Information injection-pump assembly

ZEXEL

106671-0245

1066710245

Rating:

Service parts 106671-0245 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/22.6(230)

15.

NOZZLE SET

Include in #1:

106671-0245

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-0245

1066710245

Zexel num

Bosch num

Firm num

Name

106671-0245

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R2(12.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

185.6

181.6

189.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.1

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

171

169

173

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.1

9.1

11.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

E

Rack position

R2(12.5)

+0.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

186.3

176.3

196.3

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.5

Boost pressure

kPa

4

2.7

4

Boost pressure

mmHg

30

20

30

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12+-0.2

Boost pressure

kPa

14.7

14.7

14.7

Boost pressure

mmHg

110

110

110

Boost compensator adjustment_03

Pump speed

r/min

300

300

300

Rack position

R2(12.5)

+0.2

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

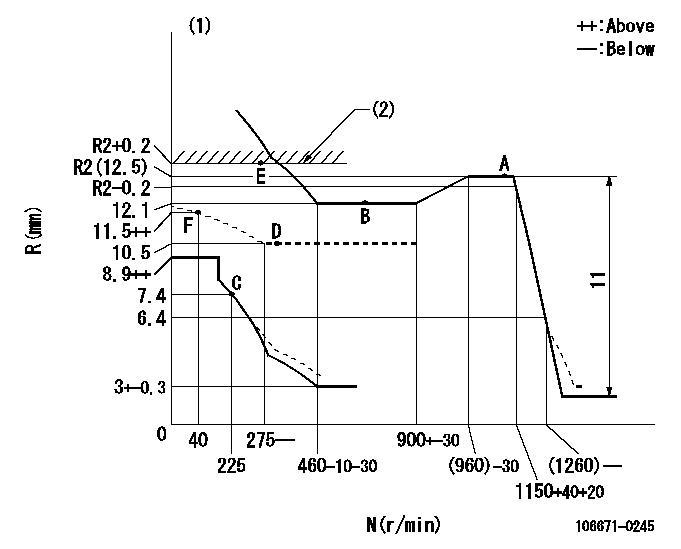

Test data Ex:

Governor adjustment

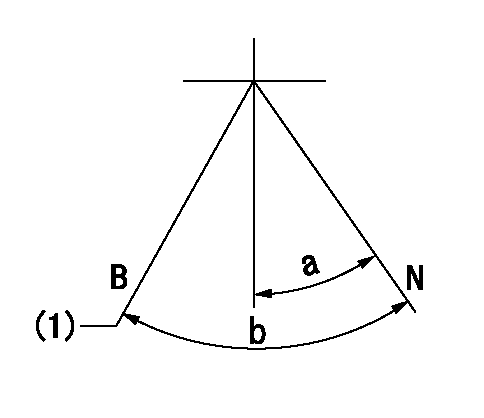

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Rack limit using stop lever

----------

DL=6.4-0.2mm

----------

----------

DL=6.4-0.2mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(6.5)deg t1=2--sec. t2=2--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=6.5+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(6.5)deg t1=2--sec. t2=2--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=6.5+-0.3deg R01=0/4load R02=4/4load

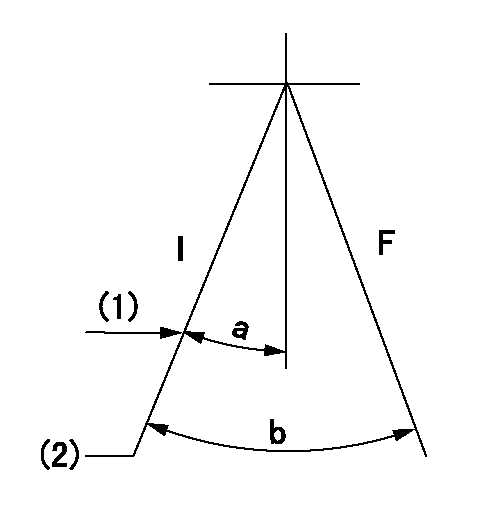

Speed control lever angle

F:Full speed

----------

----------

a=(31deg)+-5deg

----------

----------

a=(31deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)At center of threaded hole above R = aa

----------

aa=17mm

----------

a=22deg+-5deg b=33deg+-3deg

----------

aa=17mm

----------

a=22deg+-5deg b=33deg+-3deg

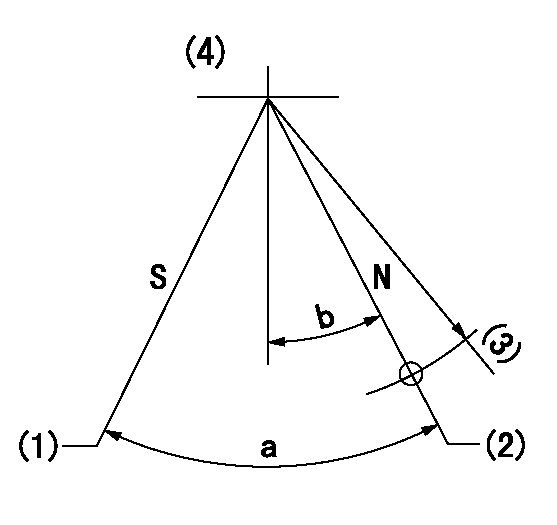

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)R = cc

(4)Adjust after setting excess fuel lever.

----------

aa=1+0.5mm bb=R2(12.5)+0.2mm cc=50mm

----------

a=32.5deg+-5deg b=30.5deg+-5deg

----------

aa=1+0.5mm bb=R2(12.5)+0.2mm cc=50mm

----------

a=32.5deg+-5deg b=30.5deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa

----------

aa=13mm

----------

a=(18deg) b=(32deg)

----------

aa=13mm

----------

a=(18deg) b=(32deg)

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1= 5+-0.02V V2f=0.3+0.03V V2i=2.2-0.03V

----------

----------

V1= 5+-0.02V V2f=0.3+0.03V V2i=2.2-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

There are two operation checks that are fast and need no special equipment. One check is the PULL-DOWN RPM CHECK to see if the BrakeSaver can give full braking force. The other check is the KLUNK CHECK to see if the valve spool in the BrakeSaver control valve has free movement. These two checks give an approximate indication that the BrakeSaver has the correct operation.Pull-Down RPM Check

The engine must give rated horsepower for this test to have accuracy.1. Actuate the brakes, put the transmission in NEUTRAL and operate the engine at high idle rpm (accelerator pedal all the way down).2. Make a record of the engine rpm.3. Put the BrakeSaver control to the full ON position.4. Make a record of the engine rpm with the BrakeSaver full on.5. The engine rpm with the BrakeSaver full on must be 150 25 rpm less than the engine rpm with the BrakeSaver off. If the difference in rpm is less than 125 rpm, the BrakeSaver is not giving full braking force. If the difference in rpm is more than 175 rpm, check the air pressure to the BrakeSaver control valve. The air pressure must not be more than 345 kPa (50 psi).

Do not run the engine at high idle rpm with the BrakeSaver ON for more than 15 seconds at a time. Let the engine run a low idle with the BrakeSaver off for five minutes to keep from getting the engine cooling system too hot.

Klunk Check (check for free movement of the valve spool)

1. Run the engine until the truck air system is at its maximum pressure and then stop the engine.2. Put the BrakeSaver in the full ON position before the air pressure in the truck air system gets below 480 kPa (70 psi).3. Put the BrakeSaver in the OFF position. A noise ("klunk") must be heard at the BrakeSaver control valve as the valve spool hits the cover at the air inlet end of the control valve.4. If the noise is not heard at the BrakeSaver control valve, remove and disassemble the control valve. Inspect the valve for: a. A damaged valve body.b. Damaged or worn springs in the valve spool.c. Damaged or worn valve spool.d. Damaged or worn O-ring seals or diaphragm in the control valve.e. Closed holes (small holes to feel pressure) in the side of the valve spool.For specific problems, make reference to the PROBLEM LIST below.Problem List

1. BrakeSaver does not give full braking force with the mode selector switch in the MANUAL position.2. BrakeSaver does not give full braking force with the mode selector switch in the AUTOMATIC-MANUAL position.3. BrakeSaver Oil temperature is too high.4. BrakeSaver does not turn OFF or become empty.5. Oil leakage from the flywheel housing.6. Oil leakage from the clutch housing or transmission.

Gauge Holes For Troubleshooting

(1) Oil pressure from the BrakeSaver. (2) Oil pressure from the engine. (3) Oil pressure to the BrakeSaver. (4) Test point for BrakeSaver oil temperature. (5) Oil pressure to the engine. (6) Air pressure

The engine must give rated horsepower for this test to have accuracy.1. Actuate the brakes, put the transmission in NEUTRAL and operate the engine at high idle rpm (accelerator pedal all the way down).2. Make a record of the engine rpm.3. Put the BrakeSaver control to the full ON position.4. Make a record of the engine rpm with the BrakeSaver full on.5. The engine rpm with the BrakeSaver full on must be 150 25 rpm less than the engine rpm with the BrakeSaver off. If the difference in rpm is less than 125 rpm, the BrakeSaver is not giving full braking force. If the difference in rpm is more than 175 rpm, check the air pressure to the BrakeSaver control valve. The air pressure must not be more than 345 kPa (50 psi).

Do not run the engine at high idle rpm with the BrakeSaver ON for more than 15 seconds at a time. Let the engine run a low idle with the BrakeSaver off for five minutes to keep from getting the engine cooling system too hot.

Klunk Check (check for free movement of the valve spool)

1. Run the engine until the truck air system is at its maximum pressure and then stop the engine.2. Put the BrakeSaver in the full ON position before the air pressure in the truck air system gets below 480 kPa (70 psi).3. Put the BrakeSaver in the OFF position. A noise ("klunk") must be heard at the BrakeSaver control valve as the valve spool hits the cover at the air inlet end of the control valve.4. If the noise is not heard at the BrakeSaver control valve, remove and disassemble the control valve. Inspect the valve for: a. A damaged valve body.b. Damaged or worn springs in the valve spool.c. Damaged or worn valve spool.d. Damaged or worn O-ring seals or diaphragm in the control valve.e. Closed holes (small holes to feel pressure) in the side of the valve spool.For specific problems, make reference to the PROBLEM LIST below.Problem List

1. BrakeSaver does not give full braking force with the mode selector switch in the MANUAL position.2. BrakeSaver does not give full braking force with the mode selector switch in the AUTOMATIC-MANUAL position.3. BrakeSaver Oil temperature is too high.4. BrakeSaver does not turn OFF or become empty.5. Oil leakage from the flywheel housing.6. Oil leakage from the clutch housing or transmission.

Gauge Holes For Troubleshooting

(1) Oil pressure from the BrakeSaver. (2) Oil pressure from the engine. (3) Oil pressure to the BrakeSaver. (4) Test point for BrakeSaver oil temperature. (5) Oil pressure to the engine. (6) Air pressure

Have questions with 106671-0245?

Group cross 106671-0245 ZEXEL

Nissan-Diesel

106671-0245

INJECTION-PUMP ASSEMBLY