Information injection-pump assembly

BOSCH

9 400 613 475

9400613475

ZEXEL

106671-0596

1066710596

NISSAN-DIESEL

1671396774

1671396774

Rating:

Service parts 106671-0596 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660096520

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106671-0596

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 613 475

9400613475

ZEXEL

106671-0596

1066710596

NISSAN-DIESEL

1671396774

1671396774

Zexel num

Bosch num

Firm num

Name

106671-0596

9 400 613 475

1671396774 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PE6T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

PE6T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

154.8

152.8

156.8

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_02

Adjusting point

C

Rack position

10.4

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

117.4

115.4

119.4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

8.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

15

14

16

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.4

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12.3+0.2

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

Timer adjustment

Pump speed

r/min

1150++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1150.

Do not advance until starting N = 1150.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

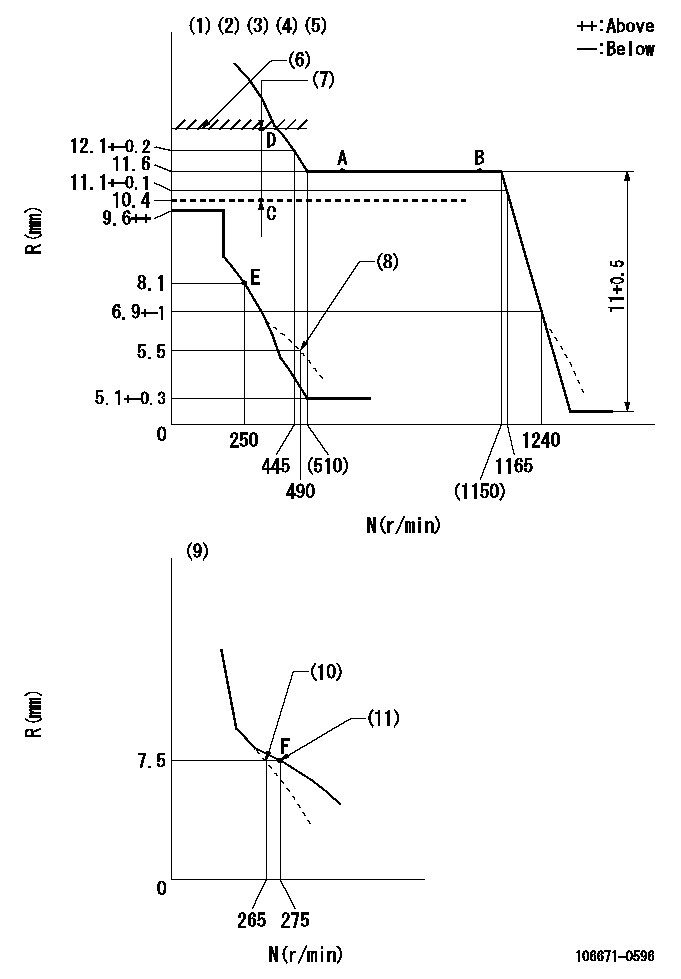

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Maximum - minimum speed specification (using speed lever at adjustment)

(2)Lever ratio: RT

(3)Target shim dimension: TH

(4)Tolerance for racks not indicated: +-0.05mm.

(5)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

(6)Rack limit using the stop lever: R1

(7)Boost compensator stroke: BCL

(8)Damper spring setting

(9)Variable speed specification: idling adjustment

(10)Main spring setting

(11)Set idle sub-spring

----------

RT=1 TH=1.9mm R1=12.3+0.2mm BCL=2+-0.1mm

----------

----------

RT=1 TH=1.9mm R1=12.3+0.2mm BCL=2+-0.1mm

----------

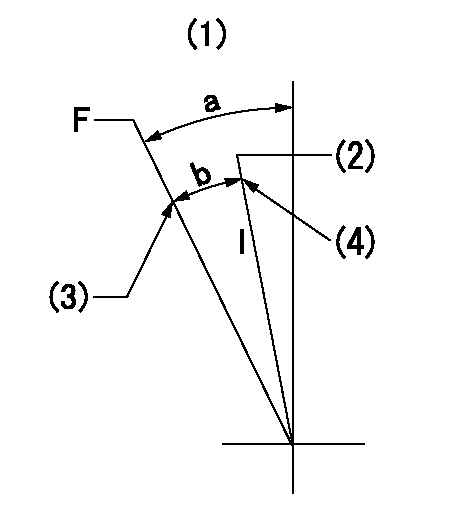

Speed control lever angle

F:Full speed

I:Idle

(1)Base lever only

(2)Set the pump speed at aa

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=275r/min

----------

a=23deg+-5deg b=17deg+-5deg

----------

aa=275r/min

----------

a=23deg+-5deg b=17deg+-5deg

0000000901

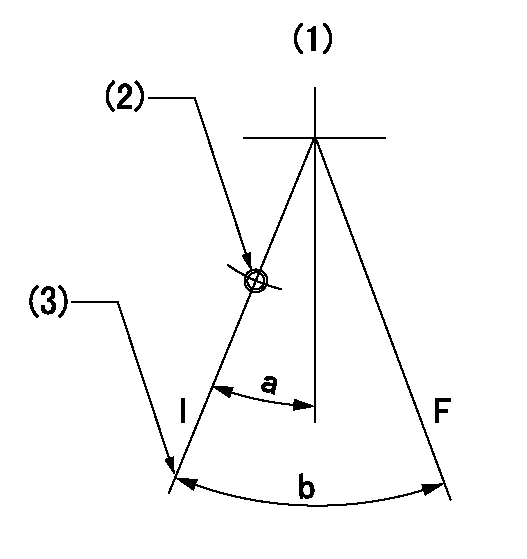

F:Full load

I:Idle

(1)Base lever only

(2)At threaded hole above R = aa

(3)Stopper bolt setting

----------

aa=31mm

----------

a=15deg+-5deg b=24.5deg+-3deg

----------

aa=31mm

----------

a=15deg+-5deg b=24.5deg+-3deg

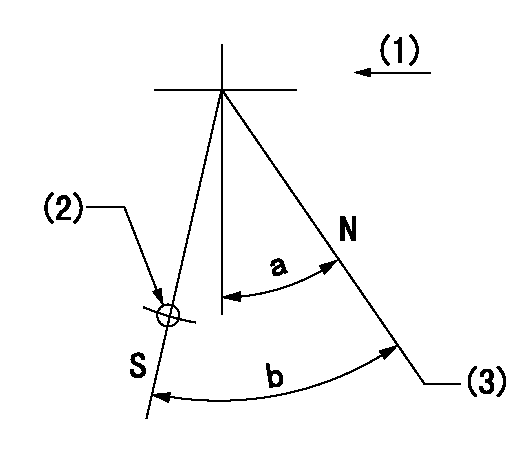

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

(2)Use the hole at R = aa

(3)Rack position = bb (set the stopper bolt at point D).

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

BRAKESAVER CONTROL VALVE IN FLOW CONTROL POSITION

1. Passage to oil filter. 2. Oil cooler. 3. Air line. 4. Oil inlet passage. 5. Valve spool. 6. Control valve body. 7. Differential pressure valve. 8. Poppet valve. 9. BrakeSaver. 10. BrakeSaver inlet pressure. 11. BrakeSaver outlet pressure.BrakeSaver Operator Controls

Two types of controls are available for the BrakeSaver: a manual control and an automatic control. Supply air goes into the circuit through pressure reducing valve (17). The pressure reducing valve keeps a maximum pressure in the control circuit of 40 psi (280 kPa).This pressure air is available at manual control lever (2) in the operator's compartment and at the solenoid valve (8). When ignition switch (5) is turned ON, the electrical circuit to manual-automatic switch (3) has current available. [Switch (3) is shown in the MANUAL position.] In the MANUAL position, switch (3) opens the circuit. The automatic section of switch (3) is in the OFF position and the BrakeSaver can only be operated manually. Maximum supply air pressure from the air compressor (not shown) is 125 psi (860 kPa).

BRAKESAVER CONTROL CIRCUIT SCHEMATIC

1. Pressure reducing valve. 2. Manual control lever. 3. Manual-automatic selector switch. 4. Control valve. 5. Ignition switch. 6. Double check valve. 7. Accelerator switch. 8. Solenoid valve. 9. Clutch switch.Manual Control

When the BrakeSaver manual-automatic selector switch (3) is in the MANUAL position, the BrakeSaver can only be turned on by the operator by moving manual control lever (2). With control lever (2) in the BrakeSaver ON position, air goes through manual control lever (2) and double check valve (6) to control valve (4). A valve spool moves and the BrakeSaver gets oil. It holds this oil until manual control lever (2) is moved to the BrakeSaver OFF position. Air can go from control valve (4) to the atmosphere through manual control lever (2).The farther control lever (2) is moved toward the ON position, the higher the pressure of the air sent to the control valve. An increase in air pressure in the control valve causes an increase in the oil pressure in the BrakeSaver. An increase in the oil pressure in the BrakeSaver causes an increase in the braking force in the BrakeSaver. The operator can give modulation to the braking force in the BrakeSaver through the movement of control lever (2).An air pressure gauge gives the operator a relative indication of the air pressure being sent to the control valve. Through the use of the indication on the air pressure gauge in relation to engine rpm, the operator can get approximately the same braking effect from the BrakeSaver time after time. This lets the operator more easily control the desired wheel speed of the vehicle.An oil temperature gauge gives the operator an indication of the ability of the engine cooling system to control the heat in the BrakeSaver during its operation. If the gauge reads too HOT, move control lever (2) to the OFF position and use the service brakes to control the wheel speed of the

Have questions with 106671-0596?

Group cross 106671-0596 ZEXEL

Nissan-Diesel

106671-0596

9 400 613 475

1671396774

INJECTION-PUMP ASSEMBLY

PE6T

PE6T