Information injection-pump assembly

BOSCH

9 400 616 643

9400616643

ZEXEL

106662-4160

1066624160

DAIHATSU

M121610140A

m121610140a

Rating:

Cross reference number

BOSCH

9 400 616 643

9400616643

ZEXEL

106662-4160

1066624160

DAIHATSU

M121610140A

m121610140a

Zexel num

Bosch num

Firm num

Name

106662-4160

9 400 616 643

M121610140A DAIHATSU

INJECTION-PUMP ASSEMBLY

M2 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

M2 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

157

157

Overflow valve opening pressure

kgf/cm2

1.6

1.6

1.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.05

2

2.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

175

170.2

179.8

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

25

22.5

27.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

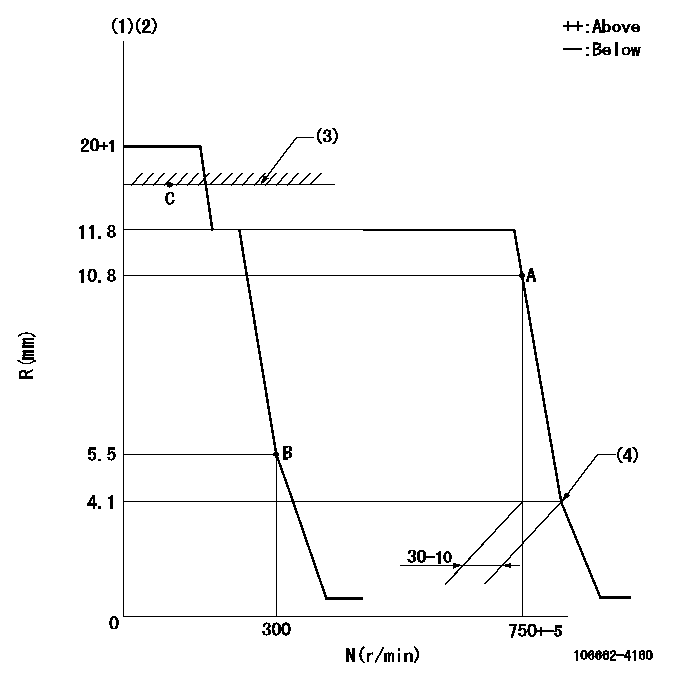

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Delivered with idle spring not operating.

(3)RACK LIMIT: RAL

(4)Idle sub spring setting: L1.

----------

K=9 RAL=14+-0.5mm L1=4.1-0.5mm

----------

----------

K=9 RAL=14+-0.5mm L1=4.1-0.5mm

----------

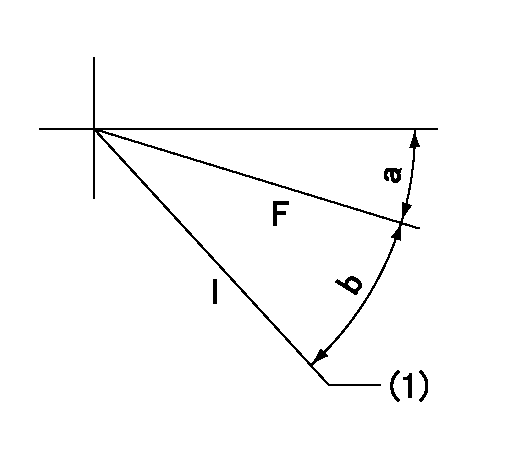

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=21.5deg+-5deg

----------

----------

a=3deg+-5deg b=21.5deg+-5deg

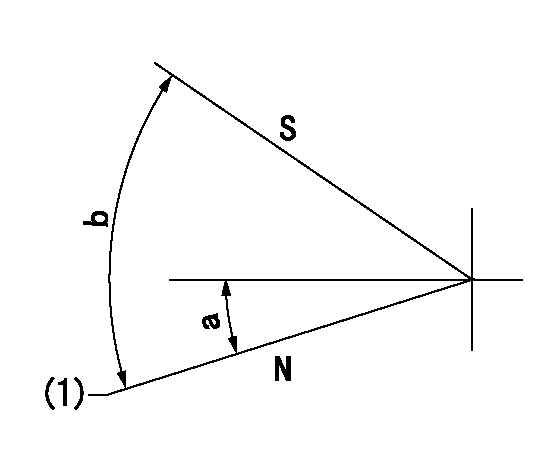

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=(11deg) b=(53deg)

----------

----------

a=(11deg) b=(53deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR THE USE OF TWO CLAMPS TO HOLD THE BODY AND FUEL NOZZLE IN POSITION ON 3406, 3408 AND 3412 ENGINES - MAILED WORLDWIDE EXC EPT CANADA, BRAZIL & CACO

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

PRODUCT SUPPORT PROGRAM FOR THE USE OF TWO CLAMPS TO HOLD THE BODY AND FUEL NOZZLE IN POSITION ON 3406, 3408 AND 3412 ENGINES, 1252, PS4019 U-74 AU-59 E-47 O-45 TT-12 TA-6 TM-6 This Program can be administered either before or after a failure. In either case the warranty allowances will be the same and contingent damage will not be allowed. The decision whether to apply the Program is made by the dealer. When reporting the repair use "PS4019" as Part Number and "7755" as Group Number. Although products in the field are to be administered as described above, dealers should rework parts stock immediately. Termination Date

September 30, 1986.

Problem

Engines equipped with 4W5719 (3406) or 4W5733 (3408, 3412) Adapter Assemblies use one 4W5717 Clamp to hold the body and fuel nozzle in position. See the Illustration. These adapter assemblies are also used in 0R0977 (3406) 0R0980 (3408) and 0R2659 (3412) Remanufactured Head Assemblies. One clamp does not provide enough force to hold the body and fuel nozzle tight. This permits fuel to leak past the internal parts of the nozzle and cause the nozzle case to bulge or split. This program provides for an additional clamp and bolts to be used with these adapter assemblies. (SEE ILLUSTRATION)

Affected Product

1/850907/01/002

Parts Needed

1-4W5717 Clamp and 2-5P6900 Bolts for each adapter assembly.

Action Required

The new parts should be installed on cylinder heads in parts stock immediately. Only cylinder heads received before this Service Letter need to be checked. The new parts should be installed on products in the field only when the valve cover has been removed for some other repair or inspection. Install the new clamp and bolts 180 deg. from the existing clamp and bolts. Tighten the bolts for the new clamp to 31 +/- 7 N X m (23 +/- 5 lb ft). Check to make sure the bolts for the existing clamp are tightened to the same torque. Then check the torque on the bolts for the new clamp. (SEE ILLUSTRATION)

Parts Disposition

Not applicable.

PSP FOR THE USE OF TWO CLAMPS TO HOLD THE BODY AND FUEL NOZZLE IN POSITION ON 3406, 3408 AND 3412 ENGINES - MAILED WORLDWIDE EXC EPT CANADA, BRAZIL & CACO

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

PRODUCT SUPPORT PROGRAM FOR THE USE OF TWO CLAMPS TO HOLD THE BODY AND FUEL NOZZLE IN POSITION ON 3406, 3408 AND 3412 ENGINES, 1252, PS4019 U-74 AU-59 E-47 O-45 TT-12 TA-6 TM-6 This Program can be administered either before or after a failure. In either case the warranty allowances will be the same and contingent damage will not be allowed. The decision whether to apply the Program is made by the dealer. When reporting the repair use "PS4019" as Part Number and "7755" as Group Number. Although products in the field are to be administered as described above, dealers should rework parts stock immediately. Termination Date

September 30, 1986.

Problem

Engines equipped with 4W5719 (3406) or 4W5733 (3408, 3412) Adapter Assemblies use one 4W5717 Clamp to hold the body and fuel nozzle in position. See the Illustration. These adapter assemblies are also used in 0R0977 (3406) 0R0980 (3408) and 0R2659 (3412) Remanufactured Head Assemblies. One clamp does not provide enough force to hold the body and fuel nozzle tight. This permits fuel to leak past the internal parts of the nozzle and cause the nozzle case to bulge or split. This program provides for an additional clamp and bolts to be used with these adapter assemblies. (SEE ILLUSTRATION)

Affected Product

1/850907/01/002

Parts Needed

1-4W5717 Clamp and 2-5P6900 Bolts for each adapter assembly.

Action Required

The new parts should be installed on cylinder heads in parts stock immediately. Only cylinder heads received before this Service Letter need to be checked. The new parts should be installed on products in the field only when the valve cover has been removed for some other repair or inspection. Install the new clamp and bolts 180 deg. from the existing clamp and bolts. Tighten the bolts for the new clamp to 31 +/- 7 N X m (23 +/- 5 lb ft). Check to make sure the bolts for the existing clamp are tightened to the same torque. Then check the torque on the bolts for the new clamp. (SEE ILLUSTRATION)

Parts Disposition

Not applicable.

Have questions with 106662-4160?

Group cross 106662-4160 ZEXEL

Daihatsu

Yanmar

Yanmar

Daihatsu

106662-4160

9 400 616 643

M121610140A

INJECTION-PUMP ASSEMBLY

M2

M2