Information injection-pump assembly

ZEXEL

106671-1291

1066711291

ISUZU

1156011921

1156011921

Rating:

Cross reference number

ZEXEL

106671-1291

1066711291

ISUZU

1156011921

1156011921

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

128.5

126.9

130.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

13

11

15

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

8.9

Boost pressure

kPa

13.3

12

14.6

Boost pressure

mmHg

100

90

110

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

10.3

Boost pressure

kPa

46.7

40

53.4

Boost pressure

mmHg

350

300

400

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3

3

3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

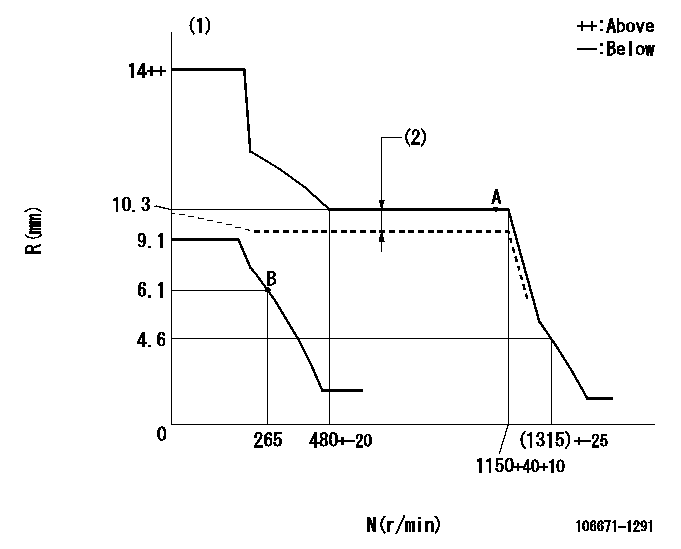

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Boost compensator stroke: BCL

----------

K=6 BCL=1.4+-0.1mm

----------

----------

K=6 BCL=1.4+-0.1mm

----------

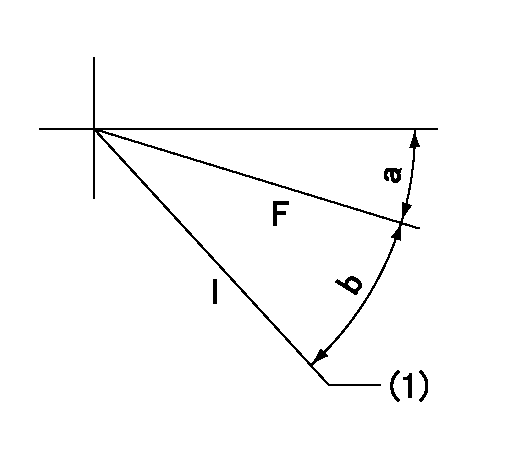

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=25deg+-5deg

----------

----------

a=7deg+-5deg b=25deg+-5deg

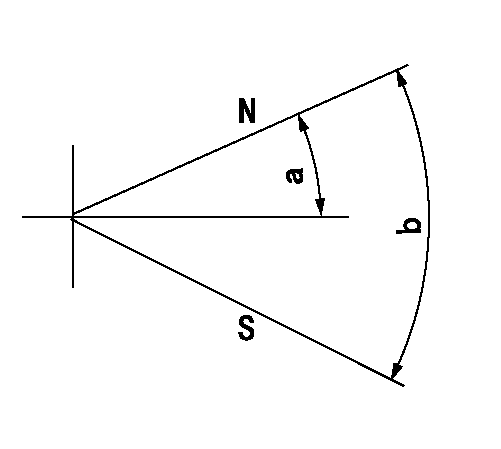

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Positions of coupling's threaded installation holes at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(40deg)

----------

aa=11deg

----------

a=(40deg)

Information:

preparatory steps: a) remove flywheel housingb) remove timing gear coverc) remove pistons1. Lay the engine on its side or top in a suitable stand.2. Attach a hoist to the crankshaft. 3. Remove the main bearing caps (1). 4. Remove the crankshaft-weight 200 lbs. (91 kg).5. Remove the crankshaft main bearings from the cylinder block and main bearing caps.

If the main bearings are not going to be replaced mark them with respect to their location in the engine.

6. Using tool setup (A), remove the crankshaft gear and oil seal wear sleeve.Install Crankshaft

1. Heat the crankshaft gear and the oil seal wear sleeve, maximum 600°F (316°C), and install them on the crankshaft.2. Clean the bearing seating surfaces in the cylinder block and the main bearing caps. Install the upper and lower halves of the bearings in the cylinder block bearing caps. Lubricate the bearings with clean SAE 30 engine oil.

If the main bearings are not being replaced the original bearings must be installed in the same location they were removed from.

3. Attach a hoist and position the crankshaft in the cylinder block with the timing marks (1) aligned. 4. Using wire (A), check the main bearing clearance. Install the caps in the respective positions with the number stamped on cap facing the corresponding number cast on side of the cylinder block web. 5. Lubricate the threads of bearing cap retaining bolts and face of washers with clean SAE 30 engine oil. Install the retaining bolts and washers. Tighten both bolts to 30 3 lb. ft. (4,1 0,4 mkg). Mark both bolt heads and bearing caps then tighten each bolt an additional 90° from mark. Remove bearing caps and measure thickness of wire (A). Main bearing clearance should be .0030-.0059 in. (0,076-0,150 mm).6. Lubricate the lower halves of main bearings with clean SAE 30 engine oil. Install main bearing caps in their respective positions. Install cap retaining bolts and washers. Tighten both bolts to 30 3 lb. ft. (4,1 0,4 mkg). Mark both bolt heads and bearing caps then tighten each bolt an additional 90° from mark. 7. Using tool setup (B), check the crankshaft end play as controlled by thrust bearing (2) on rear main bearing. End play should be .0025-.0145 in. (0,064-0,368 mm). Maximum permissible end play is .025 in. (0,64 mm).concluding steps: a) install pistonsb) install timing gear coverc) install flywheel housingd) check fuel injection pump timing. See REMOVE AND INSTALL FUEL INJECTION PUMP HOUSING AND GOVERNOR AS A UNIT.

If the main bearings are not going to be replaced mark them with respect to their location in the engine.

6. Using tool setup (A), remove the crankshaft gear and oil seal wear sleeve.Install Crankshaft

1. Heat the crankshaft gear and the oil seal wear sleeve, maximum 600°F (316°C), and install them on the crankshaft.2. Clean the bearing seating surfaces in the cylinder block and the main bearing caps. Install the upper and lower halves of the bearings in the cylinder block bearing caps. Lubricate the bearings with clean SAE 30 engine oil.

If the main bearings are not being replaced the original bearings must be installed in the same location they were removed from.

3. Attach a hoist and position the crankshaft in the cylinder block with the timing marks (1) aligned. 4. Using wire (A), check the main bearing clearance. Install the caps in the respective positions with the number stamped on cap facing the corresponding number cast on side of the cylinder block web. 5. Lubricate the threads of bearing cap retaining bolts and face of washers with clean SAE 30 engine oil. Install the retaining bolts and washers. Tighten both bolts to 30 3 lb. ft. (4,1 0,4 mkg). Mark both bolt heads and bearing caps then tighten each bolt an additional 90° from mark. Remove bearing caps and measure thickness of wire (A). Main bearing clearance should be .0030-.0059 in. (0,076-0,150 mm).6. Lubricate the lower halves of main bearings with clean SAE 30 engine oil. Install main bearing caps in their respective positions. Install cap retaining bolts and washers. Tighten both bolts to 30 3 lb. ft. (4,1 0,4 mkg). Mark both bolt heads and bearing caps then tighten each bolt an additional 90° from mark. 7. Using tool setup (B), check the crankshaft end play as controlled by thrust bearing (2) on rear main bearing. End play should be .0025-.0145 in. (0,064-0,368 mm). Maximum permissible end play is .025 in. (0,64 mm).concluding steps: a) install pistonsb) install timing gear coverc) install flywheel housingd) check fuel injection pump timing. See REMOVE AND INSTALL FUEL INJECTION PUMP HOUSING AND GOVERNOR AS A UNIT.