on the ammeter. When the turn-on trigger is released, the last current reading is held on the display for 5 seconds. This allows accurate measurements to be taken in limited access areas where the digital display is not visible to the operator. A zero control is provided for DC operation, and power for the ammeter is supplied by batteries located inside the handle. Make reference to Special Instruction, Form No. SEHS8420 for more complete information for use of the 8T0900 Clamp-On Ammeter.

6V7070 Heavy-Duty Digital MultimeterThe 6V7070 Heavy-Duty Digital Multimeter is a completely portable, hand held instrument with a digital display. This multimeter is built with extra protection against damage in field applications, and is equipped with seven functions and 29 ranges. The 6V7070 Multimeter has an instant ohms indicator that permits continuity checking for fast circuit inspection. It also can be used for troubleshooting small value capacitors.The 6V7800 Regular-duty Digital Multimeter (a low cost option to the Heavy-Duty Multimeter) is also available; however, the 6V7800 Multimeter does not have the 10A range or the instant ohms feature of the 6V7070 Multimeter. Make reference to Special Instruction, Form No. SEHS7734 for more complete information for use of the 6V7070 and 6V7800 Multimeters.Battery

Never disconnect any charging unit circuit or battery circuit cable from battery when the charging unit is operated. A spark can cause an explosion from the flammable vapor mixture of hydrogen and oxygen that is released from the electrolyte through the battery outlets. Injury to personnel can be the result.

The battery circuit is an electrical load on the charging unit. The load is variable because of the condition of the charge in the battery. Damage to the charging unit will result if the connections (either positive or negative) between the battery and charging unit are broken while the charging unit is in operation. This is because the battery load is lost and there is an increase in charging voltage. High voltage will damage, not only the charging unit, but also the regulator and other electrical components.Use the 6V4930 Battery Load Tester, the 8T900 Clamp-On Ammeter and the 6V7070 Multimeter to load test a battery that does not hold a charge when in

Have questions with 106671-1910?

Group cross 106671-1910 ZEXEL

Isuzu

106671-1910

9 400 616 735

1156029420

INJECTION-PUMP ASSEMBLY

6SD1-MTC

6SD1-MTC