Information injection-pump assembly

ZEXEL

106661-0710

1066610710

NISSAN-DIESEL

1670096111

1670096111

Rating:

Cross reference number

ZEXEL

106661-0710

1066610710

NISSAN-DIESEL

1670096111

1670096111

Zexel num

Bosch num

Firm num

Name

106661-0710

1670096111 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PD6 *

PD6 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

139.4

137.4

141.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.9

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

114.6

112.6

116.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

139.7

137.7

141.7

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

11.7

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

138.8

136.8

140.8

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.2+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

10.1

9.1

11.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_06

Adjusting point

-

Rack position

-

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

139.4

138.4

140.4

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

53.3

Boost pressure

mmHg

400

400

400

Remarks

Set full load lever

Set full load lever

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

10.9

Boost pressure

kPa

27.3

27.3

27.3

Boost pressure

mmHg

205

205

205

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

11.7

Boost pressure

kPa

42.7

41.4

44

Boost pressure

mmHg

320

310

330

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.2

0.1

0.6

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.7

0.3

1

Timer adjustment_04

Pump speed

r/min

1150+50

Advance angle

deg.

2.2

2

2.8

Remarks

Finish

Finish

Test data Ex:

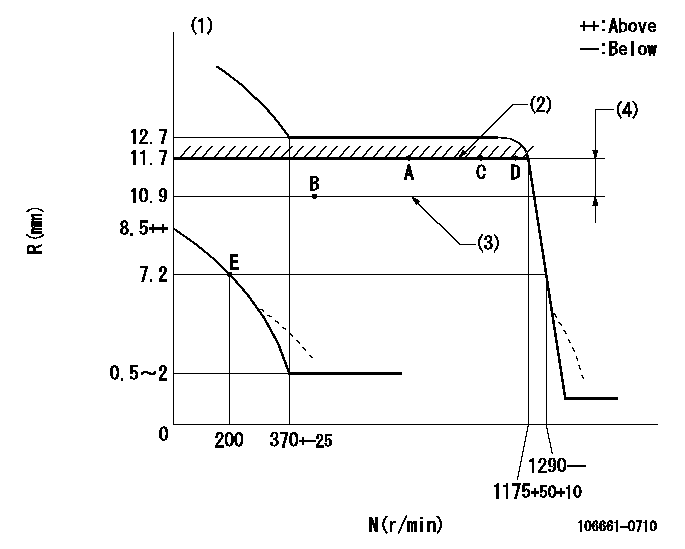

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost pressure: not exceeding BP1

(3)Boost pressure: not exceeding BP2

(4)Boost compensator stroke

----------

DL=5.2+0.5mm BP1=42.7+-1.3kPa(320+-10mmHg) BP2=(27.3)kPa((205)mmHg)

----------

----------

DL=5.2+0.5mm BP1=42.7+-1.3kPa(320+-10mmHg) BP2=(27.3)kPa((205)mmHg)

----------

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=13.5deg+-5deg b=23.5deg+-3deg

----------

----------

a=13.5deg+-5deg b=23.5deg+-3deg

Information:

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Ensure that all adjustments and repairs that are carried out to the fuel system are performed by authorised personnel that have the correct training.Before begining ANY work on the fuel system, refer to Operation and Maintenance Manual, "General Hazard Information and High Pressure Fuel Lines" for safety information.Refer to Systems Operation, Testing and Adjusting Manual, "Cleanliness of Fuel System Components" for detailed information on the standards of cleanliness that must be observed

Have questions with 106661-0710?

Group cross 106661-0710 ZEXEL

Nissan-Diesel

Nissan-Diesel

106661-0710

1670096111

INJECTION-PUMP ASSEMBLY

PD6

PD6