Information injection-pump assembly

ZEXEL

106661-0650

1066610650

Rating:

Cross reference number

ZEXEL

106661-0650

1066610650

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

740

740

740

Average injection quantity

mm3/st.

122

120

124

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.7

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

98.6

96.6

100.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.3

11.6

15

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.7

Boost pressure

kPa

6.7

4

9.4

Boost pressure

mmHg

50

30

70

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

11.3

Boost pressure

kPa

15.3

15.3

15.3

Boost pressure

mmHg

115

115

115

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.75

0.4

1.1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.25

0.9

1.6

Timer adjustment_04

Pump speed

r/min

1100+50

Advance angle

deg.

2.5

1.9

2.7

Remarks

Finish

Finish

Test data Ex:

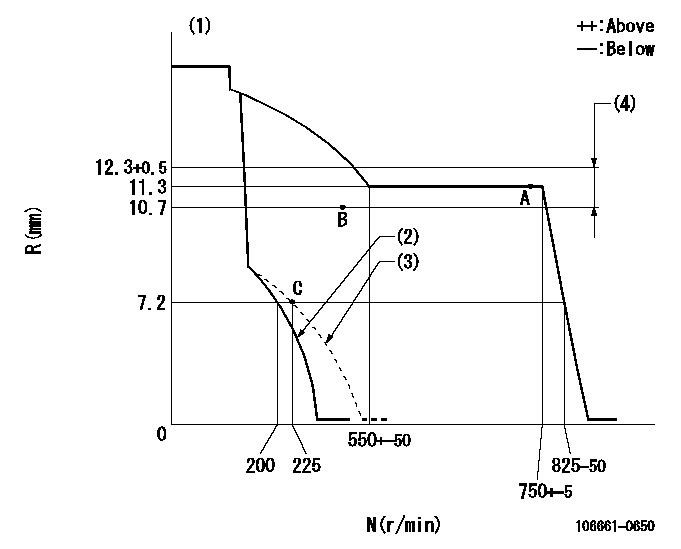

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Stop lever setting

(3)Set idle sub-spring

(4)Boost compensator stroke

----------

K=15

----------

----------

K=15

----------

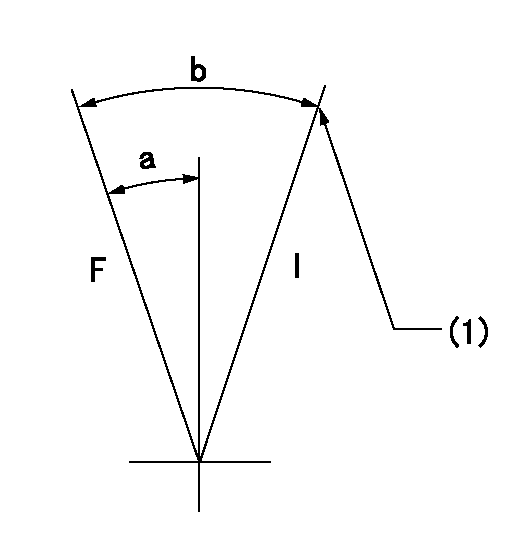

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=23deg+-3deg

----------

----------

a=5deg+-5deg b=23deg+-3deg

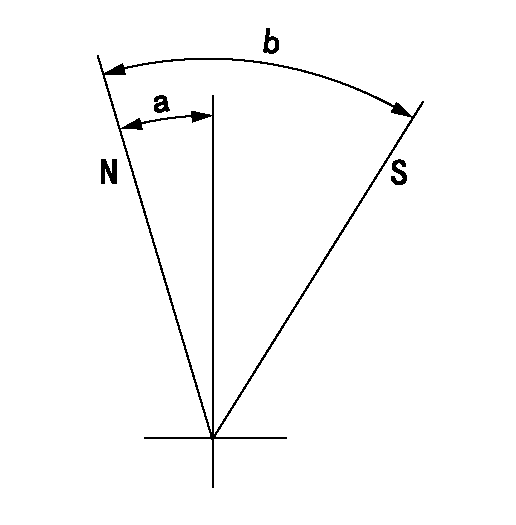

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

Information:

Parts Location

Illustration 2 g01601133

(1) 308-4927 Diesel Particulate Filter and Mounting Gp (2) 235-3963 Clamp As (3) 308-4930 Bracket As (4) 8T-4183 Bolt (5) 5P-8245 Hard Washer (6) 5P-1076 Hard Washer Installation Procedure

Diesel Particulate Filter Installation

Illustration 3 g01624741

Left side view (typical example) (12) Muffler assembly (existing) (13) Bracket assembly (existing) (14) Bolt (existing) (15) Washer (existing)

Illustration 4 g01624810

Rear view (typical example) (16) Bolt (existing) (17) Hard washer (existing) (18) Muffler clamp (existing) (19) Tube assembly (existing)

Remove muffler assembly (12). Retain muffler clamp (18). The muffler clamp will be reused in Step 8. Refer to Illustrations 3 and 4.Note: A new 289-2492 Muffler Clamp (11) will be needed if the original muffler clamp cannot be reused.

Remove bracket assembly (13). Retain five bolts (14), five washers (15), two bolts (16), and two hard washers (17) that were used to secure bracket assembly (13). These parts will be reused in Step 3.

Illustration 5 g01601033

(3) 308-4930 Bracket As (4) 8T-4183 Bolt (6) 5P-1076 Hard Washer

Reuse five bolts (14), and five washers (15) to secure the new 308-4930 Bracket As (3) to the flywheel housing. Refer to Illustration 5.

Reuse two bolts (16), and two hard washers (17) to secure bracket assembly (3) to the engine lifting plate. Refer to Illustration 5.

Install two new 8T-4183 Bolts (4), and two new 5P-1076 Hard Washers (6) to the other side of bracket assembly (3) so that the bracket assembly is bolted to the engine and to the enclosure on both sides. Refer to Illustration 5.

Illustration 6 g01601025

(2) 235-3963 Clamp As (Bottom half) (4) 8T-4183 Bolt (5) 5P-8245 Hard Washer

Remove the two bolts, two hard washers, two lockwashers, and two nuts from the new 235-3963 Clamp As (2). Repeat for the other new clamp assembly (2). Retain these parts along with the upper half of the clamp assembly. These parts will be reinstalled in Step 9.

Install the bottom half of 235-3963 Clamp As (2) by using two new 8T-4183 Bolts (4) and two new 5P-8245 Hard Washers (5). Loosely secure these bolts so that the clamp assembly is adjustable. Repeat for the other clamp assembly. Refer to Illustration 6.

Illustration 7 g01601013

(1) 308-4927 Diesel Particulate Filter and Mounting Gp (2) 235-3963 Clamp As (Top half) (2a) Bolt (2b) Hard washer (2c) Lockwasher (2d) Nut (20) Inlet module tube

Install the new 308-4927 Diesel Particulate Filter and Mounting Gp (1) on top of clamp assemblies (2). The weight of the diesel particulate filter group is approximately 34 kg (75 lb). Make sure that inlet module tube (20) fits into tube assembly (19). Secure the inlet module tube to the tube assembly by using original muffler clamp (18). If the original muffler clamp (18) cannot be reused, use a new 289-2492 Muffler Clamp (11) to secure the connection. This clamp is not included in the kit. Refer to Illustration 7.

Once you have the

Illustration 2 g01601133

(1) 308-4927 Diesel Particulate Filter and Mounting Gp (2) 235-3963 Clamp As (3) 308-4930 Bracket As (4) 8T-4183 Bolt (5) 5P-8245 Hard Washer (6) 5P-1076 Hard Washer Installation Procedure

Diesel Particulate Filter Installation

Illustration 3 g01624741

Left side view (typical example) (12) Muffler assembly (existing) (13) Bracket assembly (existing) (14) Bolt (existing) (15) Washer (existing)

Illustration 4 g01624810

Rear view (typical example) (16) Bolt (existing) (17) Hard washer (existing) (18) Muffler clamp (existing) (19) Tube assembly (existing)

Remove muffler assembly (12). Retain muffler clamp (18). The muffler clamp will be reused in Step 8. Refer to Illustrations 3 and 4.Note: A new 289-2492 Muffler Clamp (11) will be needed if the original muffler clamp cannot be reused.

Remove bracket assembly (13). Retain five bolts (14), five washers (15), two bolts (16), and two hard washers (17) that were used to secure bracket assembly (13). These parts will be reused in Step 3.

Illustration 5 g01601033

(3) 308-4930 Bracket As (4) 8T-4183 Bolt (6) 5P-1076 Hard Washer

Reuse five bolts (14), and five washers (15) to secure the new 308-4930 Bracket As (3) to the flywheel housing. Refer to Illustration 5.

Reuse two bolts (16), and two hard washers (17) to secure bracket assembly (3) to the engine lifting plate. Refer to Illustration 5.

Install two new 8T-4183 Bolts (4), and two new 5P-1076 Hard Washers (6) to the other side of bracket assembly (3) so that the bracket assembly is bolted to the engine and to the enclosure on both sides. Refer to Illustration 5.

Illustration 6 g01601025

(2) 235-3963 Clamp As (Bottom half) (4) 8T-4183 Bolt (5) 5P-8245 Hard Washer

Remove the two bolts, two hard washers, two lockwashers, and two nuts from the new 235-3963 Clamp As (2). Repeat for the other new clamp assembly (2). Retain these parts along with the upper half of the clamp assembly. These parts will be reinstalled in Step 9.

Install the bottom half of 235-3963 Clamp As (2) by using two new 8T-4183 Bolts (4) and two new 5P-8245 Hard Washers (5). Loosely secure these bolts so that the clamp assembly is adjustable. Repeat for the other clamp assembly. Refer to Illustration 6.

Illustration 7 g01601013

(1) 308-4927 Diesel Particulate Filter and Mounting Gp (2) 235-3963 Clamp As (Top half) (2a) Bolt (2b) Hard washer (2c) Lockwasher (2d) Nut (20) Inlet module tube

Install the new 308-4927 Diesel Particulate Filter and Mounting Gp (1) on top of clamp assemblies (2). The weight of the diesel particulate filter group is approximately 34 kg (75 lb). Make sure that inlet module tube (20) fits into tube assembly (19). Secure the inlet module tube to the tube assembly by using original muffler clamp (18). If the original muffler clamp (18) cannot be reused, use a new 289-2492 Muffler Clamp (11) to secure the connection. This clamp is not included in the kit. Refer to Illustration 7.

Once you have the