Information injection-pump assembly

BOSCH

9 400 616 647

9400616647

ZEXEL

106662-4250

1066624250

DAIHATSU

M000200070Z

m000200070z

Rating:

Service parts 106662-4250 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

M126410160ZZ

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Include in #1:

106662-4250

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 647

9400616647

ZEXEL

106662-4250

1066624250

DAIHATSU

M000200070Z

m000200070z

Zexel num

Bosch num

Firm num

Name

106662-4250

9 400 616 647

M000200070Z DAIHATSU

INJECTION-PUMP ASSEMBLY

M2SP K

M2SP K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105780-0030

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.05

2

2.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

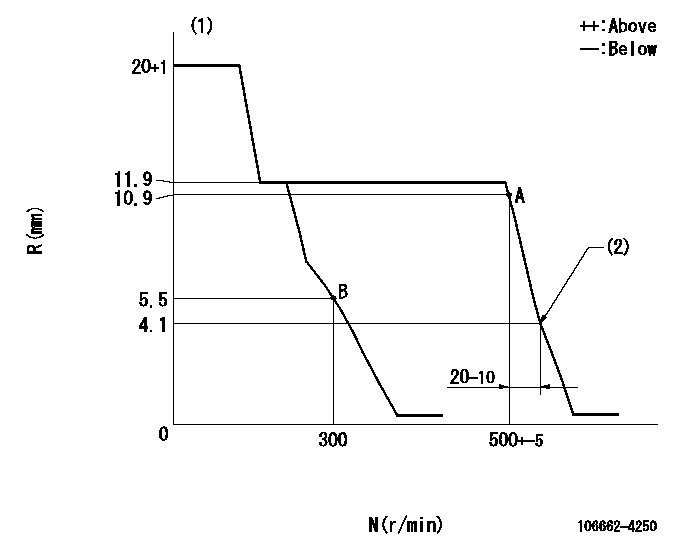

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

176

170.7

181.3

Difference in delivery

mm3/st.

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

25

22.5

27.5

Difference in delivery

mm3/st.

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=9 L1=4.1-0.5mm

----------

----------

K=9 L1=4.1-0.5mm

----------

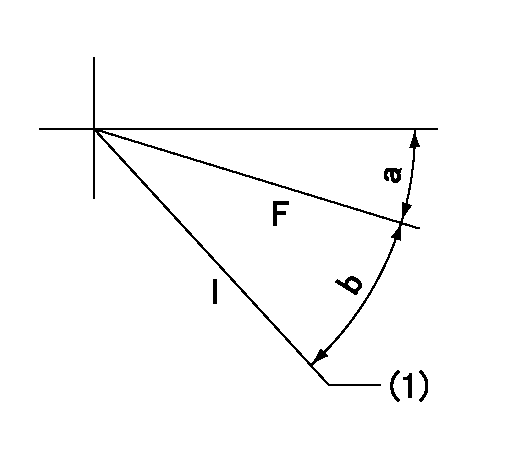

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=9deg+-5deg

----------

----------

a=17deg+-5deg b=9deg+-5deg

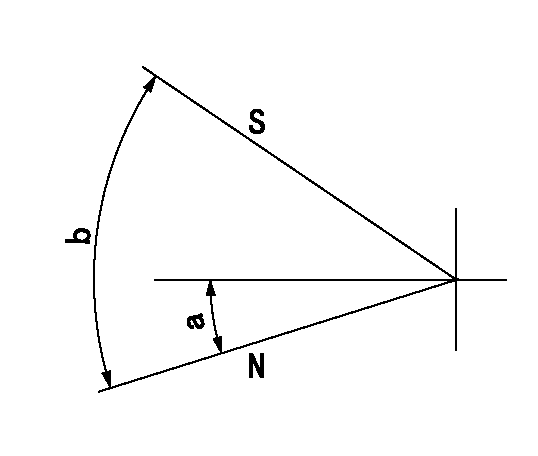

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=11deg+-5deg b=53deg+-5deg

----------

----------

a=11deg+-5deg b=53deg+-5deg

Information:

Problem

The lift adjusting screw may break in certain 7E3969 1W5829, 4W8483, and 7W3710 Fuel Injection Nozzles with date codes of A9 thru M9, and A0 thru L0. If the adjusting screw breaks the adjustment screw in the nozzle can vibrate toward the fuel shutoff position which can result in the following symptoms:

A) Low Horsepower. The affected engine may not reach rated rpm. The engine does not emit any excessive black smoke. The engine may or may not have a detectable miss.B) Low Horsepower. The affected engine may not reach the rated rpm. The engine may emit heavy black smoke.C) Low Idle Misfire. Some engines run at rated speed but have a miss when idling.Affected Product

Model & Identification Number

3208 (30A3876-4565; 90N72172-73198; 75V10138-10420; 62W58913-Up; 01Z19535-22859; 03Z9391-10398; 51Z79496-80434)

Parts Needed

8* - 7E3969 Nozzle8* - 9L6969 Nozzle8* - 9N3299 Nozzle8* - 1W5829 Nozzle8* - 4W1819 Nozzle8* - 4W8483 Nozzle8* - 7W3710 Nozzle*Refer to your engine arrangement for the correct part number.Action Required

Parts Stock

Inspect all 7E3969, 9L6969, 9N3299, 1W5829, 4W1819, 4W8483, and 7W3710, Fuel Injection Nozzles for the date code as shown in the illustration. If date codes of A9, B9, C9, D9, E9, F9, G9, H9, I9, J9, K9, L9, M9, A0, B0, C0, D0, E0, F0, G0, H0, I0, J0, K0, or L0 are on the nozzles, remove the nozzles from parts stock.

Fuel Injection Nozzle Date Codes If the part number or date code is difficult to read, apply white paint to the area and carefully remove any excess.

Affected Product

If possible, isolate the cylinder(s) with a failed nozzle by loosening the fuel line nuts. The nozzle cap(s) may be removed to check for a broken lift adjustment screw.

Check the date code on the replacement nozzles before installing them. The date code on the flat of the nozzle nut must be M0, A1, B1, C1, or higher. Some nozzles will have a date code above the part number and a second date code on another flat of the nozzle nut. The second date code will continue two letters and a number. The first letter will always be an "R". The second letter is for the month "A-M". The number will be 0 for 1990 or 1 for 1991.

Any nozzle with a date code between A9 and M9 or A0 and L0 without the second date code should not be used.

On a twin engine marine installation, install new nozzles in both engines.

Service Claim Allowances

Parts Stock

Submit one claim for all 7E3969, 9L6969, 9N3299, 1W5829, 4W1819, 4W8483, and 7W3710, Fuel Injection Nozzles removed from parts stock.

Affected Product

This is a 5-hour job.

On a twin engine marine installation, a separate claim must be filed for the second engine.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

The lift adjusting screw may break in certain 7E3969 1W5829, 4W8483, and 7W3710 Fuel Injection Nozzles with date codes of A9 thru M9, and A0 thru L0. If the adjusting screw breaks the adjustment screw in the nozzle can vibrate toward the fuel shutoff position which can result in the following symptoms:

A) Low Horsepower. The affected engine may not reach rated rpm. The engine does not emit any excessive black smoke. The engine may or may not have a detectable miss.B) Low Horsepower. The affected engine may not reach the rated rpm. The engine may emit heavy black smoke.C) Low Idle Misfire. Some engines run at rated speed but have a miss when idling.Affected Product

Model & Identification Number

3208 (30A3876-4565; 90N72172-73198; 75V10138-10420; 62W58913-Up; 01Z19535-22859; 03Z9391-10398; 51Z79496-80434)

Parts Needed

8* - 7E3969 Nozzle8* - 9L6969 Nozzle8* - 9N3299 Nozzle8* - 1W5829 Nozzle8* - 4W1819 Nozzle8* - 4W8483 Nozzle8* - 7W3710 Nozzle*Refer to your engine arrangement for the correct part number.Action Required

Parts Stock

Inspect all 7E3969, 9L6969, 9N3299, 1W5829, 4W1819, 4W8483, and 7W3710, Fuel Injection Nozzles for the date code as shown in the illustration. If date codes of A9, B9, C9, D9, E9, F9, G9, H9, I9, J9, K9, L9, M9, A0, B0, C0, D0, E0, F0, G0, H0, I0, J0, K0, or L0 are on the nozzles, remove the nozzles from parts stock.

Fuel Injection Nozzle Date Codes If the part number or date code is difficult to read, apply white paint to the area and carefully remove any excess.

Affected Product

If possible, isolate the cylinder(s) with a failed nozzle by loosening the fuel line nuts. The nozzle cap(s) may be removed to check for a broken lift adjustment screw.

Check the date code on the replacement nozzles before installing them. The date code on the flat of the nozzle nut must be M0, A1, B1, C1, or higher. Some nozzles will have a date code above the part number and a second date code on another flat of the nozzle nut. The second date code will continue two letters and a number. The first letter will always be an "R". The second letter is for the month "A-M". The number will be 0 for 1990 or 1 for 1991.

Any nozzle with a date code between A9 and M9 or A0 and L0 without the second date code should not be used.

On a twin engine marine installation, install new nozzles in both engines.

Service Claim Allowances

Parts Stock

Submit one claim for all 7E3969, 9L6969, 9N3299, 1W5829, 4W1819, 4W8483, and 7W3710, Fuel Injection Nozzles removed from parts stock.

Affected Product

This is a 5-hour job.

On a twin engine marine installation, a separate claim must be filed for the second engine.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 106662-4250?

Group cross 106662-4250 ZEXEL

Daihatsu

Yanmar

Yanmar

Daihatsu

106662-4250

9 400 616 647

M000200070Z

INJECTION-PUMP ASSEMBLY

M2SP

M2SP