Information injection-pump assembly

BOSCH

9 400 616 590

9400616590

ZEXEL

106661-2051

1066612051

MITSUBISHI

ME056799

me056799

Rating:

Service parts 106661-2051 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056804

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/24.5{250}

15.

NOZZLE SET

Include in #1:

106661-2051

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 590

9400616590

ZEXEL

106661-2051

1066612051

MITSUBISHI

ME056799

me056799

Zexel num

Bosch num

Firm num

Name

9 400 616 590

ME056799 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T6 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T6 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-6920

Overflow valve opening pressure

kPa

191

157

225

Overflow valve opening pressure

kgf/cm2

1.95

1.6

2.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.2

Pump speed

r/min

650

650

650

Each cylinder's injection qty

mm3/st.

138.5

135.1

141.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.5+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

17.5

14.9

20.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.2)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

138.5

137.5

139.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

27.3

27.3

Boost pressure

mmHg

205

205

Injection quantity adjustment_04

Adjusting point

D

Rack position

8.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

101.5

98.5

104.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

115

155

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.6

Boost pressure

kPa

5.3

5.3

5.3

Boost pressure

mmHg

40

40

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(10.2)

Boost pressure

kPa

14

14

14

Boost pressure

mmHg

105

105

105

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Load

3/4

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Load

4/4

Remarks

Finish

Finish

Test data Ex:

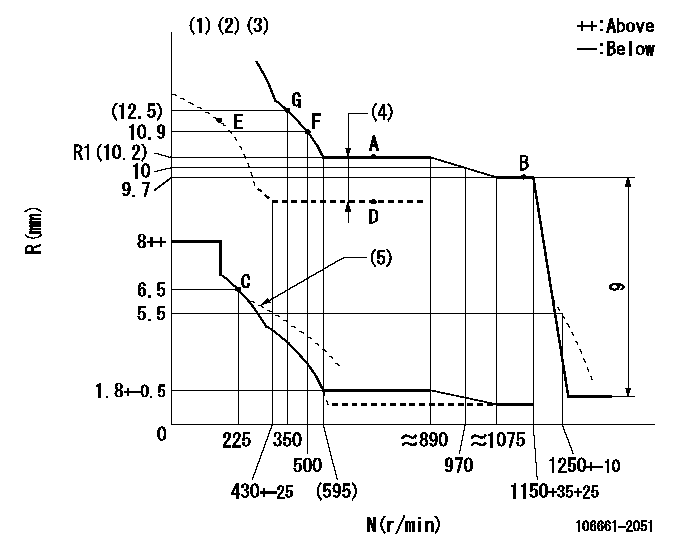

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Boost compensator cancel stroke: BSL

(4)Boost compensator stroke: BCL

(5)Damper spring setting: DL

----------

RT=1 TH=2.1mm BSL=1.6mm BCL=1.6+-0.1mm DL=6.2-0.2mm

----------

----------

RT=1 TH=2.1mm BSL=1.6mm BCL=1.6+-0.1mm DL=6.2-0.2mm

----------

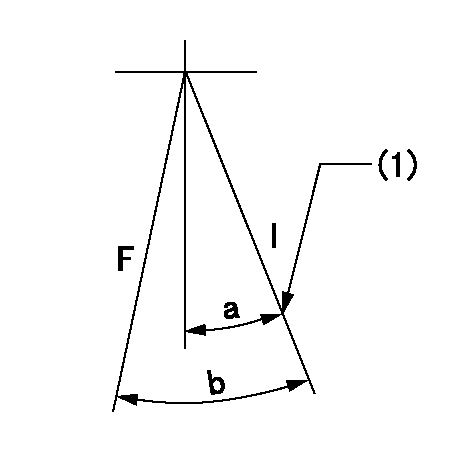

Speed control lever angle

F:Full speed

----------

----------

a=15.5deg+-5deg

----------

----------

a=15.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=31deg+-3deg

----------

----------

a=28deg+-5deg b=31deg+-3deg

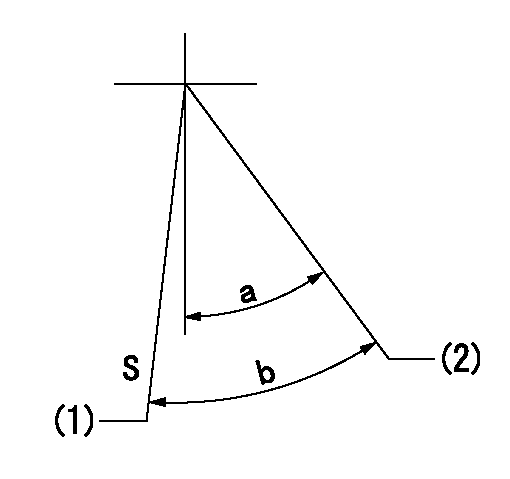

Stop lever angle

S:Stop the pump.

(1)Rack position = aa

(2)Free (at shipping)

----------

aa=3.4-0.5mm

----------

a=35.5deg+-5deg b=38.5deg+7deg-5deg

----------

aa=3.4-0.5mm

----------

a=35.5deg+-5deg b=38.5deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=6.2mm

----------

----------

N1=325+-5r/min Ra=6.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(7deg)

----------

aa=13deg

----------

a=(7deg)

Information:

This engine has a pressurized cooling system. Coolant is circulated by a belt driven, centrifugal type water pump. A water temperature regulator, located at the left front of the cylinder head, restricts coolant flow through the radiator until the coolant reaches operating temperature.The water pump has two outlets. One outlet directs coolant through a passage in the water temperature regulator housing to the aftercooler, to lower the temperature of inlet air in the inlet manifold. The other water outlet directs coolant through a water manifold in the side of the cylinder block, to cool engine lubricating oil. Coolant flows from the water manifold around the cylinder liners, into the cylinder head and around the precombustion chambers. Both streams of water join at the water temperature regulator. The water cooled air compressor receives coolant through a tube that is connected to the water manifold in the side of the cylinder block. Coolant returns through a tube from the air compressor head to the diesel engine cylinder head.Until the coolant reaches the temperature required to open the temperature regulator, coolant bypasses the radiator and flows directly back to the water pump.When the coolant reaches the temperature required to open the temperature regulator, coolant is then directed through the radiator.A pressure relief cap assembly is used to control the pressure in the cooling system, and prevents loss of coolant through the radiator overflow tube.Pressurizing the cooling system serves two purposes. First, it permits safe operation at coolant temperatures higher than the normal boiling point, providing a margin of cooling for intermittent peak loads. Secondly, it prevents cavitation in the water pump, and reduces the possibility of air or steam pockets forming in the coolant passages. Proper operation of the pressure relief cap assembly is essential. A pressure relief cap allows pressure (and some water, if the cooling system is too full) to escape when the pressure in the cooling system exceeds the capacity of the pressure cap. Loss of pressure will cause steam to form when coolant temperature is above the normal boiling point.Water Pump

The centrifugal-type water pump has two seals, one prevents leakage of water and the other prevents leakage of lubricant.An opening in the bottom of the pump housing, allows any leakage at the water seal or the rear bearing oil seal to escape.Fan

The fan is driven by three V-belts, from a pulley on the crankshaft. Belt tension is adjusted by moving the bracket assembly which includes the fan mounting and pulley.Water Temperature Regulator

The water temperature regulator restricts the flow of coolant through the radiator, until the coolant reaches operating temperature; approximately 165°F (74°C.) The regulator is fully open at approximately 180°F (82°C.)The shunt cooling system is used in many truck installations. The shunt cooling system provides continuous circulation which helps prevent aeration and pump cavitation by maintaining a positive head of water at the pump inlet at all times. It differs from the conventional cooling system in that the radiator top tank is divided into two compartments (upper

The centrifugal-type water pump has two seals, one prevents leakage of water and the other prevents leakage of lubricant.An opening in the bottom of the pump housing, allows any leakage at the water seal or the rear bearing oil seal to escape.Fan

The fan is driven by three V-belts, from a pulley on the crankshaft. Belt tension is adjusted by moving the bracket assembly which includes the fan mounting and pulley.Water Temperature Regulator

The water temperature regulator restricts the flow of coolant through the radiator, until the coolant reaches operating temperature; approximately 165°F (74°C.) The regulator is fully open at approximately 180°F (82°C.)The shunt cooling system is used in many truck installations. The shunt cooling system provides continuous circulation which helps prevent aeration and pump cavitation by maintaining a positive head of water at the pump inlet at all times. It differs from the conventional cooling system in that the radiator top tank is divided into two compartments (upper