Information injection-pump assembly

ZEXEL

106671-0370

1066710370

Rating:

Cross reference number

ZEXEL

106671-0370

1066710370

Zexel num

Bosch num

Firm num

Name

106671-0370

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R2(11.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

154.3

150.3

158.3

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

174.4

172.4

176.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.1

9.1

11.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1(10.7)

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

120.6

118.6

122.6

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

12.3+0.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

173.8

163.8

183.8

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R1(10.7)

Boost pressure

kPa

4

Boost pressure

mmHg

30

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12.3+0.2

Boost pressure

kPa

17.3

17.3

17.3

Boost pressure

mmHg

130

130

130

Timer adjustment

Pump speed

r/min

200+100

Advance angle

deg.

1.6

1.1

2.1

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500-150

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

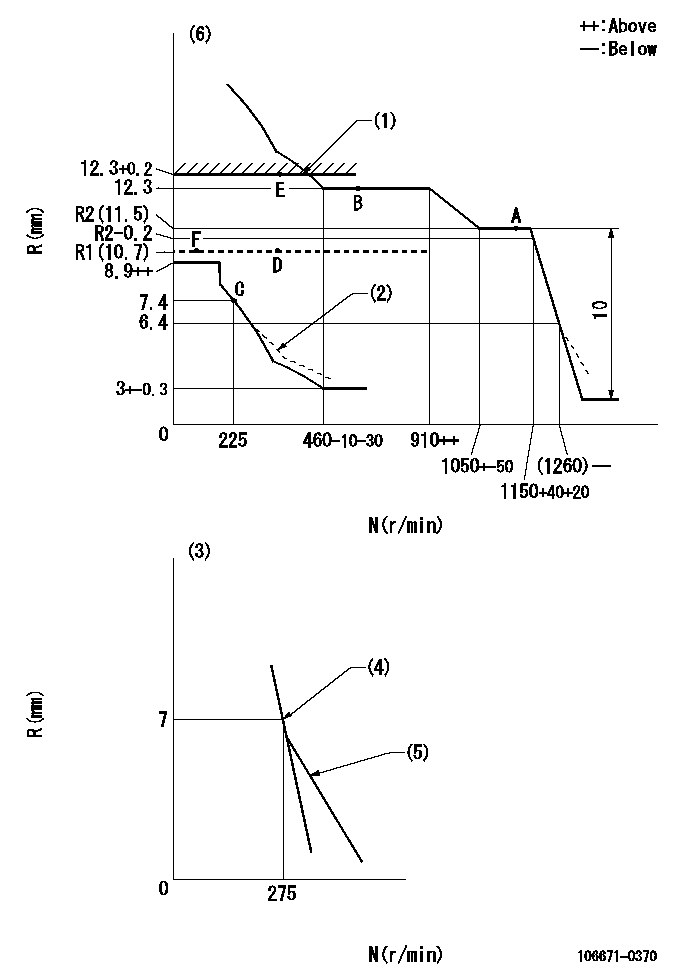

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack limit using stop lever

(2)Damper spring setting: DL

(3)Variable speed specification: idling adjustment

(4)Main spring setting

(5)Idle sub spring setting: L1.

(6)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

----------

DL=6.4-0.2mm L1=7-0.2mm

----------

----------

DL=6.4-0.2mm L1=7-0.2mm

----------

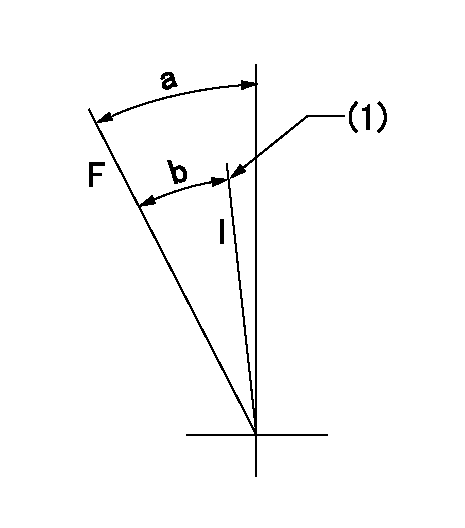

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=31deg+-5deg b=(24deg)+-5deg

----------

----------

a=31deg+-5deg b=(24deg)+-5deg

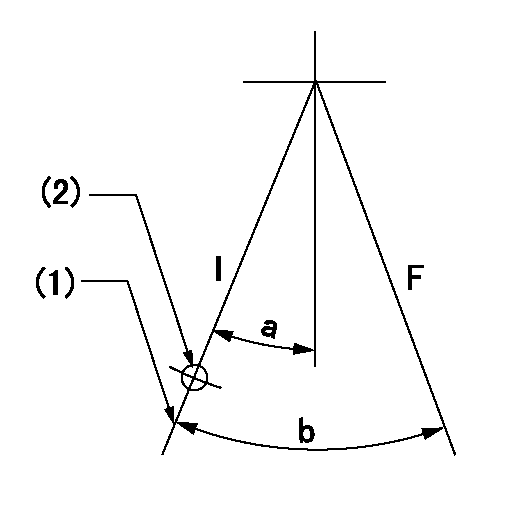

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)At threaded hole above R = aa

----------

aa=17mm

----------

a=22deg+-5deg b=34.5deg+-3deg

----------

aa=17mm

----------

a=22deg+-5deg b=34.5deg+-3deg

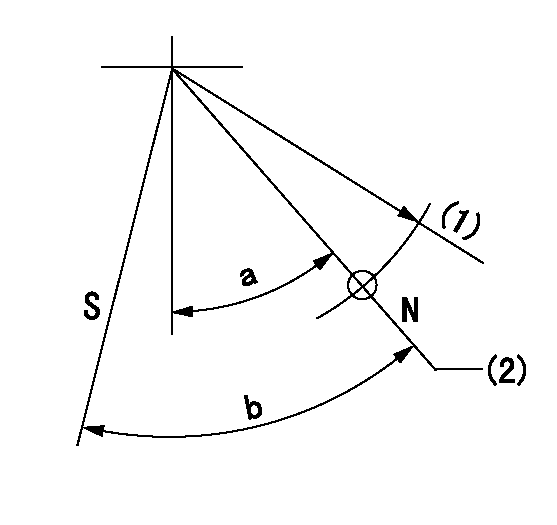

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)R = aa

(2)Rack position bb

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

2. Remove two short bolts (1) and two longer bolts (2) from manifold (3) and BrakeSaver housing.3. Remove the manifold from the control valve. 4. Remove the three bolts from elbows (5) and the control valve.5. Remove four bolts (4) that hold the control valve to the oil pan.6. Remove the control valve from under the oil pan.7. Make an inspection of the O-ring seals on the manifold and on the control valve. If there is wear or damage make a replacement of the O-ring seals.Install Brakesaver Control Valve

1. Put clean SAE 30 engine oil on O-ring seals (1).2. Put the control valve in position under the oil pan. Install the four bolts that hold the control valve to the oil pan.3. Install the elbow and the bolts that hold it to the side of the control valve. 4. Put SAE 30 engine oil on the O-ring seals of the manifold. Install manifold (2) in the control valve. Install the four bolts that hold the manifold to the BrakeSaver housing.5. Fill the engine with oil. See 3408 TRUCK ENGINE LUBRICATION AND MAINTENANCE GUIDE.Disassemble Brakesaver Control Valve

start by:a) remove BrakeSaver control valve 1. Remove O-ring seals (1) from the valve body.2. Remove four bolts (2) slowly and evenly from cover (4). Remove the cover.

Spring force is behind the cover at removal.

3. Remove cover (3) and the seal from the opposite end of the valve body. 4. Remove spool (8) as an assembly.5. Remove spring (7), stop (10), spring (6) and slug (9).6. Remove the seals and sleeve (5). 7. Remove bolt (11), plate (13) and diaphragm (12) from the spool. Make an inspection of the pin on the spool, and make a replacement of the pin if there is damage or wear.Assemble Brakesaver Control Valve

1. Install diaphragm (4) and plate (8) on valve spool (3). Make alignment of the hole in the plate valve with the pin on the spool. Install the bolt that holds the plate and the diaphragm in position.

When diaphragm (4) is installed on valve spool (3), make sure the fabric side is pulled down over the valve spool to make contact with it and the smooth (rubber coated) side is next to valve body.

2. Install sleeves (1) and the seals in the valve body. 3. Install the valve spool as an assembly into the valve body. As the valve spool is installed, make sure the edge of the diaphragm makes contact all the way around with the groove in the valve body. At this time the valve spool end must extend about 1.50 in. (38.1 mm) from the valve body. Push the valve spool about .25 in. (6.4 mm) - .50 in. (12.7 mm) farther into the valve body until a curved depression is caused between the valve spool and valve body. Make sure there are no wrinkles in the diaphragm. 4. Put cover (9) in position. Install the four bolts that hold the cover on the valve body. Move the valve spool in the

1. Put clean SAE 30 engine oil on O-ring seals (1).2. Put the control valve in position under the oil pan. Install the four bolts that hold the control valve to the oil pan.3. Install the elbow and the bolts that hold it to the side of the control valve. 4. Put SAE 30 engine oil on the O-ring seals of the manifold. Install manifold (2) in the control valve. Install the four bolts that hold the manifold to the BrakeSaver housing.5. Fill the engine with oil. See 3408 TRUCK ENGINE LUBRICATION AND MAINTENANCE GUIDE.Disassemble Brakesaver Control Valve

start by:a) remove BrakeSaver control valve 1. Remove O-ring seals (1) from the valve body.2. Remove four bolts (2) slowly and evenly from cover (4). Remove the cover.

Spring force is behind the cover at removal.

3. Remove cover (3) and the seal from the opposite end of the valve body. 4. Remove spool (8) as an assembly.5. Remove spring (7), stop (10), spring (6) and slug (9).6. Remove the seals and sleeve (5). 7. Remove bolt (11), plate (13) and diaphragm (12) from the spool. Make an inspection of the pin on the spool, and make a replacement of the pin if there is damage or wear.Assemble Brakesaver Control Valve

1. Install diaphragm (4) and plate (8) on valve spool (3). Make alignment of the hole in the plate valve with the pin on the spool. Install the bolt that holds the plate and the diaphragm in position.

When diaphragm (4) is installed on valve spool (3), make sure the fabric side is pulled down over the valve spool to make contact with it and the smooth (rubber coated) side is next to valve body.

2. Install sleeves (1) and the seals in the valve body. 3. Install the valve spool as an assembly into the valve body. As the valve spool is installed, make sure the edge of the diaphragm makes contact all the way around with the groove in the valve body. At this time the valve spool end must extend about 1.50 in. (38.1 mm) from the valve body. Push the valve spool about .25 in. (6.4 mm) - .50 in. (12.7 mm) farther into the valve body until a curved depression is caused between the valve spool and valve body. Make sure there are no wrinkles in the diaphragm. 4. Put cover (9) in position. Install the four bolts that hold the cover on the valve body. Move the valve spool in the

Have questions with 106671-0370?

Group cross 106671-0370 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-0370

INJECTION-PUMP ASSEMBLY