Information injection-pump assembly

BOSCH

9 400 616 622

9400616622

ZEXEL

106661-5422

1066615422

NISSAN-DIESEL

1671396806

1671396806

Rating:

Service parts 106661-5422 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660096508

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Include in #1:

106661-5422

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 622

9400616622

ZEXEL

106661-5422

1066615422

NISSAN-DIESEL

1671396806

1671396806

Zexel num

Bosch num

Firm num

Name

106661-5422

9 400 616 622

1671396806 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PE6 * K

PE6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.2

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

122.3

120.3

124.3

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7+-0.5

Pump speed

r/min

240

240

240

Average injection quantity

mm3/st.

10

8.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

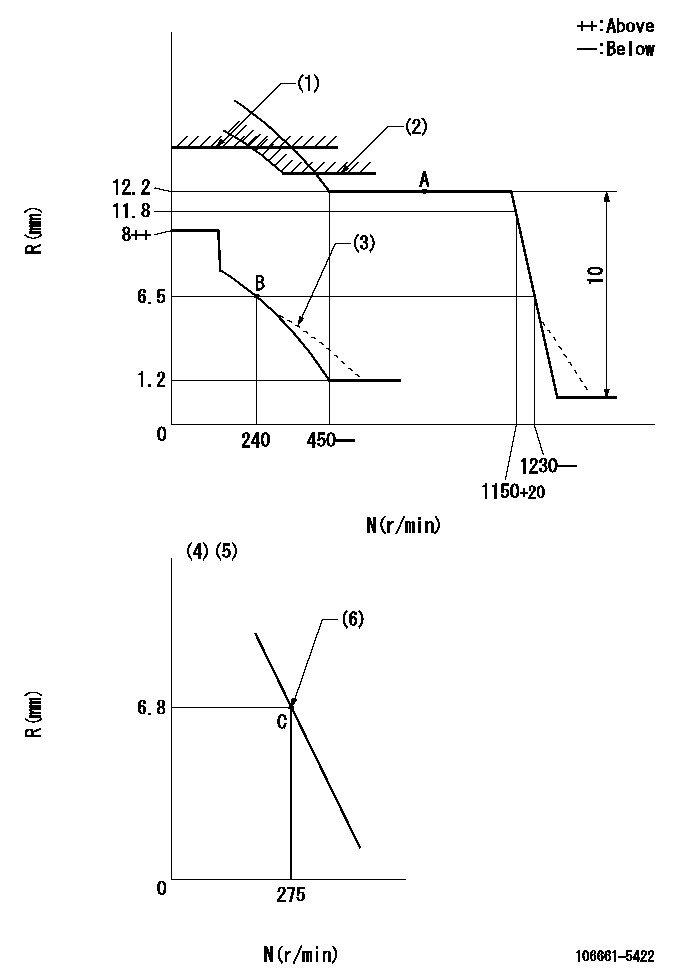

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack limit using the stop lever: R1

(2)Excess fuel setting for starting: SXL

(3)Damper spring setting: DL

(4)Variable speed specification: idling adjustment

(5)Fix the lever at the full-load position at delivery.

(6)Main spring setting

----------

R1=14+-0.1mm SXL=12.2+0.2mm DL=5.5-0.5mm

----------

----------

R1=14+-0.1mm SXL=12.2+0.2mm DL=5.5-0.5mm

----------

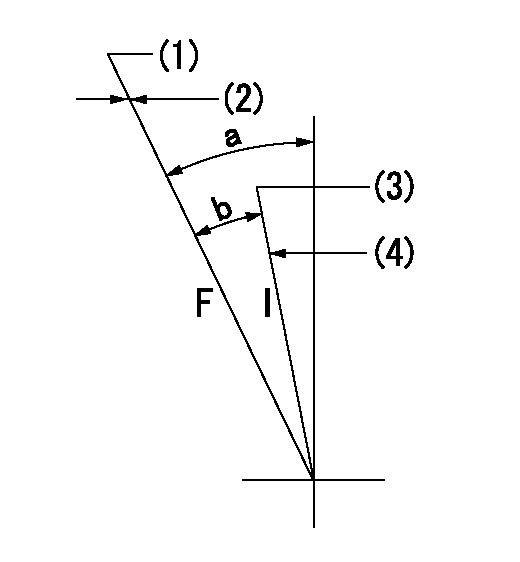

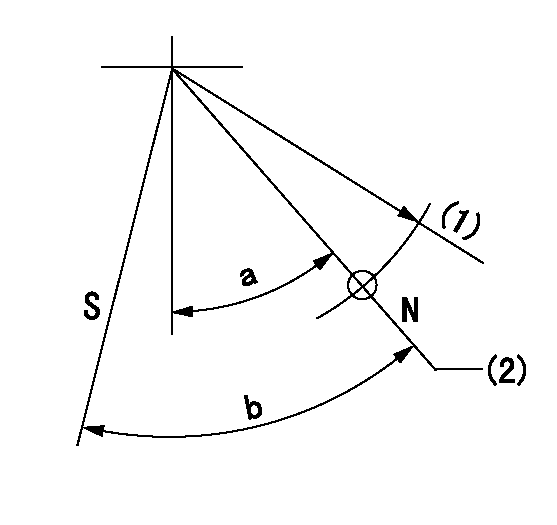

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Set the stopper bolt (fixed at full-load position at delivery.)

(3)Set the pump speed at bb.

(4)Stopper bolt setting

----------

aa=1150r/min bb=275r/min

----------

a=31deg+-5deg b=23deg+-5deg

----------

aa=1150r/min bb=275r/min

----------

a=31deg+-5deg b=23deg+-5deg

0000000901

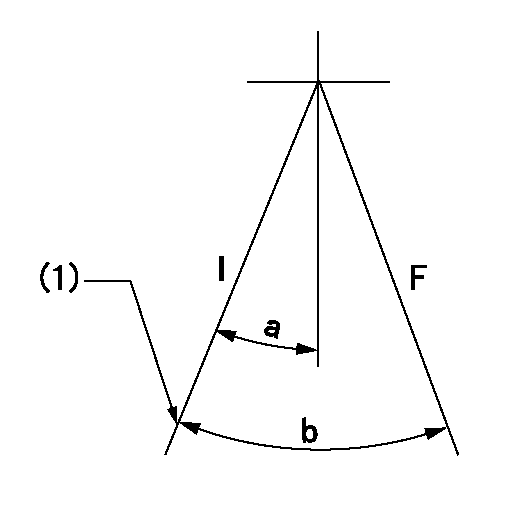

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=15deg+-5deg b=40.5deg+-3deg

----------

----------

a=15deg+-5deg b=40.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)R = aa

(2)Rack position bb

----------

aa=50mm bb=14+-0.1mm

----------

a=34.5deg+-5deg b=36.5deg+-3deg

----------

aa=50mm bb=14+-0.1mm

----------

a=34.5deg+-5deg b=36.5deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

CompactorCB68B (S/N: 496100-100)Asphalt PaverAP1055F (S/N: RLM1-105)AP555F (S/N: 5F51-101)AP600F (S/N: LR61-108)AP655F (S/N: 4801-103; P651-124; ML61-113; 4791-122,125-125)Excavator320D2 (S/N: BW21-235; CY21-192; ZBH1-975,10001-10185)323D2 (S/N: FLC1-219,10001-10004; KCE1-428; JEG1-257; PJP1-1331; YCR1-288; TDT1-560,10001-10135; KBX1-191,10001-10006)326D2 (S/N: REC1-197,199-199,202-203,205-206,208-212; MZH1-282,10001-10006; JFL1-174; XAM1-510,10001-10060; MGW1-313; NBX1-156; KGY1-323)329D2 (S/N: RGA1-309; KJB1-180; SHJ1-190; TMJ1-376; WDT145-145; THW1-506,509-554)330D2 (S/N: PTE1-211; ZBF1-514,10001-10073,10076-10088; RCK1-357; SZK1-561,10001-10143)Generator SetXQP150 (S/N: PJ71-105,107-107,109-112)Motor Grader120L (S/N: E93100-100)120N (S/N: E94100-100; E951-101)Soil Compactor815K (S/N: WCS100-100,201-201)TelehandlerTL1055D (S/N: MNT63-63,150-181,183-186,188-188,192-192)TL1255D (S/N: MYW1-157,160-161,15700-15700)Track-Type TractorD3K2 (S/N: FT31-103,2100-2115,2119-2119; LT31-113,2110-2111)D4K2 (S/N: RT3130-130,2130-2130)D5K2 (S/N: WT31-157,2140-2174; YT31-157,2150-2163,2167-2167)D5R2 (S/N: R5A150-150,152-158,161-162)D6K2 (S/N: MXK1-273; RPR1-307)D6N (S/N: P5T1-166)Vibratory Soil CompactorCS79B (S/N: CM71-101)Wheel Loader924K (S/N: KW41-395; ENC1-1566; HJF1-101,250-818; SNZ100-100,250-430)930K (S/N: DYB1-486; EYE1-127,250-789; FRK1-131,350-433; P3K1-195; TNY1-69)938K (S/N: W8K1-306; REP150-150,450-625; XXT1-137,350-962; HFW1-932)950 GC (S/N: M5K1-1212,1214-1233)950L (S/N: LXX1-228)950M (S/N: ENE1-212,215-234; LCR201-201)962L (S/N: MTN1-163; SXS1-203)962M (S/N: LSE1-208)Wheel Skidder525D (S/N: 2L51-153)535D (S/N: 3L51-136)545D (S/N: 4L51-159)555D (S/N: 5L51-111)Wheeled ExcavatorM315D2 (S/N: CA41-103,189-266)M317D2 (S/N: CA61-284)M320D2 (S/N: EN81-330; CH91-149)M322D 2 MH (S/N: EN9215-215)M322D2 (S/N: EN21-207)M324D 2 MH (S/N: EN31-179)Description Of Change: A new injector sleeve has been introduced. The new injector sleeve has improved sealing bead geometry.Adaptable To: New 517-8243 Injector Sleeve replaces 277-5067 Injector Sleeve.To remove the existing injector sleeve, refer to Disassembly and Assembly, Fuel Injection Lines - Remove for the correct procedure.To install the new injector sleeve, refer to Disassembly and Assembly, Fuel Injection Lines - Install for the correct procedure.

Have questions with 106661-5422?

Group cross 106661-5422 ZEXEL

Nissan-Diesel

Nissan-Diesel

106661-5422

9 400 616 622

1671396806

INJECTION-PUMP ASSEMBLY

PE6

PE6