Information injection-pump assembly

BOSCH

9 400 616 596

9400616596

ZEXEL

106661-2152

1066612152

MITSUBISHI

ME056871

me056871

Rating:

Service parts 106661-2152 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.

NOZZLE SET

Include in #1:

106661-2152

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 596

9400616596

ZEXEL

106661-2152

1066612152

MITSUBISHI

ME056871

me056871

Zexel num

Bosch num

Firm num

Name

106661-2152

9 400 616 596

ME056871 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T2 * K

6D22T2 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-6920

Overflow valve opening pressure

kPa

191

157

225

Overflow valve opening pressure

kgf/cm2

1.95

1.6

2.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

149

145.3

152.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

11.5

9.8

13.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

148

150

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.35

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

147.5

145.5

149.5

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_05

Adjusting point

E

Rack position

R1+1.25

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

174

170

178

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_06

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

131

91

171

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R2(R1-1.

7)

Boost pressure

kPa

6

6

6

Boost pressure

mmHg

45

45

45

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1-0.8

Boost pressure

kPa

10

8.7

11.3

Boost pressure

mmHg

75

65

85

Boost compensator adjustment_03

Pump speed

r/min

700

700

700

Rack position

R1(10.6)

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

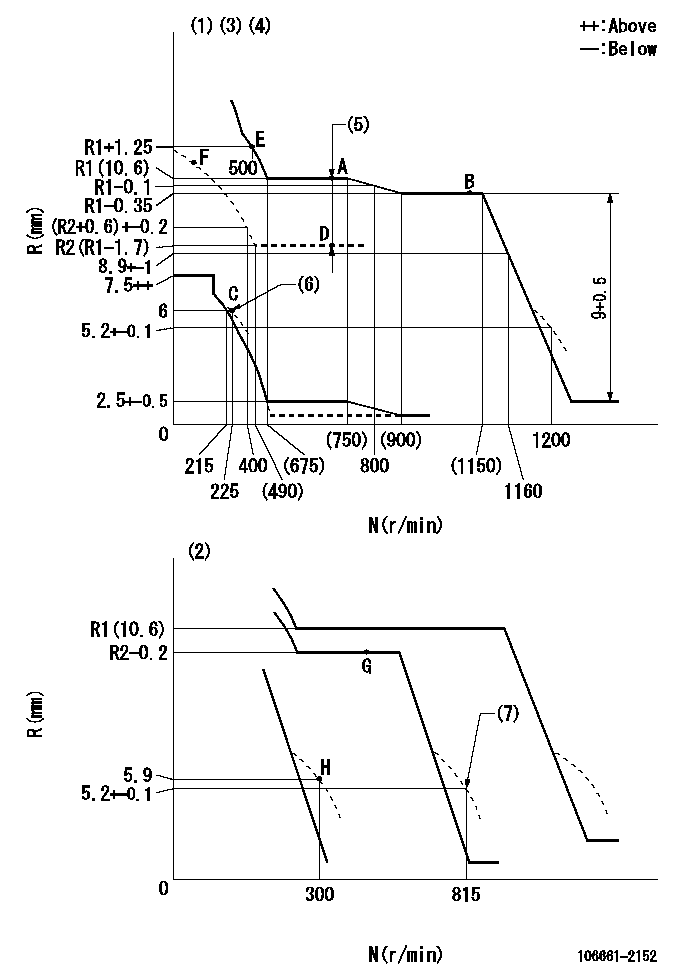

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Adjust with the load control lever in the full position (variable speed specification).

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator cancel stroke: BSL

(5)Boost compensator stroke: BCL

(6)Damper spring setting

(7)When air cylinder is operating.

----------

BSL=1.8mm BCL=1.7+-0.1mm

----------

----------

BSL=1.8mm BCL=1.7+-0.1mm

----------

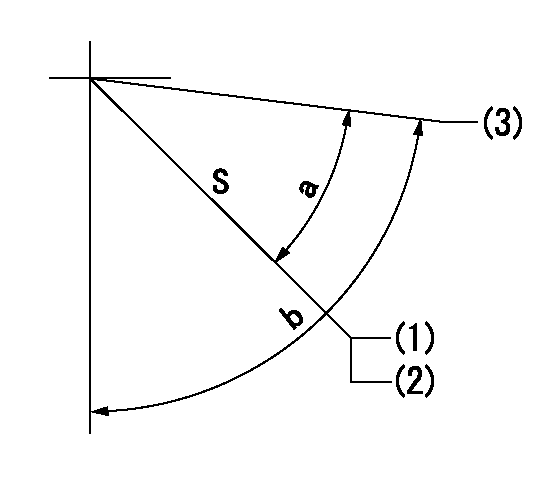

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

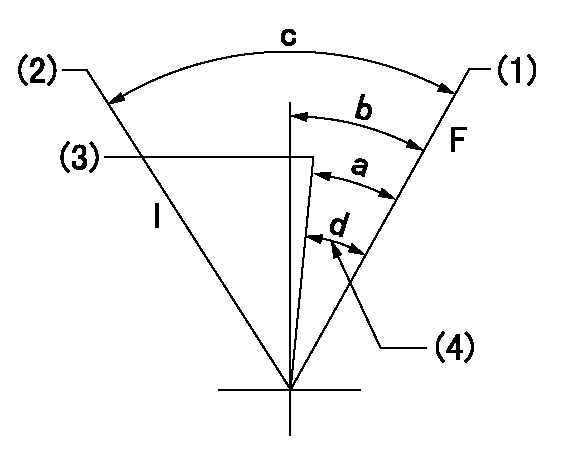

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Pump speed = bb

(3)Pump speed cc

(4)Air cylinder's adjustable range

----------

aa=1160r/min bb=300r/min cc=815r/min

----------

a=(11deg)+-5deg b=(12.5deg)+-5deg c=(20.5deg)+-5deg d=(11deg)

----------

aa=1160r/min bb=300r/min cc=815r/min

----------

a=(11deg)+-5deg b=(12.5deg)+-5deg c=(20.5deg)+-5deg d=(11deg)

0000000901

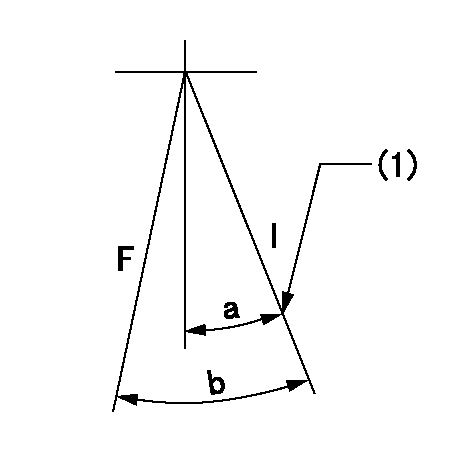

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=30deg+-3deg

----------

----------

a=28deg+-5deg b=30deg+-3deg

Stop lever angle

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Free (at delivery)

----------

aa=3.8-0.5mm

----------

a=37.5deg+7deg-5deg b=83deg+-5deg

----------

aa=3.8-0.5mm

----------

a=37.5deg+7deg-5deg b=83deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.7+-0.1mm

----------

----------

N1=325r/min Ra=5.7+-0.1mm

----------

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

0000001701 2-STAGE CHANGEOVER DEVICE

RFD governor 2 stage changeover mechanism adjustment outline

(A) Bolt

(B) bolt

(c) Nut

(D) Return spring

(E) Bolt

(F) Bolt

(G) Screw

(H) Bolt

(I) Load lever

(J) Speed lever

(K) Air cylinder

(M Air inlet

Figure 1 is only for reference. Lever shape, etc, may vary.

1. Minimum-maximum speed specification adjustment (when running)

(a) Without applying air to the air cylinder, loosen bolts (A) and (B).

(1)High speed return L setting

(a) In the speed range Nf~Nf - 300r/min, adjust using the speed adjusting bolt to determine the temporary beginning of high speed control speed.

(b) Determine the rack position in the vicinity of Rf using the full load lever.

(c) Increase speed and confirm return distance L.

(d) Adjust using the tension lever bolt to obtain L.

(2)Setting full load rack position Rf

(a) Move the load control lever to the full side.

(b) Adjust the full load adjusting bolt so that Rf can be obtained, then fix.

(3)Setting the beginning of high speed operation Nf

(a) Adjust using bolt (E) so that Nf can be obtained, and then fix.

(4)Idle control setting (Re, Ni, Rc)

(a) Set the speed at Ns + 200r/min and move the load control lever to the idle side.

(b) Fix the lever in the position where Re can be obtained.

(c) Next, decrease speed to Ni and screw in the idle spring.

(d) Adjust to obtain rack position Ri.

(e) Increase the speed and after confirming that the rack position is Re at Ns, set the speed at 0.

(f) Confirm protrusion position Rc at idle.

(5)Damper spring adjustment

(a) Increase speed and set the speed at the rack position Rd - 0.1 mm

(b) Set using the damper spring so that the rack position Rd can be obtained.

(c) When Rd is not specified, Rd = Ri - 0.5 mm.

(6)High speed droop confirmation

(a) Return the load control lever to the full load lever position.

(b) Increase the speed and confirm that Rf can be obtained at Nf r/min.

(c) Confirm that speed is Nh at rack position Rh.

2. Variable speed specification adjustment (at operation)

(a) Remove return spring (D).

(b) Apply air pressure of 245~294 kPa {2.5~3 kg/cm2} to the air cylinder.

(c) Perform the following adjustment in this condition.

(1)Setting full load rack position Rf'

(a) Pull the load lever to the idle side.

(b) Obtain rack position Rf' using the nut (C). (Pump speed is Nf'-50 r/min.)

(2)Setting full speed Nf'

(a) Adjust using bolt (B) so that Nf can be obtained, and then fix.

(3)Low speed side setting

(a) At 350r/min, set bolt (F) at beginning of governor operation position, then fix.

3. Bolt (A) adjustment

(1)Install return spring (D) and perform the adjustments below at air pressure 0.

(a) Set at speed Nf using bolt (E).

(b) Screw in bolt (A).

(c) Screw in 1 more turn from the speed lever contact position

(d) Fix bolt (A).

(e) At this time confirm that the air cylinder's shaft moves approximately 1 mm towards the governor.

4. Lever operation confirmation using the air cylinder

(1)Apply 588 kPa {6 kg/cm2} air pressure to the air cylinder.

(2)Confirm that the cylinder piston is moved 50 mm by the spring (D).

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(7deg)

----------

aa=9deg

----------

a=(7deg)

Information:

The fuel system consists of the transfer pump, fuel filter, shutoff solenoid, injection pumps, timing advance unit, governor, injection lines, nozzles and excess fuel return lines.The diaphragm-type fuel transfer pump mounts on the fuel injection pump housing and is driven by a lobe on the injection pump camshaft. The pump draws fuel from the vehicle supply tank and delivers it to a spin-on throw-away type filter. The filter is a combination primary-secondary element.Filtered fuel flows through a fuel shutoff solenoid, mounted on the fuel injection pump housing, into a fuel manifold. The solenoid operates electrically and stops fuel flow when the vehicle ignition system is off.Fuel in the manifold flows through the barrel assembly inlet port into the area above the injection pump plunger. During injection, the camshaft forces the plunger upward in the barrel. The end of the plunger closes the inlet port and forces the fuel out through high pressure injection lines to the nozzles.The injection nozzles are located under the valve cover and are held in place by clamps. The nozzle tip projects from the head into the cylinder bore. Atomized fuel is sprayed in a cone-shaped pattern through four orifices into the cylinder.During injection, a small amount of fuel leaks past the valve guide in the nozzle body to lubricate its moving parts. Any excess leakage flows from the nozzle to a fuel return manifold under the valve cover of each cylinder head. External lines connect the manifolds and return the fuel to the tank.Fuel Injection Pump Operation

Fuel enters the fuel injection pump housing from the fuel filter through the

Fuel enters the fuel injection pump housing from the fuel filter through the

Have questions with 106661-2152?

Group cross 106661-2152 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

106661-2152

9 400 616 596

ME056871

INJECTION-PUMP ASSEMBLY

6D22T2

6D22T2