Information injection-pump assembly

BOSCH

9 400 616 585

9400616585

ZEXEL

106661-0903

1066610903

NISSAN-DIESEL

1670096567

1670096567

Rating:

Cross reference number

BOSCH

9 400 616 585

9400616585

ZEXEL

106661-0903

1066610903

NISSAN-DIESEL

1670096567

1670096567

Zexel num

Bosch num

Firm num

Name

106661-0903

9 400 616 585

1670096567 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PE6T * K

PE6T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

164.2

162.2

166.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_02

Adjusting point

B

Rack position

6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9.1

8.1

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.8

Boost pressure

kPa

12

9.3

12

Boost pressure

mmHg

90

70

90

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

13

Boost pressure

kPa

26.7

26.7

26.7

Boost pressure

mmHg

200

200

200

Timer adjustment

Pump speed

r/min

925

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

1.1

0.6

1.6

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

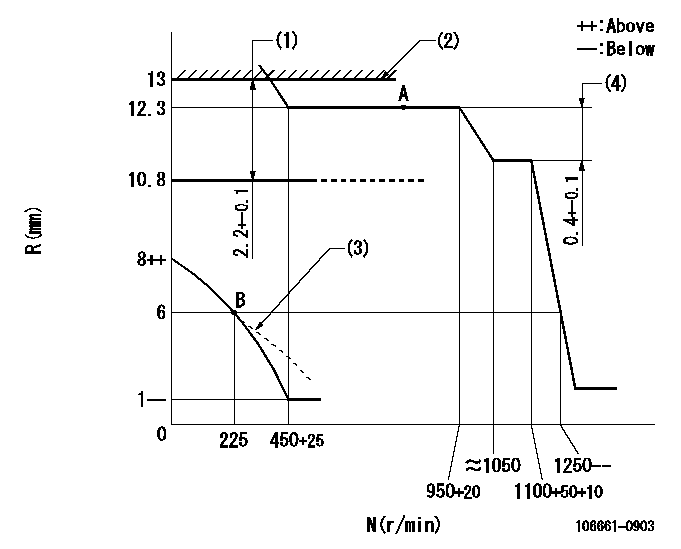

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator stroke

(2)Rack limit using stop lever

(3)Beginning of damper spring operation: DL

(4)Rack difference between N = N1 and N = N2

----------

DL=4.8-0.2mm N1=1100r/min N2=650r/min

----------

----------

DL=4.8-0.2mm N1=1100r/min N2=650r/min

----------

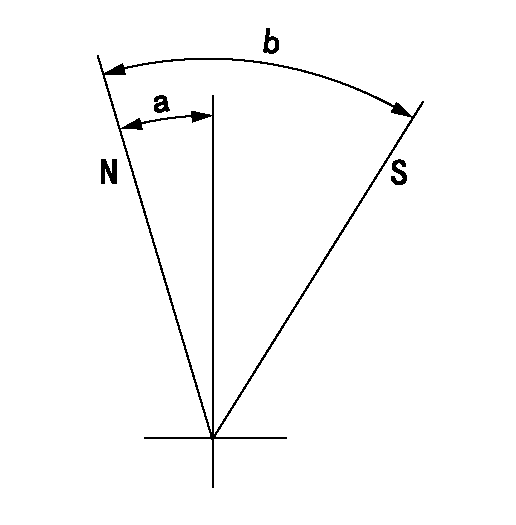

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=15deg+-5deg b=24deg+-3deg

----------

----------

a=15deg+-5deg b=24deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=5.5deg+-5deg b=39.5deg+-5deg

----------

----------

a=5.5deg+-5deg b=39.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Introduction

Do not perform any of the following procedure or order parts until you have read and understand the procedure. The procedure that follows below covers that installation of the new Diesel Exhaust Fluid (DEF) filter.Required Parts

Table 1 below contain the parts needed to complete the installation of the new DEF filter.Note: Only one DEF filter group is required per engine. Use Table 2 to determine which filter is the appropriate filter for each DEF header. Illustration 1 shows the location of the DEF header part number.

Table 1

Item Qty Part Number Part Description

1 1 452-6055 Filter Base As

2 1 453-1604(1) Diesel Exhaust Fluid Filter Gp

3 1 453-1605***#i05999309/d1820e940*** Diesel Exhaust Fluid Filter Gp

4 1 453-1606***#i05999309/d1820e940*** Diesel Exhaust Fluid Filter Gp

5 1 378-3187 Diesel Exhaust Fluid Filter Gp

6 1 423-3251 Connector

7 1 425-0385 Filter As

8 1 391-5262 Gasket

(1) Use Table 2 to choose the correct part that corresponds to the DEF header

Illustration 1 g03745839

(1) Location of DEF header part number

Table 2

DEF Header Part Number Required DEF Filter

434-3241 453-1604

434-3242 453-1605

434-3243 453-1606 Installation Procedure

Illustration 2 g03736523

(1) DEF header

(2) DEF filter

(3) DEF tank

(4) DEF header bolts

Clean the area around DEF header (1). Clear any dirt or debris that could contaminate the DEF tank or lines when removed. Note: If proper cleaning is not performed, DEF pump performance issues or failure may occur.

Disconnect the two DEF lines, two coolant lines, and harness from the DEF header assembly.

Remove the six DEF header screws (4) from the DEF header assembly. Note: Do not discard the screws that secure the DEF header assembly to the DEF tank. The screws will be reused in a later step.

Remove the DEF header assembly. Remove the previous DEF header gasket and discard.

Illustration 3 g03736534

(5) 452-6055 Filter Base As

Install filter base assembly (5) onto the DEF header assembly. Note: Each half of the adapter has two small locking tabs that secure to the bottom side of the DEF header assembly.

Remove the previous 425-0385 Filter As located at the bottom of the DEF pick-up tube.

Install the new 425-0385 Filter As onto the DEF header assembly.

Illustration 4 g03736545

(6) Band clamp

Install the correct DEF filter onto the DEF header adapter and secure using band clamp (6) that is supplied. Torque the band clamp to 4.5 0.7 N m (40 6 lb in).

Install the DEF header assembly back into the DEF tank. Secure the DEF header to the DEF tank using the six screws previously removed in Step 3. Torque the six screws to 5 1 N m (44 9 lb in).

Reconnect the harness, coolant lines, and DEF lines to the DEF header.

Illustration 5 g03736566

(7) DEF pump inlet filter fitting

(8) Main DEF pump filter

Replace DEF pump inlet filter fitting (7) and main DEF pump filter (8). Refer to Disassembly and Assembly, UENR0132, "Diesel Exhaust Fluid Filter - Remove and Install" for the replacement procedure.

Do not perform any of the following procedure or order parts until you have read and understand the procedure. The procedure that follows below covers that installation of the new Diesel Exhaust Fluid (DEF) filter.Required Parts

Table 1 below contain the parts needed to complete the installation of the new DEF filter.Note: Only one DEF filter group is required per engine. Use Table 2 to determine which filter is the appropriate filter for each DEF header. Illustration 1 shows the location of the DEF header part number.

Table 1

Item Qty Part Number Part Description

1 1 452-6055 Filter Base As

2 1 453-1604(1) Diesel Exhaust Fluid Filter Gp

3 1 453-1605***#i05999309/d1820e940*** Diesel Exhaust Fluid Filter Gp

4 1 453-1606***#i05999309/d1820e940*** Diesel Exhaust Fluid Filter Gp

5 1 378-3187 Diesel Exhaust Fluid Filter Gp

6 1 423-3251 Connector

7 1 425-0385 Filter As

8 1 391-5262 Gasket

(1) Use Table 2 to choose the correct part that corresponds to the DEF header

Illustration 1 g03745839

(1) Location of DEF header part number

Table 2

DEF Header Part Number Required DEF Filter

434-3241 453-1604

434-3242 453-1605

434-3243 453-1606 Installation Procedure

Illustration 2 g03736523

(1) DEF header

(2) DEF filter

(3) DEF tank

(4) DEF header bolts

Clean the area around DEF header (1). Clear any dirt or debris that could contaminate the DEF tank or lines when removed. Note: If proper cleaning is not performed, DEF pump performance issues or failure may occur.

Disconnect the two DEF lines, two coolant lines, and harness from the DEF header assembly.

Remove the six DEF header screws (4) from the DEF header assembly. Note: Do not discard the screws that secure the DEF header assembly to the DEF tank. The screws will be reused in a later step.

Remove the DEF header assembly. Remove the previous DEF header gasket and discard.

Illustration 3 g03736534

(5) 452-6055 Filter Base As

Install filter base assembly (5) onto the DEF header assembly. Note: Each half of the adapter has two small locking tabs that secure to the bottom side of the DEF header assembly.

Remove the previous 425-0385 Filter As located at the bottom of the DEF pick-up tube.

Install the new 425-0385 Filter As onto the DEF header assembly.

Illustration 4 g03736545

(6) Band clamp

Install the correct DEF filter onto the DEF header adapter and secure using band clamp (6) that is supplied. Torque the band clamp to 4.5 0.7 N m (40 6 lb in).

Install the DEF header assembly back into the DEF tank. Secure the DEF header to the DEF tank using the six screws previously removed in Step 3. Torque the six screws to 5 1 N m (44 9 lb in).

Reconnect the harness, coolant lines, and DEF lines to the DEF header.

Illustration 5 g03736566

(7) DEF pump inlet filter fitting

(8) Main DEF pump filter

Replace DEF pump inlet filter fitting (7) and main DEF pump filter (8). Refer to Disassembly and Assembly, UENR0132, "Diesel Exhaust Fluid Filter - Remove and Install" for the replacement procedure.

Have questions with 106661-0903?

Group cross 106661-0903 ZEXEL

Nissan-Diesel

Nissan-Diesel

106661-0903

9 400 616 585

1670096567

INJECTION-PUMP ASSEMBLY

PE6T

PE6T