Information injection-pump assembly

ZEXEL

106661-4041

1066614041

YANMAR

12769151010

12769151010

Rating:

Service parts 106661-4041 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106661-4041

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106661-4041

1066614041

YANMAR

12769151010

12769151010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

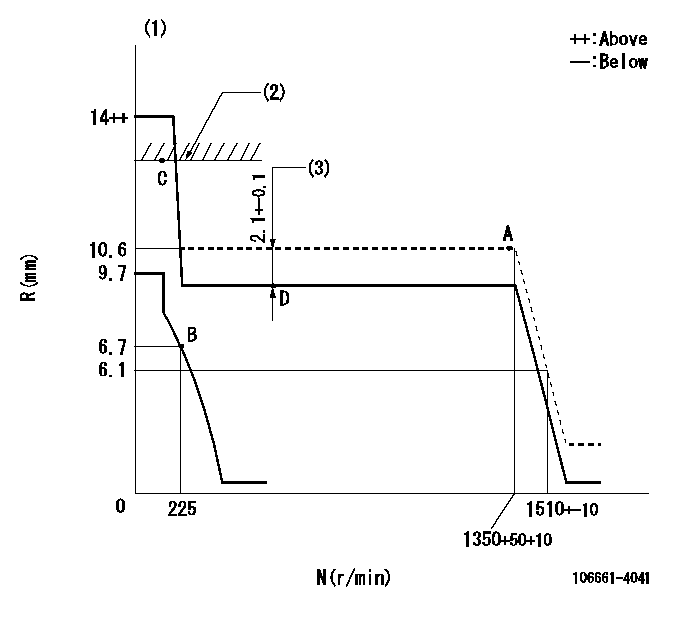

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1350

1350

1350

Each cylinder's injection qty

mm3/st.

182

178.4

185.6

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

27.8

24.3

31.3

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

214

209

219

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-2.1

Boost pressure

kPa

13.3

10.6

16

Boost pressure

mmHg

100

80

120

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.6)

Boost pressure

kPa

46.7

40

53.4

Boost pressure

mmHg

350

300

400

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Boost compensator stroke

----------

K=14

----------

----------

K=14

----------

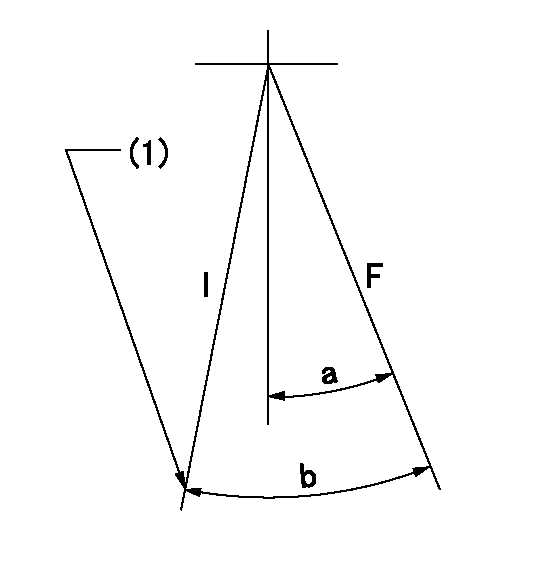

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=30deg+-5deg

----------

----------

a=17deg+-5deg b=30deg+-5deg

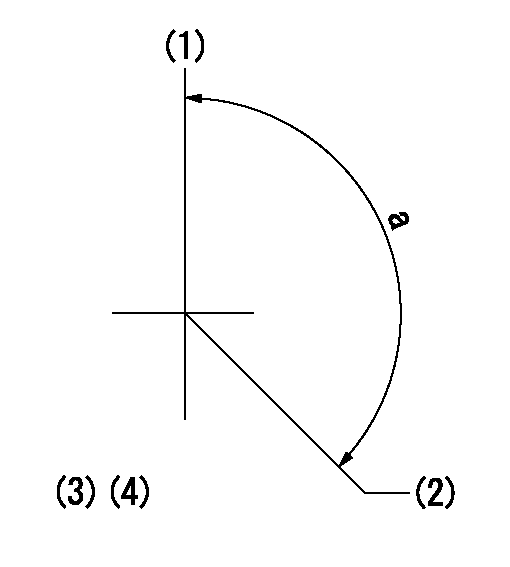

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=25deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.2mm

----------

a=25deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(120deg)

----------

----------

a=(120deg)

Information:

3406B and 3406C Non-Peec Engines

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil