Information injection-pump assembly

BOSCH

9 400 616 602

9400616602

ZEXEL

106661-4000

1066614000

DAIHATSU

M121610010A

m121610010a

Rating:

Service parts 106661-4000 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

M126410160ZZ

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Include in #1:

106661-4000

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 602

9400616602

ZEXEL

106661-4000

1066614000

DAIHATSU

M121610010A

m121610010a

Zexel num

Bosch num

Firm num

Name

106661-4000

9 400 616 602

M121610010A DAIHATSU

INJECTION-PUMP ASSEMBLY

M2 K

M2 K

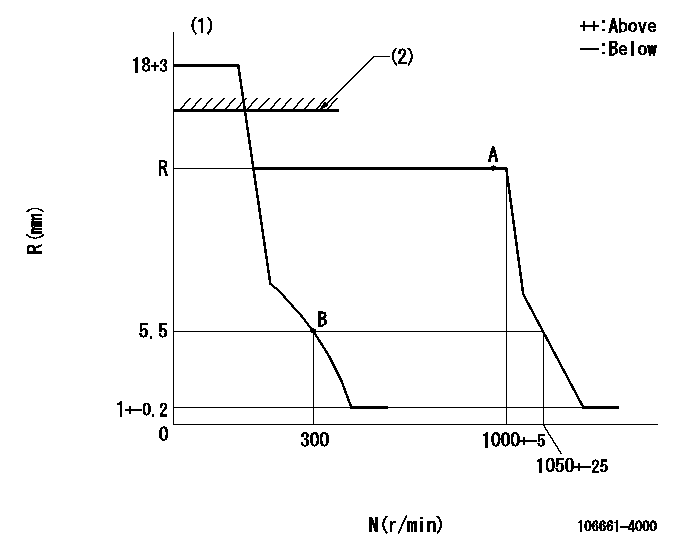

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105780-0030

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.05

2

2.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R(10)

Pump speed

r/min

930

930

930

Average injection quantity

mm3/st.

157

152.2

161.8

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

25

22.5

27.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

2

1.5

2.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=10 RAL=14+-0.5mm

----------

----------

K=10 RAL=14+-0.5mm

----------

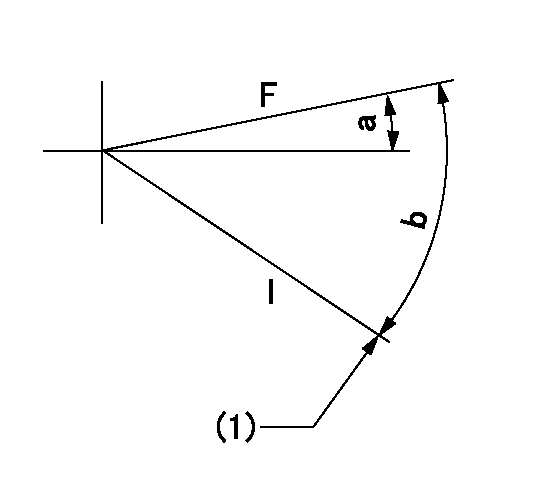

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=4deg+-5deg b=27deg+-5deg

----------

----------

a=4deg+-5deg b=27deg+-5deg

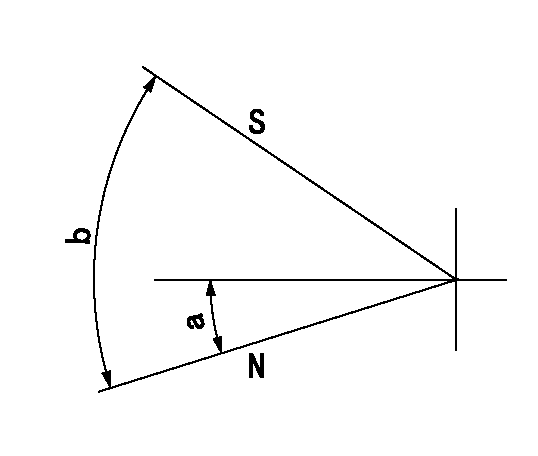

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(11deg) b=(53deg)

----------

----------

a=(11deg) b=(53deg)

Information:

Outside Leaks

Leaks in Hoses or Connections ... Check all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps.Leaks in the Radiator and/or Expansion Tank ... Put pressure to the radiator and/or expansion tank with a cooling system pressurizing pump and check for leaks.Leaks in the Heater ... Put pressure to the cooling system with a cooling system pressurizing pump and check the heater for leaks.Leaks in the Water Pump ... Check the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, install a new water pump.Cylinder Head Gasket Leakage ... Look for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.Coolant Leaks At The Overflow Tube

Defective Pressure Cap ... Check the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap with a cooling system pressurizing pump.Engine Runs Too Hot ... If coolant temperature is too high, pressure will be high enough to lift the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Above Normal Heating" in COOLING SYSTEM chart.Expansion Tank Too Small or Installed Wrong ... The expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly and is according to the recommendations of the truck manufacturer.Cylinder Head Gasket Leakage, or Crack(s) in Cylinder Head or Cylinder Block ... Remove the radiator cap and with the engine running look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. With the engine not running, check each cylinder with the cylinder leakage tester. If you see air bubbles in the coolant during this test, there is a leak of combustion gas into the cooling system. Remove the cylinder heads from the engine. Check cylinder heads, cylinder walls and head gasket surface of cylinder block for cracks. When installing heads, use new head gaskets. *Inside Leakage

Cylinder Head Gasket Leakage ... If the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.Crack(s) in Cylinder Head ... Crack(s) in the upper surface of the cylinder head or an area between a water passage and an opening into the crankcase can allow coolant to get into the crankcase.Crack(s) in Cylinder Block ... Crack(s) in the cylinder block between a water passage and the crankcase will let coolant get into the crankcase.*Authorized dealers are equipped with the necessary tools and personnel familiar with disassembly and assembly procedures

Leaks in Hoses or Connections ... Check all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps.Leaks in the Radiator and/or Expansion Tank ... Put pressure to the radiator and/or expansion tank with a cooling system pressurizing pump and check for leaks.Leaks in the Heater ... Put pressure to the cooling system with a cooling system pressurizing pump and check the heater for leaks.Leaks in the Water Pump ... Check the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, install a new water pump.Cylinder Head Gasket Leakage ... Look for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.Coolant Leaks At The Overflow Tube

Defective Pressure Cap ... Check the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap with a cooling system pressurizing pump.Engine Runs Too Hot ... If coolant temperature is too high, pressure will be high enough to lift the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Above Normal Heating" in COOLING SYSTEM chart.Expansion Tank Too Small or Installed Wrong ... The expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly and is according to the recommendations of the truck manufacturer.Cylinder Head Gasket Leakage, or Crack(s) in Cylinder Head or Cylinder Block ... Remove the radiator cap and with the engine running look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. With the engine not running, check each cylinder with the cylinder leakage tester. If you see air bubbles in the coolant during this test, there is a leak of combustion gas into the cooling system. Remove the cylinder heads from the engine. Check cylinder heads, cylinder walls and head gasket surface of cylinder block for cracks. When installing heads, use new head gaskets. *Inside Leakage

Cylinder Head Gasket Leakage ... If the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.Crack(s) in Cylinder Head ... Crack(s) in the upper surface of the cylinder head or an area between a water passage and an opening into the crankcase can allow coolant to get into the crankcase.Crack(s) in Cylinder Block ... Crack(s) in the cylinder block between a water passage and the crankcase will let coolant get into the crankcase.*Authorized dealers are equipped with the necessary tools and personnel familiar with disassembly and assembly procedures

Have questions with 106661-4000?

Group cross 106661-4000 ZEXEL

Daihatsu

106661-4000

9 400 616 602

M121610010A

INJECTION-PUMP ASSEMBLY

M2

M2