Information injection-pump assembly

ZEXEL

106661-0901

1066610901

Rating:

Cross reference number

ZEXEL

106661-0901

1066610901

Zexel num

Bosch num

Firm num

Name

106661-0901

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

164.2

162.2

166.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_02

Adjusting point

B

Rack position

6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9.1

8.1

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.8

Boost pressure

kPa

12

9.3

12

Boost pressure

mmHg

90

70

90

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

13

Boost pressure

kPa

26.7

26.7

26.7

Boost pressure

mmHg

200

200

200

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.1

0.6

1.6

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

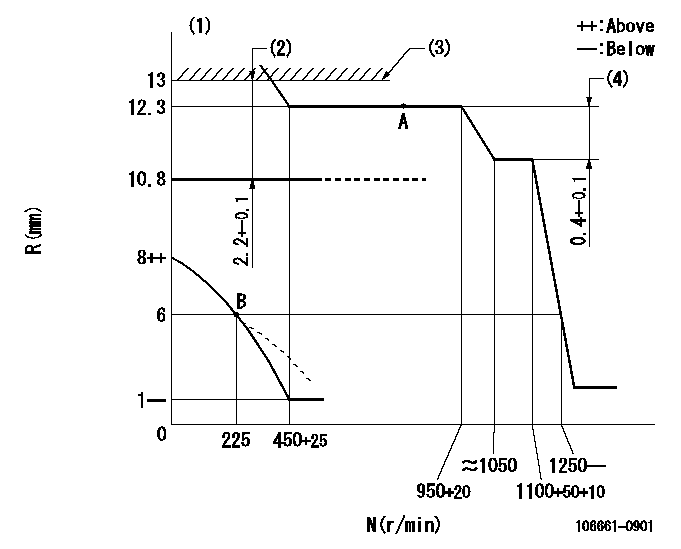

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost compensator stroke

(3)Rack limit using stop lever

(4)Rack difference between N = N1 and N = N2

----------

DL=4.8-0.2mm N1=1100r/min N2=650r/min

----------

----------

DL=4.8-0.2mm N1=1100r/min N2=650r/min

----------

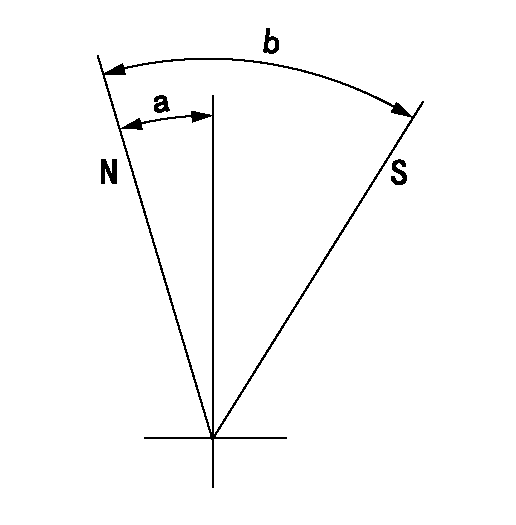

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=15deg+-5deg b=24deg+-3deg

----------

----------

a=15deg+-5deg b=24deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=5.5deg+-5deg b=39.5deg+-5deg

----------

----------

a=5.5deg+-5deg b=39.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Never use water alone as a coolant. Water alone is corrosive at engine operating temperatures. In addition, water alone does not provide adequate protection against boiling or freezing.

In engine cooling systems that use water alone, Caterpillar recommends the use of Cat SCA. Cat SCA helps to prevent the following conditions from occurring:

Corrosion

Formation of mineral deposits

Cavitation erosion of the cylinder liner

Foaming of the coolantIf Cat SCA is not used, select a fully formulated commercial SCA. The commercial SCA must provide a minimum of 2400 mg/L or 2400 ppm (140 grains/US gal) of nitrites in the final coolant mixture.The quality of the water is an important factor in this type of cooling system. Distilled water or deionized water is recommended for use in cooling systems. If distilled water or deionized water is not available, use water that meets or exceeds the minimum requirements that are listed in the table for recommended water properties in this Special Publication, "General Coolant Information" topic.A cooling system that uses a mixture of SCA and water only needs more SCA. The SCA concentration in a cooling system that uses SCA and water should be 6 to 8 percent by volume.Maintain the Cat SCA in the same way as you would maintain a cooling system that uses heavy-duty coolant/antifreeze. Adjust the maintenance for the amount ofCat SCA additions.Adding the Cat SCA to Water at the Initial Fill

Use the equation that is in this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" to determine the amount of Cat SCA that is required at the initial fill. This equation is for a mixture of only Cat SCA and water.Adding the Cat SCA to Water for Maintenance

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Submit a coolant sample to your Cat dealer. See this Special Publication, "S O S Services Coolant Analysis" topic.Additions of Cat SCA are based on the results of the coolant analysis. The size of the cooling system determines the amount of Cat SCA that is required.Use the equation that is in this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" to determine the amount of Cat SCA that is required for maintenance, if necessary:Note: Specific engine applications may require maintenance practices to be periodically evaluated in order to maintain properly the engine cooling system.SCA and part numbers are available from your Cat dealer.

Have questions with 106661-0901?

Group cross 106661-0901 ZEXEL

Nissan-Diesel

106661-0901

INJECTION-PUMP ASSEMBLY