Information injection-pump assembly

ZEXEL

106661-5250

1066615250

Rating:

Service parts 106661-5250 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96003

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106661-5250

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106661-5250

1066615250

Zexel num

Bosch num

Firm num

Name

106661-5250

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

138

137

139

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.6

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

114.5

113

116

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

6.2+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

17.1

16

18.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.75

0.4

1.1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.25

0.9

1.6

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

2.5

2.5

2.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

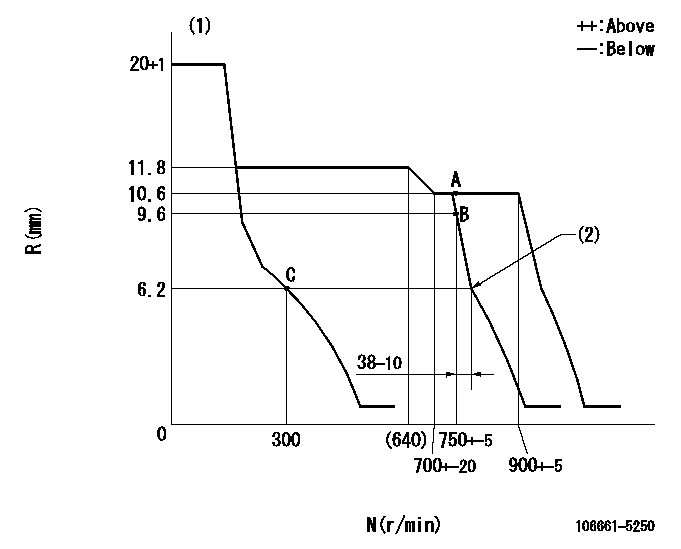

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=18 L1=6.2-0.5mm

----------

----------

K=18 L1=6.2-0.5mm

----------

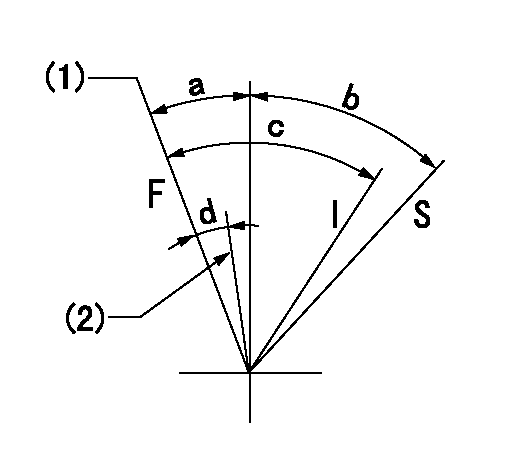

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Speed set at aa (setting at shipping)

(2)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=32deg+-3deg c=25deg+-5deg d=8deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=32deg+-3deg c=25deg+-5deg d=8deg+-5deg

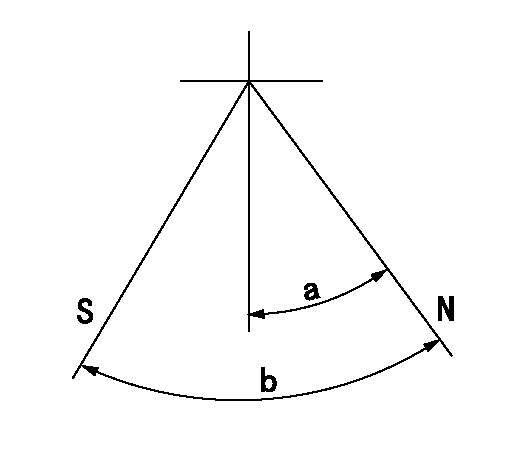

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

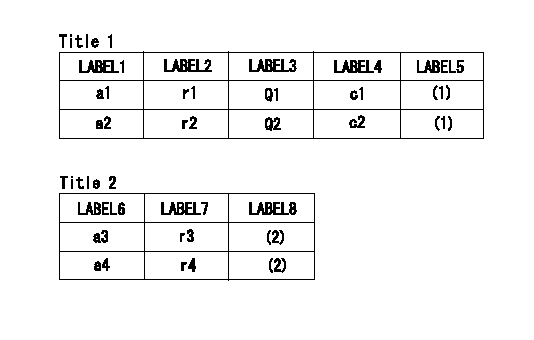

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=E r1=750r/min r2=750r/min Q1=138+-1mm3/st Q2=154+-1mm3/st c1=+-2.5% c2=+-2.5% a3=18 a4=15 r3=900r/min r4=750r/min

----------

----------

a1=A a2=E r1=750r/min r2=750r/min Q1=138+-1mm3/st Q2=154+-1mm3/st c1=+-2.5% c2=+-2.5% a3=18 a4=15 r3=900r/min r4=750r/min

Information:

AFFECTED PRODUCT

Model Identification Number

C9 MTB00101-00106, 109-190, 197-199, 1000-1001, 1003-1005, 1007-1221, 1227-1387, 1396-1429, 1431-1464, 1467-1550, 1553-2020

PARTS NEEDED

Qty

Part Number Description

6 1093207 SEAL-O-RING

12 1482903 SEAL-O-RING

6 1495240 RING-BACKUP

6 2271200 SLEEVE-INJECTOR

6 2930730 RING-BACKUP

6 3107255 SEAL-O-RING

6 3107257 SEAL-O-RING

ACTION REQUIRED

Follow Special Instruction REHS3798 for proper installation of injector sleeve o-rings.

Injector o-rings need to be replaced when the injector is removed to perform sleeve o-ring replacement. Reference SEBD6792 for correct orientation of injector o-rings.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 9.6-hour job

*Dealer to perform most economical repair*

Description_____________SMCS Code_________Hours

Wash____________________1290-074__________0.3

R&I Injectors___________1290-010-S________4.2

Remove Sleeve___________1713-011__________1.3

Clean Sleeve Bore_______1713-70-BO________0.8

Install sleeve seals____1713-012-SA_______0.8

Install Sleeve set______1713-012-S________1.7

Test After______________1290-030__________0.5

*Exception may be considered and claimed depending on chassis type*

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REPLACING INJECTOR SLEEVE O-RINGS ON CERTAIN C9 MTB ON-HIGHWAY TRUCK ENGINES

MODELS INVOLVED - C9 Mass Transit Bus Engines

Dear Caterpillar Product Owner:

The injector sleeve o-rings need to be replaced on certain C9 MTB On-Highway truck engines. The existing o-rings can cause fuel to enter the coolant system if failure occurs. You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 20Sep2007 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 20Sep2007 Service Letter

Have questions with 106661-5250?

Group cross 106661-5250 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106661-5250

INJECTION-PUMP ASSEMBLY