Information injection-pump assembly

BOSCH

9 400 616 646

9400616646

ZEXEL

106662-4200

1066624200

DAIHATSU

M121610210Z

m121610210z

Rating:

Service parts 106662-4200 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

M126410160ZZ

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Include in #1:

106662-4200

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 646

9400616646

ZEXEL

106662-4200

1066624200

DAIHATSU

M121610210Z

m121610210z

Zexel num

Bosch num

Firm num

Name

106662-4200

9 400 616 646

M121610210Z DAIHATSU

INJECTION-PUMP ASSEMBLY

M2SP K 14CA INJECTION PUMP ASSY PE6P,6PD PE

M2SP K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

157

157

Overflow valve opening pressure

kgf/cm2

1.6

1.6

1.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.05

2

2.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

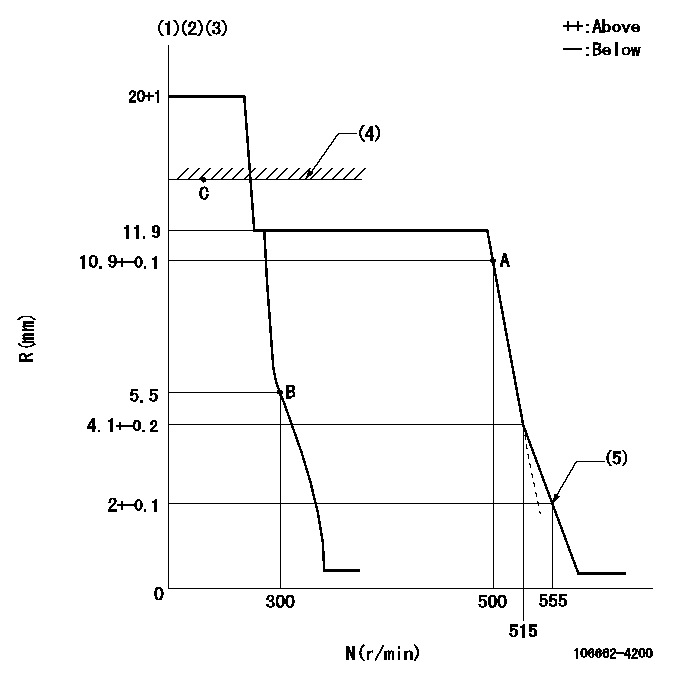

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

176

170.7

181.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

25

22.5

27.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Delivered with idle spring not operating.

(4)RACK LIMIT: RAL

(5)Set idle sub-spring

----------

K=9 RAL=11.9+0.5mm

----------

----------

K=9 RAL=11.9+0.5mm

----------

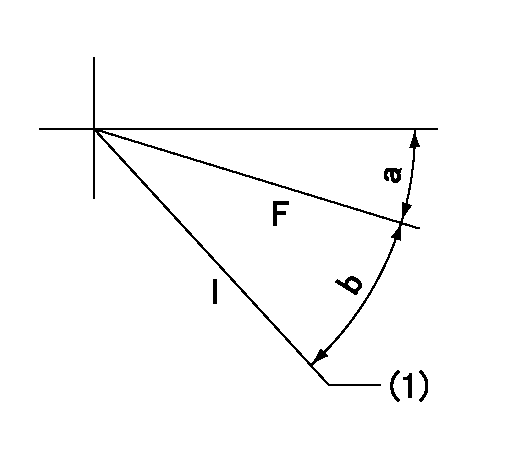

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=9deg+-5deg

----------

----------

a=17deg+-5deg b=9deg+-5deg

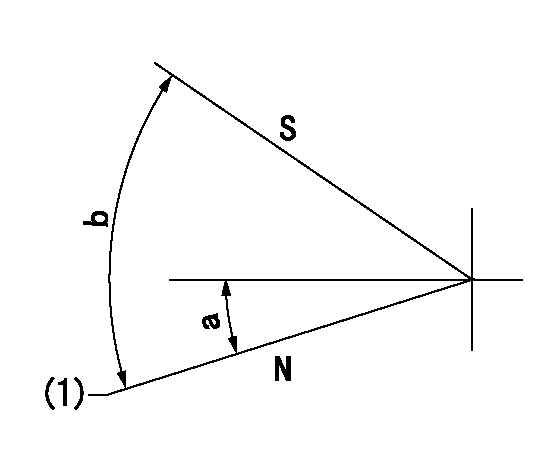

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=11deg+-5deg b=53deg+-5deg

----------

----------

a=11deg+-5deg b=53deg+-5deg

Information:

Caterpillar: Confidential Yellow

PARTS STOCK ACTION ONLY - CERTAIN 7000 SERIES FUEL INJECTION NOZZLES NEED TO BE REMOVED FROM PARTS STOCK - PI7210 - MAILED US AND CANADA, CACO, COFA, BRAZIL, CFEL, COSA, TRUCK TEPS

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-105 A-76 AU-71 B-16 E-49 O-69 TT-4 PARTS STOCK ACTION NEEDED 1254 PI7210 Termination Date

August 31, 1989

Problem

Certain 7000 Series fuel injection nozzles may crack and loose their nozzle tips if there is a small indentation or dent in the nozzle between the tip end and the carbon dam.

Action Required

Inspect the following nozzles in parts stock for any small indentations or dents in the tip of the nozzle between the carbon dam groove and the tip end of the nozzle. Remove all nozzles from parts stock that have indentations or dents that are deep enough to be felt with a thumbnail. See the illustration. 8N7003 4W7015 7W7023 8N7005 4W7016 7W7024 8N7006 4W7017 7W7026 4W7018 7W7030 4W7019 7W7031 4W7020 7W7032 4W7021

PARTS STOCK ACTION ONLY - CERTAIN 7000 SERIES FUEL INJECTION NOZZLES NEED TO BE REMOVED FROM PARTS STOCK - PI7210 - MAILED US AND CANADA, CACO, COFA, BRAZIL, CFEL, COSA, TRUCK TEPS

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-105 A-76 AU-71 B-16 E-49 O-69 TT-4 PARTS STOCK ACTION NEEDED 1254 PI7210 Termination Date

August 31, 1989

Problem

Certain 7000 Series fuel injection nozzles may crack and loose their nozzle tips if there is a small indentation or dent in the nozzle between the tip end and the carbon dam.

Action Required

Inspect the following nozzles in parts stock for any small indentations or dents in the tip of the nozzle between the carbon dam groove and the tip end of the nozzle. Remove all nozzles from parts stock that have indentations or dents that are deep enough to be felt with a thumbnail. See the illustration. 8N7003 4W7015 7W7023 8N7005 4W7016 7W7024 8N7006 4W7017 7W7026 4W7018 7W7030 4W7019 7W7031 4W7020 7W7032 4W7021

Have questions with 106662-4200?

Group cross 106662-4200 ZEXEL

Daihatsu

106662-4200

9 400 616 646

M121610210Z

INJECTION-PUMP ASSEMBLY

M2SP

M2SP