Information injection-pump assembly

BOSCH

9 400 616 656

9400616656

ZEXEL

106671-0263

1066710263

NISSAN-DIESEL

1680196561

1680196561

Rating:

Service parts 106671-0263 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106671-0263

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 656

9400616656

ZEXEL

106671-0263

1066710263

NISSAN-DIESEL

1680196561

1680196561

Zexel num

Bosch num

Firm num

Name

106671-0263

9 400 616 656

1680196561 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PE6T * K

PE6T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(11.8)

Vist

V

1.64

1.64

1.64

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

174.4

172.4

176.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(7.1)

Vist

V

2.58

2.48

2.68

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.1

9.1

11.1

Max. variation between cylinders

%

0

-10

10

Governor adjustment

Pump speed

r/min

200+100

Advance angle

deg.

1.6

1.1

2.1

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

500-150

Advance angle

deg.

0

0

0

Governor adjustment_03

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Governor adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

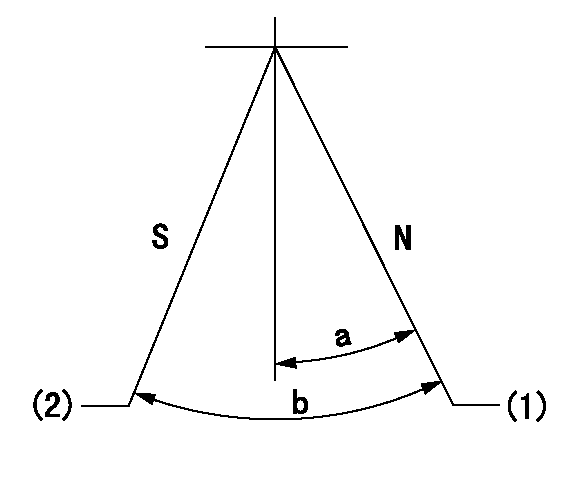

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=12deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=12deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

start by:a) remove turbocharger1. Put identification marks on the two housings and the cartridge assembly for use at assembly. 2. Remove two clamps (3) and make a separation of compressor housing (1) and turbine housing (2) from the cartridge assembly.

When the nut is loosened, do not put a side force on the shaft.

3. Put cartridge assembly (4) in position on tooling (A). Remove the nut from the shaft. 4. Use a press to push the shaft assembly out of the cartridge assembly. Remove compressor wheel (5). 5. Remove seal ring (8) and shroud (7) from shaft assembly (6). 6. Remove snap ring (9) with tool (B). 7. Use two screwdrivers to remove insert (10) from the cartridge housing. 8. Remove O-ring seal (12) from the insert.9. Remove sleeve (11) from the insert. Remove the seal ring from the sleeve. 10. Remove deflector (13) from the housing. 11. Remove bearing (14) from the cartridge housing. 12. Remove sleeve (15) and bearing (16) from the cartridge housing. 13. Remove ring (17). 14. Use tool (C) to remove snap ring (19), bearing (18) and snap ring (20) from the cartridge housing. 15. Turn the cartridge housing over. Use tool (C) to remove snap ring (22), bearing (21) and snap ring (23) from the housing.Assemble Turbocharger (Schwitzer 4MF)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Use tool (A) to install snap ring (2), bearing (3) and snap ring (1) in the housing. Install the snap rings with the round side toward the bearing. 3. Turn the housing over. Use tool (A) to install snap ring (5), bearing (6) and snap ring (4). Install the snap rings with the round side toward the bearing. 4. Put ring (7) in position in the housing. 5. Put bearing (8) in position. Make an alignment of the holes in the bearing with the dowels in the housing. Grooved side of the bearing must be up.6. Put sleeve (9) in position in the housing. 7. Put ring (10) in position on top of the bearing. 8. Install deflector (11) as shown. 9. Put seal ring (13) in position on sleeve (12). Install the sleeve in insert (15).10. Put O-ring seal (14) in position on the insert. 11. Put insert assembly (16) in position in the housing. 12. Use tool (B) to install snap ring (17) in the housing. 13. Put shaft assembly (18) in position on tooling (C).14. Put 6V2055 High Vacuum Grease in the seal ring groove on the shaft assembly.15. Install seal ring (19) on shaft assembly (18). 16. Put shroud (20) in position on the shaft assembly.17. Put cartridge housing (22) and compressor wheel (21) in position on the shaft assembly.

Do not put a side force on the shaft when the nut is tightened.

18. Put a small amount of oil on the face of the compressor wheel that will be under the nut. Install the nut and tighten it to a torque

When the nut is loosened, do not put a side force on the shaft.

3. Put cartridge assembly (4) in position on tooling (A). Remove the nut from the shaft. 4. Use a press to push the shaft assembly out of the cartridge assembly. Remove compressor wheel (5). 5. Remove seal ring (8) and shroud (7) from shaft assembly (6). 6. Remove snap ring (9) with tool (B). 7. Use two screwdrivers to remove insert (10) from the cartridge housing. 8. Remove O-ring seal (12) from the insert.9. Remove sleeve (11) from the insert. Remove the seal ring from the sleeve. 10. Remove deflector (13) from the housing. 11. Remove bearing (14) from the cartridge housing. 12. Remove sleeve (15) and bearing (16) from the cartridge housing. 13. Remove ring (17). 14. Use tool (C) to remove snap ring (19), bearing (18) and snap ring (20) from the cartridge housing. 15. Turn the cartridge housing over. Use tool (C) to remove snap ring (22), bearing (21) and snap ring (23) from the housing.Assemble Turbocharger (Schwitzer 4MF)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Use tool (A) to install snap ring (2), bearing (3) and snap ring (1) in the housing. Install the snap rings with the round side toward the bearing. 3. Turn the housing over. Use tool (A) to install snap ring (5), bearing (6) and snap ring (4). Install the snap rings with the round side toward the bearing. 4. Put ring (7) in position in the housing. 5. Put bearing (8) in position. Make an alignment of the holes in the bearing with the dowels in the housing. Grooved side of the bearing must be up.6. Put sleeve (9) in position in the housing. 7. Put ring (10) in position on top of the bearing. 8. Install deflector (11) as shown. 9. Put seal ring (13) in position on sleeve (12). Install the sleeve in insert (15).10. Put O-ring seal (14) in position on the insert. 11. Put insert assembly (16) in position in the housing. 12. Use tool (B) to install snap ring (17) in the housing. 13. Put shaft assembly (18) in position on tooling (C).14. Put 6V2055 High Vacuum Grease in the seal ring groove on the shaft assembly.15. Install seal ring (19) on shaft assembly (18). 16. Put shroud (20) in position on the shaft assembly.17. Put cartridge housing (22) and compressor wheel (21) in position on the shaft assembly.

Do not put a side force on the shaft when the nut is tightened.

18. Put a small amount of oil on the face of the compressor wheel that will be under the nut. Install the nut and tighten it to a torque

Have questions with 106671-0263?

Group cross 106671-0263 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-0263

9 400 616 656

1680196561

INJECTION-PUMP ASSEMBLY

PE6T

PE6T