Information injection-pump assembly

ZEXEL

106661-5511

1066615511

Rating:

Service parts 106661-5511 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96502

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106661-5511

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106661-5511

1066615511

Zexel num

Bosch num

Firm num

Name

106661-5511

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

153.3

150.3

156.3

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

153.6

150.6

156.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

149.6

147.6

151.6

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_04

Adjusting point

D

Rack position

11.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

145.5

142.5

148.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_05

Adjusting point

E

Rack position

10.3

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

109.5

103.5

115.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

F

Rack position

6.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11

10

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.3

Boost pressure

kPa

33.3

33.3

33.3

Boost pressure

mmHg

250

250

250

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

10.9

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Boost compensator adjustment_03

Pump speed

r/min

300

300

300

Rack position

11.5

Boost pressure

kPa

53.3

53.3

53.3

Boost pressure

mmHg

400

400

400

Timer adjustment

Pump speed

r/min

700

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

0.5

0.1

0.9

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

1.7

1.3

2.1

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

3

2.6

3.4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Rack limit using stop lever

(5)Damper spring setting

(6)Variable speed specification: idling adjustment

(7)Main spring setting

----------

RT=1 TH=2mm

----------

----------

RT=1 TH=2mm

----------

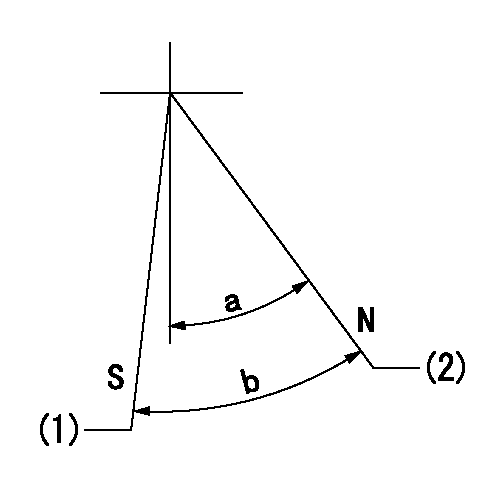

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+4deg-3deg b=22deg+-4deg

----------

----------

a=11deg+4deg-3deg b=22deg+-4deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=32.5deg+-5deg b=42.5deg+-3deg

----------

----------

a=32.5deg+-5deg b=42.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa (non-injection rack position)

(2)Rack position bb

----------

aa=1.9-0.5mm bb=11.5mm

----------

a=27.5deg+-5deg b=28deg+-3deg

----------

aa=1.9-0.5mm bb=11.5mm

----------

a=27.5deg+-5deg b=28deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

2. Disconnect the fuel injection lines (2) from pump housing. Put plugs or caps in all lines and openings.3. Remove the three bolts that hold the fuel filter (3) to the aftercooler housing.4. Disconnect the sensing line (1) for the fuel ratio control from the aftercooler housing. 5. Disconnect the oil supply line (4) from the turbocharger.6. Remove the two water lines (5). 7. Disconnect the water outlet line (6) for the air compressor from the cylinder head.8. Remove the bolts (7) that fasten the cylinder head to the cylinder block. 9. Install 3/8"-16NC forged eyebolts in the cylinder head. Fasten a hoist and remove the cylinder head assembly. Weight of cylinder head assembly is 575 lb. (260 kg). Be sure to install a new gasket between the spacer plate and the cylinder block before installing the cylinder head assembly. See REMOVE and INSTALL SPACER PLATE in DISASSEMBLY AND ASSEMBLY.Install Cylinder Head Assembly

1. Clean the top surface of spacer plate and the surface it is in contact with on the cylinder head.2. Install the cylinder head gasket, water seals, and gasket on timing gear cover. 3. Install the 3/8"-16NC forged eyebolts in the cylinder head. Fasten a hoist and put the cylinder head assembly into position on the engine. Make sure the gear (1) in cylinder head is engaged with drive gear (2). 4. Put 9M3710 Anti-Seize Compound on the threads of the bolts for cylinder head. Install the bolts and washers. Tighten the bolts as follows: 1 -Tighten all bolts in number order to 135 lb.ft. (18.7 mkg).2 -Tighten all bolts in number order to 185 5 lb.ft. (25.6 0.7 mkg).3 -Tighten all bolts using hand torque only to 185 5 lb.ft. (25.6 0.7 mkg). 5. Install the two water lines (4).6. Connect the oil supply line (3) to the turbocharger.7. Connect the water outlet line (5) for the air compressor to the cylinder head. 8. Connect the sensing line (6) for the fuel ratio control to the aftercooler housing.9. Put the fuel filter in position, and install the three bolts.10. Remove the plugs and fuel injection lines and pumps. Connect the fuel injection lines (7) to the pumps. Tighten the nuts on fuel lines to 30 5 lb.ft. (4.1 0.7 mkg).11. Fill the cooling system with coolant.end by: a) install camshaft housingb) install fan drive

1. Clean the top surface of spacer plate and the surface it is in contact with on the cylinder head.2. Install the cylinder head gasket, water seals, and gasket on timing gear cover. 3. Install the 3/8"-16NC forged eyebolts in the cylinder head. Fasten a hoist and put the cylinder head assembly into position on the engine. Make sure the gear (1) in cylinder head is engaged with drive gear (2). 4. Put 9M3710 Anti-Seize Compound on the threads of the bolts for cylinder head. Install the bolts and washers. Tighten the bolts as follows: 1 -Tighten all bolts in number order to 135 lb.ft. (18.7 mkg).2 -Tighten all bolts in number order to 185 5 lb.ft. (25.6 0.7 mkg).3 -Tighten all bolts using hand torque only to 185 5 lb.ft. (25.6 0.7 mkg). 5. Install the two water lines (4).6. Connect the oil supply line (3) to the turbocharger.7. Connect the water outlet line (5) for the air compressor to the cylinder head. 8. Connect the sensing line (6) for the fuel ratio control to the aftercooler housing.9. Put the fuel filter in position, and install the three bolts.10. Remove the plugs and fuel injection lines and pumps. Connect the fuel injection lines (7) to the pumps. Tighten the nuts on fuel lines to 30 5 lb.ft. (4.1 0.7 mkg).11. Fill the cooling system with coolant.end by: a) install camshaft housingb) install fan drive

Have questions with 106661-5511?

Group cross 106661-5511 ZEXEL

Nissan-Diesel

106661-5511

INJECTION-PUMP ASSEMBLY