Information injection-pump assembly

BOSCH

F 019 Z10 623

f019z10623

ZEXEL

106661-4040

1066614040

Rating:

Service parts 106661-4040 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106661-4040

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 623

f019z10623

ZEXEL

106661-4040

1066614040

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

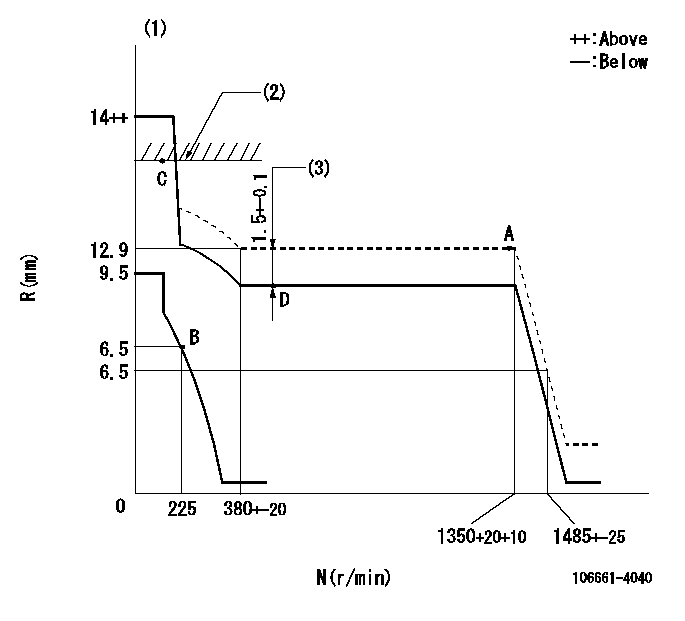

Injection quantity adjustment

Adjusting point

A

Rack position

12.9

Pump speed

r/min

1350

1350

1350

Each cylinder's injection qty

mm3/st.

155

151.9

158.1

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.5+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.8

16.3

21.3

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

11.4

Boost pressure

kPa

13.3

10.6

16

Boost pressure

mmHg

100

80

120

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

12.9

Boost pressure

kPa

37.3

30.6

44

Boost pressure

mmHg

280

230

330

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Boost compensator stroke

----------

K=12 RAL=13.1+0.2mm

----------

----------

K=12 RAL=13.1+0.2mm

----------

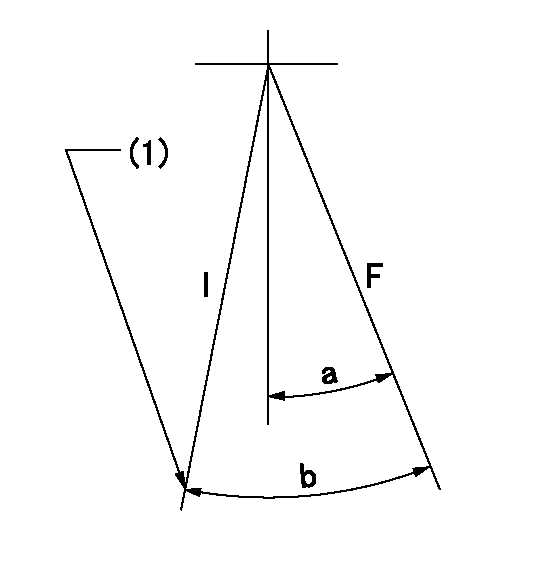

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=30deg+-5deg

----------

----------

a=12deg+-5deg b=30deg+-5deg

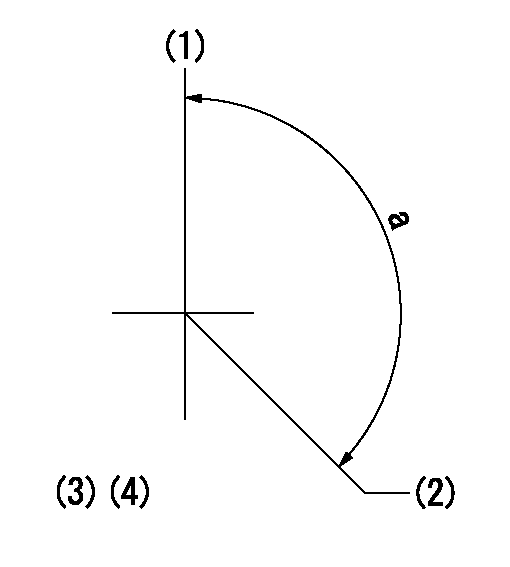

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=25deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.2mm

----------

a=25deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(120deg)

----------

----------

a=(120deg)

Information:

Parts Required For 4C-8180 Timing Tool Group

Refer to Chart A for item identification.Assemble and Set the 4C-8180 Timing Tool Group

1. Obtain a 108-2104 Plunger and Barrel Assembly. This part can be new or used. If the part is used, make sure it is in good working condition. The plunger should move freely in the barrel.

4C-8181 Timing Tool Assembly

(9) 8J-3819 Spring. (10) 1N-3257 Retainer Ring. (11) Plunger and barrel from 108-2104 Plunger and Barrel Assembly. (12) 4C-8178 Indicator Mount Bonnet. (14) 4C-8179 Bonnet Nut. (16) 2W-3429 Gear Segment (part of 108-2104). (17) 8N-0669 Bolt (part of 108-2104). (18) 4P-8704 Spring (part of 108-2104). (19) 9Y-2088 Washer.2. Make a 4C-8181 Timing Tool Assembly out of the 108-2104 Plunger and Barrel Assembly. The 4C-8181 Timing Tool Assembly is not a serviceable part. a. Remove and discard 8N-0669 Bolt (17), 2W-3429 Gear Segment (16), and 4P-8704 Spring (18) from the 108-2104 Plunger and Barrel Assembly.b. Assemble 8J-3819 Spring (9) and 9Y-2088 Washer (19) onto plunger. The 9Y-2088 Washer is part of the 108-2104 Plunger and Barrel Assembly.c. Install the 4C-8178 Indicator Mount Bonnet (12) onto the barrel using a 1N-3257 Retainer Ring (10).d. Slip 4C-8179 Bonnet Nut (14) over indicator mount bonnet (12).e. This tool is now a 4C-8181 Timing Tool Assembly (11).3. Assemble knurled gauge collar (3) onto gauge (5) by threading them together. Hand tighten the two parts. Make sure the gauging surfaces are clean and free of all debris, nicks, etc.4. Install 4C-8181 Timing Tool Assembly (11) into gauge collar (3).5. Thread bonnet nut (14) into gauge collar (3) and hand tighten with 9U-5120 Spanner Wrench (13). This will secure timing tool assembly (11) into gauge collar (3).6. Spring (9) on the timing tool assembly should make the end of the plunger extend approximately 30 mm (1.2 in) past the end of gauge (5).7. Push on the end of the plunger and make sure it travels freely (under spring force) in and out of the gauge block bore. If there is binding, disassemble and correct the problem.8. Install either a 5P-4814 Collet (6) or 4C-2982 Collet Assembly (7) into indicator mount bonnet (12).9. Install an indicator with a 5P-7262 Contact Point into collet (6 or 7). Use either a 6V-6106 Dial Indicator or an 8T-1002 Probe connected to an 8T-1001 Electronic Position Indicator.

Do not over tighten collet (6 or 7) holding the indicator. Over-tightening can result in damage to the indicator or the electronic position indicator probe.

10. Tighten collet (6 or 7) just enough to make sure the indicator or electronic position indicator probe will not move in collet.11. Zero the indicator by following this procedure. a. Place the 4C-8183 Gauge Plate (8) onto a flat surface.b. Carefully hold the entire 4C-8180 Timing Tool Group and place it on the gauge plate, with the end of the plunger contacting the plate.c. Push down on the entire assembly, compressing the spring, until the bottom of gauge (5) is in complete contact with gauge plate (8).

Zero The Timing Tool Assembly With