Information injection-pump assembly

BOSCH

9 400 612 374

9400612374

ZEXEL

106471-2031

1064712031

MITSUBISHI-HEAV

3636510111

3636510111

Rating:

Service parts 106471-2031 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106471-2031

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 374

9400612374

ZEXEL

106471-2031

1064712031

MITSUBISHI-HEAV

3636510111

3636510111

Zexel num

Bosch num

Firm num

Name

9 400 612 374

3636510111 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S4B K 14BW INJECTION PUMP ASSY PE4P,4PD PE

S4B K 14BW INJECTION PUMP ASSY PE4P,4PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

157

157

Overflow valve opening pressure

kgf/cm2

1.6

1.6

1.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

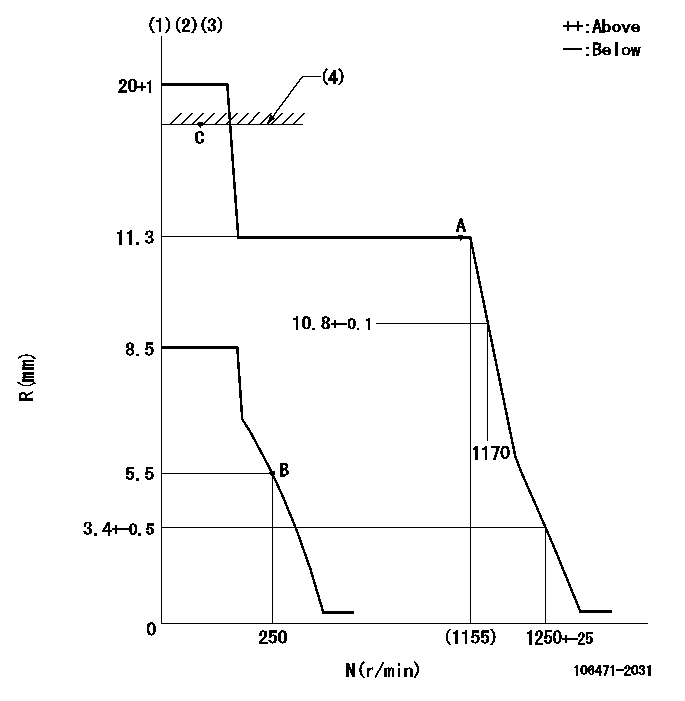

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

178

171

185

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

25.5

22.5

28.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

224

224

234

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

500

Advance angle

deg.

0.9

Timer adjustment_04

Pump speed

r/min

700

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_05

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Timer adjustment_06

Pump speed

r/min

1150

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Idle spring not operating.

(4)RACK LIMIT

----------

K=16

----------

----------

K=16

----------

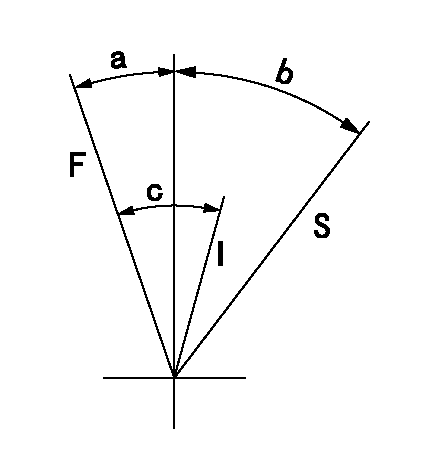

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=18deg+-5deg b=32deg+-3deg c=40deg+-5deg

----------

----------

a=18deg+-5deg b=32deg+-3deg c=40deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=50deg+-5deg b=53deg+-5deg

----------

----------

a=50deg+-5deg b=53deg+-5deg

Information:

Customer Specified Parameters

Customer Specified Parameters allow a customer to restrict how a operator operates the vehicle. Some parameters may affect engine operation in ways that the uninformed operator does not expect. These parameters may lead to power and/or performance complaints, even when the engine is operating to specifications. If the NEXG4512 Customer Parameter Configuration Aid, Service Program Module (Optional Electronic Service Tool) is installed in an ECAP equipped with the 8C9700 Rechargeable Portable Printer, a list of Customer Specified Parameters can be read from the ECM and printed out.Customer parameters may be changed repeatedly as a customer changes his operation. Customer Passwords are required to change these parameters.The following is a brief description of the Customer Specified Parameters. Along with each, are the minimum and maximum values for the parameter and the default value. If a feature is not used, the parameter should be programmed to the default value.Engine Parameters

Rating Number:Number of rating within the horsepower family. The personality module defines the horsepower family (such as 325 hp). This number defines which rating is used (such as 325 hp at 1900 rpm or 325 hp at 2100 rpm) within the family. Top Engine Limit (TEL):Maximum engine rpm when the engine is under load. The engine will still achieve rated rpm under no load.Minimum ... Map (Rating) DependentMaximum ... Rated rpm + 20 rpmDefault ... Rated rpm + 20 rpm Top engine limiting with the 3176 has no governor overrun (it is an isochronous setting with no droop). Low Idle RPM:Minimum engine rpm.Minimum ... 600 rpmMaximum ... 750 rpmDefault ... 700 rpm Vehicle ID:Identification of vehicle assigned by customer. Used only for customer reference; not used by the ECM.Factory Passwords

Factory Passwords are required to perform any one of these four functions:1. Program a new ECM. When an ECM is replaced, the System Configuration Parameters must be programmed into the new ECM. These parameters are protected by Factory Passwords.2. Rerate the engine to another engine family. This requires changing the Personality Module Code, which is protected by Factory Passwords.3. Read Customer Passwords. If the owner forgets his Customer Passwords, he will not be able to program Customer Specified Parameters. Using factory passwords, one can read Customer Passwords, then use those Customer Passwords to program Customer Specified Parameters.4. Clear certain diagnostic codes. Only Diagnostic Code 35 (Engine Overspeed) requires Factory Passwords to clear once it is LOGGED. Clearing certain other codes requires Customer Passwords. The majority of LOGGED diagnostic codes require no passwords to clear.Factory Passwords are controlled by Caterpillar and may only be obtained by authorized Caterpillar Dealers. Since factory passwords contain alphabetic characters, only the ECAP may perform these functions.To obtain factory passwords, proceed as if you already had the password. At some point, if factory passwords are truly needed, the ECAP will request factory passwords and will provide most of the information required to obtain the password on the ECAP screen.Customer Passwords

Customer Passwords are required to change ANY Customer Parameter. Customer Specified Parameters are those

Customer Specified Parameters allow a customer to restrict how a operator operates the vehicle. Some parameters may affect engine operation in ways that the uninformed operator does not expect. These parameters may lead to power and/or performance complaints, even when the engine is operating to specifications. If the NEXG4512 Customer Parameter Configuration Aid, Service Program Module (Optional Electronic Service Tool) is installed in an ECAP equipped with the 8C9700 Rechargeable Portable Printer, a list of Customer Specified Parameters can be read from the ECM and printed out.Customer parameters may be changed repeatedly as a customer changes his operation. Customer Passwords are required to change these parameters.The following is a brief description of the Customer Specified Parameters. Along with each, are the minimum and maximum values for the parameter and the default value. If a feature is not used, the parameter should be programmed to the default value.Engine Parameters

Rating Number:Number of rating within the horsepower family. The personality module defines the horsepower family (such as 325 hp). This number defines which rating is used (such as 325 hp at 1900 rpm or 325 hp at 2100 rpm) within the family. Top Engine Limit (TEL):Maximum engine rpm when the engine is under load. The engine will still achieve rated rpm under no load.Minimum ... Map (Rating) DependentMaximum ... Rated rpm + 20 rpmDefault ... Rated rpm + 20 rpm Top engine limiting with the 3176 has no governor overrun (it is an isochronous setting with no droop). Low Idle RPM:Minimum engine rpm.Minimum ... 600 rpmMaximum ... 750 rpmDefault ... 700 rpm Vehicle ID:Identification of vehicle assigned by customer. Used only for customer reference; not used by the ECM.Factory Passwords

Factory Passwords are required to perform any one of these four functions:1. Program a new ECM. When an ECM is replaced, the System Configuration Parameters must be programmed into the new ECM. These parameters are protected by Factory Passwords.2. Rerate the engine to another engine family. This requires changing the Personality Module Code, which is protected by Factory Passwords.3. Read Customer Passwords. If the owner forgets his Customer Passwords, he will not be able to program Customer Specified Parameters. Using factory passwords, one can read Customer Passwords, then use those Customer Passwords to program Customer Specified Parameters.4. Clear certain diagnostic codes. Only Diagnostic Code 35 (Engine Overspeed) requires Factory Passwords to clear once it is LOGGED. Clearing certain other codes requires Customer Passwords. The majority of LOGGED diagnostic codes require no passwords to clear.Factory Passwords are controlled by Caterpillar and may only be obtained by authorized Caterpillar Dealers. Since factory passwords contain alphabetic characters, only the ECAP may perform these functions.To obtain factory passwords, proceed as if you already had the password. At some point, if factory passwords are truly needed, the ECAP will request factory passwords and will provide most of the information required to obtain the password on the ECAP screen.Customer Passwords

Customer Passwords are required to change ANY Customer Parameter. Customer Specified Parameters are those