Information injection-pump assembly

ZEXEL

106671-0594

1066710594

Rating:

Service parts 106671-0594 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96520

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106671-0594

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-0594

1066710594

Zexel num

Bosch num

Firm num

Name

106671-0594

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF85119/A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

154.8

152.8

156.8

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_02

Adjusting point

C

Rack position

10.4

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

117.4

115.4

119.4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

8.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

15

14

16

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.4

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12.3+0.2

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

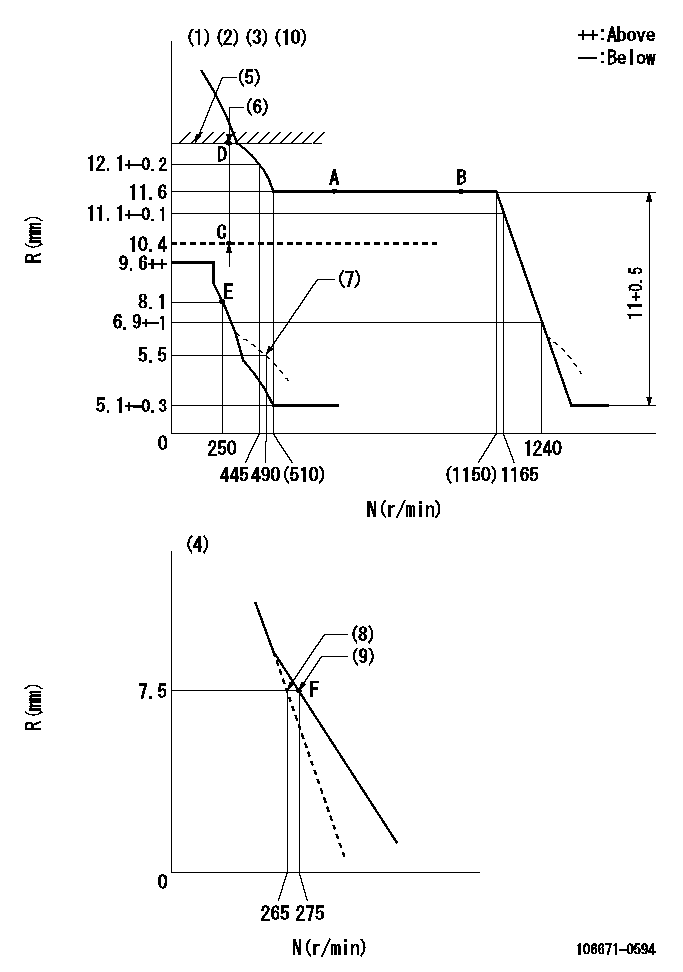

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Variable speed specification: idling adjustment

(5)Rack limit using the stop lever: R1

(6)Boost compensator stroke: BCL

(7)Damper spring setting

(8)Main spring setting

(9)Set idle sub-spring

(10)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

----------

RT=1 TH=1.9mm R1=12.3+0.2mm BCL=2+-0.1mm

----------

----------

RT=1 TH=1.9mm R1=12.3+0.2mm BCL=2+-0.1mm

----------

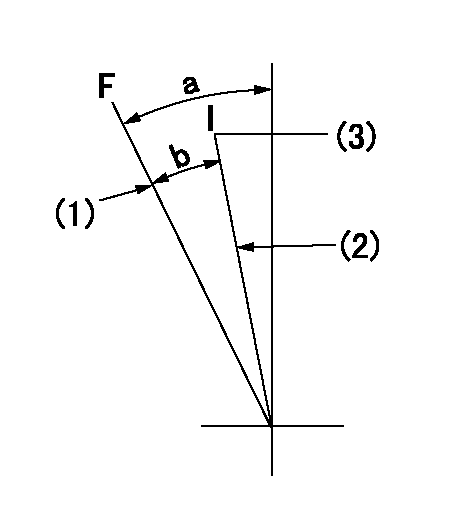

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)Set the pump speed at aa

----------

aa=275r/min

----------

a=23deg+-5deg b=17deg+-5deg

----------

aa=275r/min

----------

a=23deg+-5deg b=17deg+-5deg

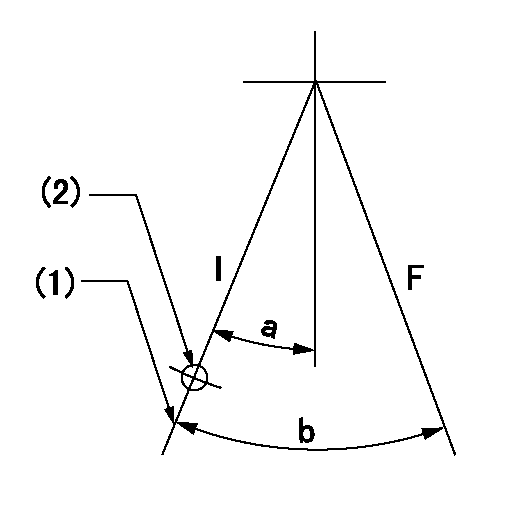

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)At center of threaded hole above R = aa

----------

aa=17mm

----------

a=15deg+-5deg b=24.5deg+-3deg

----------

aa=17mm

----------

a=15deg+-5deg b=24.5deg+-3deg

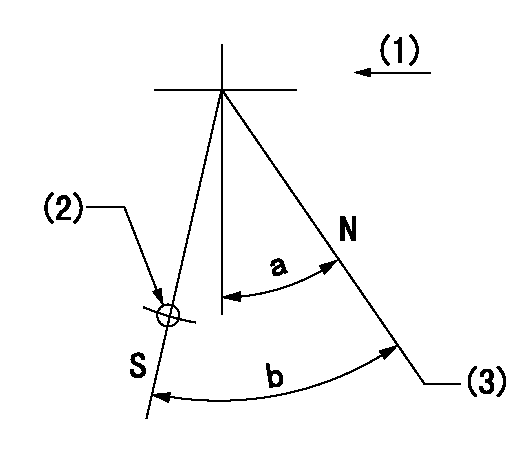

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Drive side

(3)Rack position bb

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Make reference to ANALYZING TURBOCHARGER FAILURE, Form No. FEG45138.(1) See TURBOCHARGER IMPELLER INSTALLATION.(2) Torque for bolts holding thrust plate ... 40 5 lb. in.(4.5 0.6 N m)(3) Tighten bolt holding band clamp to ... 120 10 lb. in.(14 1 N m)(4) Put 9M3710 or 4S9416 Anti-Seize Compound on threads of bolts holding turbine housing and tighten to ... 175 15 lb. in.(20 2 N m)(5) Put 9M3710 or 4S9416 Anti-Seize Compound on threads of bolts holding turbocharger to manifold and tighten to ... 40 4 lb. ft.(55 5 N m)(6) End play for shaft (new) ... .006 to .011 in.(0.15 to 0.27 mm)(7) Bore in the bearing ... .6268 to .6272 in.(15.921 to 15.931 mm) Diameter of surface on shaft (journal) for the bearing ... .6250 to .6254 in.(15.875 to 15.885 mm)(8) Bore in housing ... .9827 to .9832 in.(24.961 to 24.973 mm) Outside diameter of the bearing ... .9780 to .9785 in.(24.841 to 24.854 mm)(9) Clearance between ends of oil seal ring ... .008 to .015 in.(0.20 to 0.38 mm) The radial clearance for the shaft is .004 to .009 in. (0.10 to 0.23 mm).(AiResearch TV81)

(1) Nut for impeller (See TURBOCHARGER IMPELLER INSTALLATION) Do not bend or add stress to the shaft when nut is tightened.(2) Torque for the bolts that hold the backplate ... 90 10 lb.in.(10 1 N m)(3) Torque for the clamp bolts ... 10 1 lb. ft.(14 1 N m)(4) Bore in the bearings ... .6268 to .6272 in.(15.921 to 15.931 mm) Diameter for the surfaces (journals) on the shaft for the bearings ... .6250 to .6254 in.(15.875 to 15.885 mm)(5) Bore in the housing ... .9827 to .9832 in.(24.961 to 24.973 mm) Outside diameter of the bearings ... .9782 to .9787 in.(24.846 to 24.859 mm)(6) Clearance between the ends of the oil seal ring ... .008 to .015 in.(0.20 to 0.38 mm)(7) End play for the shaft ... .003 to .010 in.(0.08 to 0.25 mm)(8) Torque for support nuts (put 9M3710 or 4S9416 Anti-Seize Compound on the stud threads) ... 40 4 lb. ft.(55 5 N m)(AiResearch T1810)

Make reference to ANALYZING TURBOCHARGER FAILURE. Form No. FEG45138.(1) End play for shaft ... .0065 .0025 in.(0.165 0.063 mm) Radial clearance for the shaft ... .004 to .009 in.(0.10 to 0.23 mm)(2) Bore in the bearing ... .6268 to .6272 in.(15.921 to 15.931 mm) Diameter of surface on shaft (journal) for the bearing ... .6250 to .6254 in.(15.875 to 15.885 mm)(3) Put 8S6747 Gasket Sealer on bolts holding compressor housing and tighten to ... 105 5 lb. in.(11.9 0.6 N m)(4) Put 9M3710 or 4S9416 Anti-Seize Compound on bolts holding turbine housing and tighten to ... 175 15 lb. in.(19.8 1.7 N m)(5) Put 9M3710 or 4S9416 Anti-Seize Compound on

(1) Nut for impeller (See TURBOCHARGER IMPELLER INSTALLATION) Do not bend or add stress to the shaft when nut is tightened.(2) Torque for the bolts that hold the backplate ... 90 10 lb.in.(10 1 N m)(3) Torque for the clamp bolts ... 10 1 lb. ft.(14 1 N m)(4) Bore in the bearings ... .6268 to .6272 in.(15.921 to 15.931 mm) Diameter for the surfaces (journals) on the shaft for the bearings ... .6250 to .6254 in.(15.875 to 15.885 mm)(5) Bore in the housing ... .9827 to .9832 in.(24.961 to 24.973 mm) Outside diameter of the bearings ... .9782 to .9787 in.(24.846 to 24.859 mm)(6) Clearance between the ends of the oil seal ring ... .008 to .015 in.(0.20 to 0.38 mm)(7) End play for the shaft ... .003 to .010 in.(0.08 to 0.25 mm)(8) Torque for support nuts (put 9M3710 or 4S9416 Anti-Seize Compound on the stud threads) ... 40 4 lb. ft.(55 5 N m)(AiResearch T1810)

Make reference to ANALYZING TURBOCHARGER FAILURE. Form No. FEG45138.(1) End play for shaft ... .0065 .0025 in.(0.165 0.063 mm) Radial clearance for the shaft ... .004 to .009 in.(0.10 to 0.23 mm)(2) Bore in the bearing ... .6268 to .6272 in.(15.921 to 15.931 mm) Diameter of surface on shaft (journal) for the bearing ... .6250 to .6254 in.(15.875 to 15.885 mm)(3) Put 8S6747 Gasket Sealer on bolts holding compressor housing and tighten to ... 105 5 lb. in.(11.9 0.6 N m)(4) Put 9M3710 or 4S9416 Anti-Seize Compound on bolts holding turbine housing and tighten to ... 175 15 lb. in.(19.8 1.7 N m)(5) Put 9M3710 or 4S9416 Anti-Seize Compound on

Have questions with 106671-0594?

Group cross 106671-0594 ZEXEL

106671-0594

INJECTION-PUMP ASSEMBLY