Information injection-pump assembly

BOSCH

9 400 619 690

9400619690

ZEXEL

106671-1830

1066711830

Rating:

Service parts 106671-1830 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-303-2

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106671-1830

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 690

9400619690

ZEXEL

106671-1830

1066711830

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

434

431

437

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

173.3

173.3

Boost pressure

mmHg

1300

1300

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

4.8

11.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

225.5

222.5

228.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

8.3

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(12)

Boost pressure

kPa

149.3

149.3

149.3

Boost pressure

mmHg

1120

1120

1120

Timer adjustment

Pump speed

r/min

1050++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1050.

Do not advance until starting N = 1050.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1

1

1

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

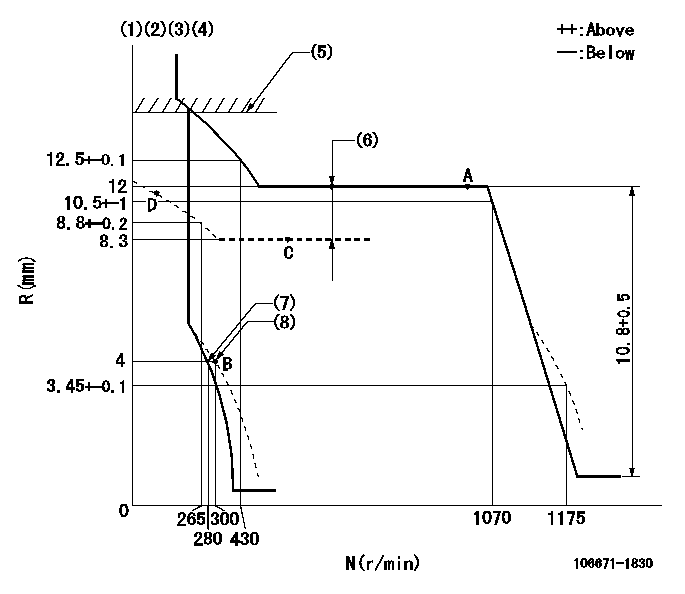

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Deliver with the damper spring not operating.

(5)Boost compensator excessive fuel lever setting: L1 (at boost pressure 0)

(6)Boost compensator stroke: BCL

(7)Main spring setting

(8)Set idle sub-spring

----------

RT=1 TH=2.5mm L1=13.6+-0.1mm BCL=(3.7)+-0.1mm

----------

----------

RT=1 TH=2.5mm L1=13.6+-0.1mm BCL=(3.7)+-0.1mm

----------

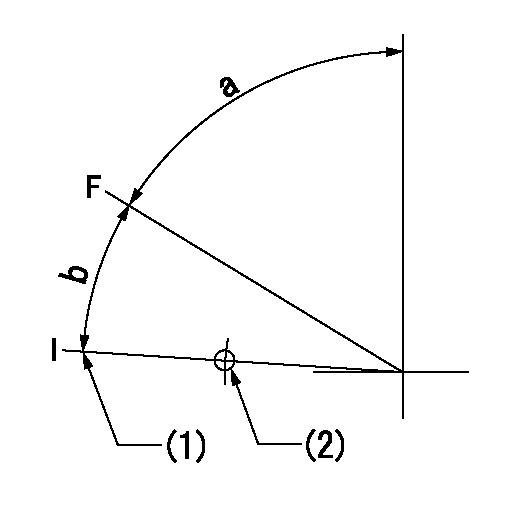

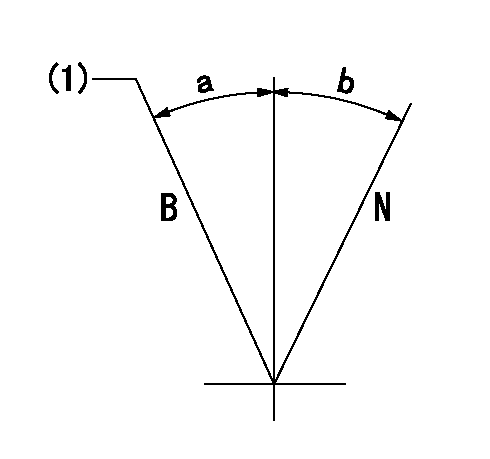

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=85.1mm

----------

a=72.5deg+-5deg b=15deg+-5deg

----------

aa=85.1mm

----------

a=72.5deg+-5deg b=15deg+-5deg

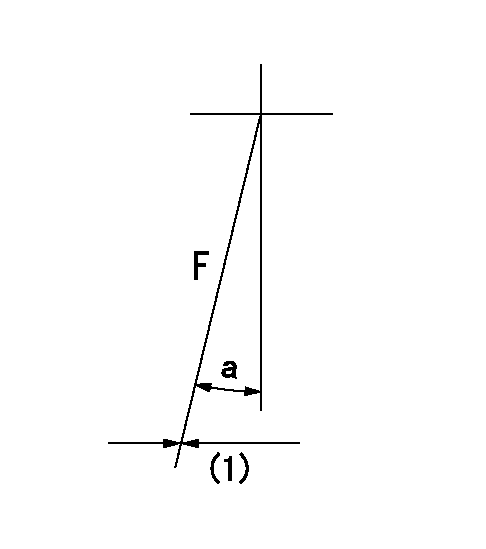

0000000901

F:Full load

(1)Fix using the stopper bolt.

----------

----------

a=(19deg)+-5deg

----------

----------

a=(19deg)+-5deg

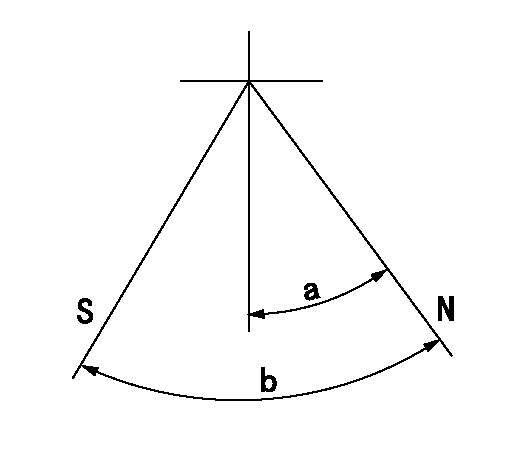

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

----------

aa=13.6+-0.1mm

----------

a=(15deg) b=(15deg)

----------

aa=13.6+-0.1mm

----------

a=(15deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(70deg)

----------

aa=15deg

----------

a=(70deg)

Information:

Start By:a. remove flywheel housingb. remove oil pan platec. remove camshaft

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the camshaft bearings from the cylinder block with tooling (A). Start with the front bearing and work to the rear. The following steps are for the installation of the camshaft bearings.2. Use tooling (A) to install the camshaft bearings in the cylinder block. 3. Install the camshaft bearings in the cylinder block as follows:a. Install the front bearing to a depth of 0.5 0.5 mm (.02 .02 in) and with the oil holes in a horizontal position and the joint at the top of the engine. The joint can not be more than 15° from vertical in either direction.b. Install the remainder of the bearings. Install the bearings to the dimensions given from the front face of the cylinder block: A) 154.0 0.5 mm (6.06 .02 in), B) 303.2 0.5 mm (11.94 .02 in), C) 601.7 0.5 mm (23.69 .02 in), D) 903.4 0.5 mm (35.57 .02 in).End By:a. install camshaftb. install oil pan platec. install flywheel housing

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the camshaft bearings from the cylinder block with tooling (A). Start with the front bearing and work to the rear. The following steps are for the installation of the camshaft bearings.2. Use tooling (A) to install the camshaft bearings in the cylinder block. 3. Install the camshaft bearings in the cylinder block as follows:a. Install the front bearing to a depth of 0.5 0.5 mm (.02 .02 in) and with the oil holes in a horizontal position and the joint at the top of the engine. The joint can not be more than 15° from vertical in either direction.b. Install the remainder of the bearings. Install the bearings to the dimensions given from the front face of the cylinder block: A) 154.0 0.5 mm (6.06 .02 in), B) 303.2 0.5 mm (11.94 .02 in), C) 601.7 0.5 mm (23.69 .02 in), D) 903.4 0.5 mm (35.57 .02 in).End By:a. install camshaftb. install oil pan platec. install flywheel housing

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.