Information injection-pump assembly

ZEXEL

106671-0212

1066710212

Rating:

Service parts 106671-0212 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96514

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

15.

NOZZLE SET

Include in #1:

106671-0212

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-0212

1066710212

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R2(11.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

153.8

149.8

157.8

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

161.7

159.7

163.7

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.1

9.1

11.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1(10.7)

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

120.6

118.6

122.6

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

12.3

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

171.1

166.1

176.1

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R1(10.7)

Boost pressure

kPa

4

Boost pressure

mmHg

30

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12.3

Boost pressure

kPa

17.3

17.3

17.3

Boost pressure

mmHg

130

130

130

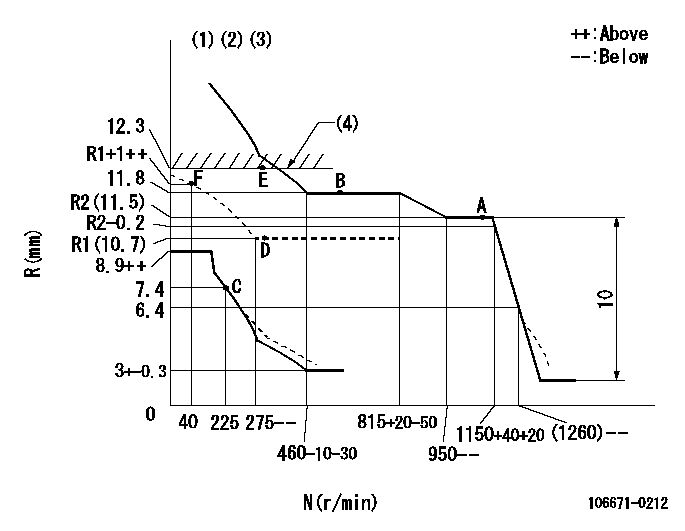

Test data Ex:

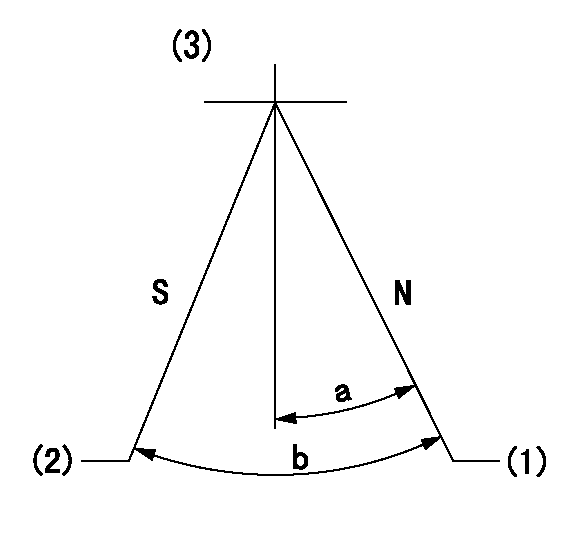

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Damper spring setting: DL

(4)Rack limit using stop lever

----------

RT=1 TH=2mm DL=6.4-0.2mm

----------

----------

RT=1 TH=2mm DL=6.4-0.2mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(6.5)deg t1=2--sec. t2=2--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=6.5+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(6.5)deg t1=2--sec. t2=2--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=6.5+-0.3deg R01=0/4load R02=4/4load

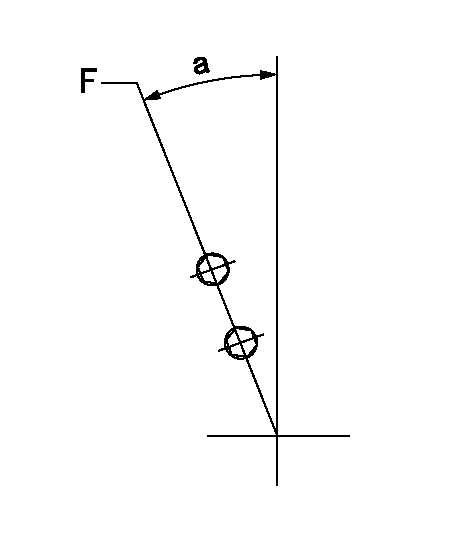

Speed control lever angle

F:Full speed

----------

----------

a=31deg+-5deg

----------

----------

a=31deg+-5deg

0000000901

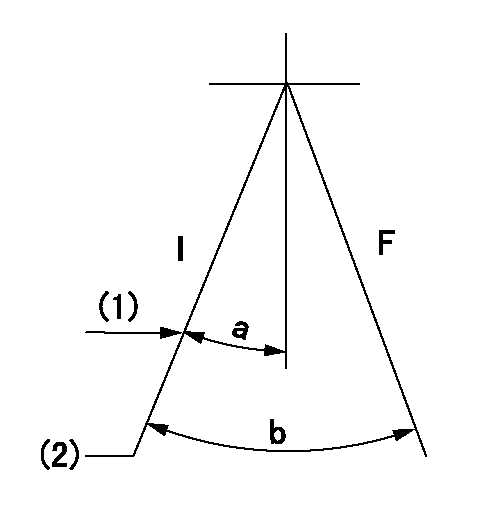

F:Full load

I:Idle

(1)Stopper bolt setting

(2)At center of threaded hole above R = aa

----------

aa=17mm

----------

a=22deg+-5deg b=32.5deg+-3deg

----------

aa=17mm

----------

a=22deg+-5deg b=32.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Adjust after setting excess fuel lever.

----------

aa=12.3mm bb=1+0.5mm

----------

a=29.5deg+-5deg b=31.5deg+-5deg

----------

aa=12.3mm bb=1+0.5mm

----------

a=29.5deg+-5deg b=31.5deg+-5deg

0000001101

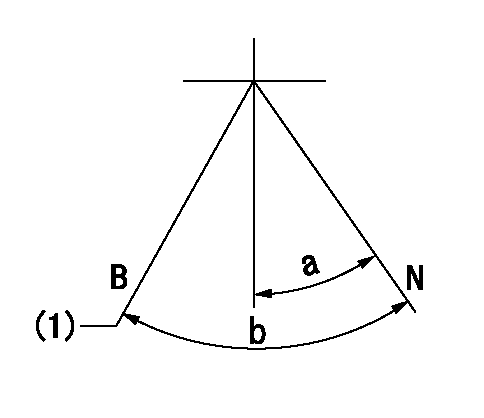

N:Normal

B:When boosted

(1)Rack position = aa

----------

aa=13mm

----------

a=(18deg) b=(32deg)

----------

aa=13mm

----------

a=(18deg) b=(32deg)

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1= 5+-0.02V V2f=0.3+0.03V V2i=2.2-0.03V

----------

----------

V1= 5+-0.02V V2f=0.3+0.03V V2i=2.2-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

March 8, 2005

(Revised July 2005)

U-76

A-57

O-65

TT-3

Afterfailure only PRODUCT SUPPORT PROGRAM FOR INSTALLINGINJECTOR SLEEVE KITS IN CERTAIN C11 AND C13 TRUCK ENGINES

1713 PS50933

This Program can only be administeredafter a failure occurs. The decision whether to apply the Program is madeby the dealer. When reporting the repair, use "PS50933" as the Part numberand "7755" as the Group Number. Use "96" as the Warranty Claim DescriptionCode and use "Z" as the SIMS Description Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe March 8, 2005 Service Letter. Changes have been made to the ServiceClaim Allowance.TERMINATION DATE

March 31, 2007PROBLEM

This letter will address the repair proceduresand inspection guidelines for fuel in coolant failures in certain C11 andC13 ACERT engines.AFFECTED PRODUCT

Model Identification Number

C11 KCA1-2365

C13 KCB1-14118PARTS NEEDED

Qty

Part Number

Description

1 2638162 INJECTOR KITACTION REQUIRED

If a failure of an injector sleeve isdiscovered replace all 6 injector sleeves. Follow special instruction REHS2410,field installation of the 263-8162 injector sleeve kit. After the repairof the injector sleeves is completed, inspect the following components:pre-cooler hoses, coolant diverter valve, and thermostat(s). Replace anycomponents that show signs of deformity or swelling due to exposure tofuel.SERVICE CLAIM ALLOWANCES

SMCS Code Description SC MC CV CO

1240-030 Test 0.5 0.5 0.5 0.5

1240-074 Wash 0.3 0.3 0.3 0.3

1100-035 Troubleshoot 1.0 1.0 1.0 1.0

1290-010-S Remove and Install Unit Injector,Set (all) 5.2 5.0 5.0 5.1

1713-010-S Remove and Install Unit InjectorSleeve, Set (all) 2.0 2.0 2.0 2.0

1350-046-ES Flush Engine Cooling System 1.3 1.3 1.3 1.3

Note: If equippedwith a head-mounted radiator bracket, claim code (1353-010-BK).

Note: If R&I ofair cleaner housing is required, claim code (1051-010).PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

(Revised July 2005)

U-76

A-57

O-65

TT-3

Afterfailure only PRODUCT SUPPORT PROGRAM FOR INSTALLINGINJECTOR SLEEVE KITS IN CERTAIN C11 AND C13 TRUCK ENGINES

1713 PS50933

This Program can only be administeredafter a failure occurs. The decision whether to apply the Program is madeby the dealer. When reporting the repair, use "PS50933" as the Part numberand "7755" as the Group Number. Use "96" as the Warranty Claim DescriptionCode and use "Z" as the SIMS Description Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe March 8, 2005 Service Letter. Changes have been made to the ServiceClaim Allowance.TERMINATION DATE

March 31, 2007PROBLEM

This letter will address the repair proceduresand inspection guidelines for fuel in coolant failures in certain C11 andC13 ACERT engines.AFFECTED PRODUCT

Model Identification Number

C11 KCA1-2365

C13 KCB1-14118PARTS NEEDED

Qty

Part Number

Description

1 2638162 INJECTOR KITACTION REQUIRED

If a failure of an injector sleeve isdiscovered replace all 6 injector sleeves. Follow special instruction REHS2410,field installation of the 263-8162 injector sleeve kit. After the repairof the injector sleeves is completed, inspect the following components:pre-cooler hoses, coolant diverter valve, and thermostat(s). Replace anycomponents that show signs of deformity or swelling due to exposure tofuel.SERVICE CLAIM ALLOWANCES

SMCS Code Description SC MC CV CO

1240-030 Test 0.5 0.5 0.5 0.5

1240-074 Wash 0.3 0.3 0.3 0.3

1100-035 Troubleshoot 1.0 1.0 1.0 1.0

1290-010-S Remove and Install Unit Injector,Set (all) 5.2 5.0 5.0 5.1

1713-010-S Remove and Install Unit InjectorSleeve, Set (all) 2.0 2.0 2.0 2.0

1350-046-ES Flush Engine Cooling System 1.3 1.3 1.3 1.3

Note: If equippedwith a head-mounted radiator bracket, claim code (1353-010-BK).

Note: If R&I ofair cleaner housing is required, claim code (1051-010).PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.