Information injection-pump assembly

BOSCH

F 01G 09W 0FS

f01g09w0fs

ZEXEL

104780-9960

1047809960

NISSAN-DIESEL

16700NA01A

16700na01a

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel VE Fuel Injection Pump, Compatible With NISSAN TD27 Engine Replacement Parts 104680-9960 104780-9960 NP-VE4/10F1050RNP2614 16700NA01A

CHENUXO Diesel VE Fuel Injection Pump , Compatible With NISSAN TD27 Engine Replacement Parts 104680-9960 104780-9960 NP-VE4/10F1050RNP2614 16700NA01A || Efficient and energy-saving: It can meet the fuel demand of the engine while reducing energy consumption, which helps to improve fuel economy. || High reliability: Adopting advanced manufacturing processes to effectively reduce wear and tear. Ensure stable operation in various harsh environments. || Optimization design: The installation site adopts soundproof and shock-absorbing materials, further reducing the propagation of noise. || Monitoring feedback: Real time monitoring of fuel pressure, temperature, liquid level and other parameters, and feedback to the ECU.

CHENUXO Diesel VE Fuel Injection Pump , Compatible With NISSAN TD27 Engine Replacement Parts 104680-9960 104780-9960 NP-VE4/10F1050RNP2614 16700NA01A || Efficient and energy-saving: It can meet the fuel demand of the engine while reducing energy consumption, which helps to improve fuel economy. || High reliability: Adopting advanced manufacturing processes to effectively reduce wear and tear. Ensure stable operation in various harsh environments. || Optimization design: The installation site adopts soundproof and shock-absorbing materials, further reducing the propagation of noise. || Monitoring feedback: Real time monitoring of fuel pressure, temperature, liquid level and other parameters, and feedback to the ECU.

Fuel Pump 104780-9960 1047809960 Compatible For NISSAN TD27 New Engine Replacement Parts Fuel Supply System Fuel Pumps

YPMOICBH The fuel pump allows the fuel tank to be placed away from the engine, making it easier for car design layout || When the engine stops, the control module turns off the power to the fuel pump to prevent accidental ignition || The fuel pump extracts fuel from the fuel tank and delivers it to the engine through the fuel supply pipeline, ensuring a continuous and stable fuel supply during engine operation || The fuel pump cooperates with the fuel pressure regulator to establish an appropriate fuel pressure, ensuring that the fuel can flow smoothly to the engine and meet the requirements of the injection system || Fuel Pump 104780-9960 1047809960 Compatible For NISSAN TD27 New Engine Replacement Parts Fuel Supply System Fuel Pumps

YPMOICBH The fuel pump allows the fuel tank to be placed away from the engine, making it easier for car design layout || When the engine stops, the control module turns off the power to the fuel pump to prevent accidental ignition || The fuel pump extracts fuel from the fuel tank and delivers it to the engine through the fuel supply pipeline, ensuring a continuous and stable fuel supply during engine operation || The fuel pump cooperates with the fuel pressure regulator to establish an appropriate fuel pressure, ensuring that the fuel can flow smoothly to the engine and meet the requirements of the injection system || Fuel Pump 104780-9960 1047809960 Compatible For NISSAN TD27 New Engine Replacement Parts Fuel Supply System Fuel Pumps

VE4 Fuel Injection Pump for Nissan TD27 Engine 104780-9960 16700-NA01A

KoovDem Part Number: 104780-9960, 1047809960, 16700-NA01A, 16700NA01A, VE4/10F1050RNP2614 || Compatible Model: for Nissan TD27 Engine || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 104780-9960, 1047809960, 16700-NA01A, 16700NA01A, VE4/10F1050RNP2614 || Compatible Model: for Nissan TD27 Engine || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

You can express buy:

USD 479.3

14-06-2025

14-06-2025

Diesel injector Fuel Pump 104680-9960 NP-VE4/10F1050RNP2614 16700NA01A For NISSAN TD27

Images:

USD 892.23

[13-May-2025]

USD 409.13

[03-May-2025]

USD 433.07

[19-May-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104780-9960 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1121 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8(100) |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1130 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0020 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1720 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-5920 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0000 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146302-3500 | COMPRESSION SPRING |

| 34B. | [1] | 146302-3400 | COMPRESSION SPRING |

| 34C. | [1] | 146302-3600 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146822-3120 | GOVERNOR COVER |

| 67/1. | [1] | 146805-2120 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146530-0000 | CONTROL LEVER |

| 67/5B. | [1] | 146530-0100 | CONTROL LEVER STAMP 001 |

| 67/5C. | [1] | 146832-1500 | CONTROL LEVER |

| 67/5D. | [1] | 146832-1600 | CONTROL LEVER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146592-0400 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-4000 | CONTROL LEVER |

| 67/12B. | [1] | 146540-4100 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-6900 | FLAT-HEAD SCREW |

| 67/18. | [1] | 146594-0600 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/26. | [1] | 139006-0200 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-4600 | THREADED PIN L=24MM |

| 67/201B. | [1] | 146545-4700 | THREADED PIN L=26MM |

| 67/201C. | [1] | 146545-4800 | THREADED PIN L=28MM |

| 67/202. | [1] | 146598-5000 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 67/204. | [1] | 146545-4500 | DAMPER |

| 95. | [1] | 146861-0120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146976-3800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0400 | CAP |

| 117/1. | [1] | 146877-1020 | PLUG L=5.2 |

| 117/1. | [1] | 146877-1120 | PLUG L=5.3 |

| 117/1. | [1] | 146877-1220 | PLUG L=5.4 |

| 117/1. | [1] | 146877-1320 | PLUG L=5.5 |

| 117/1. | [1] | 146877-1420 | PLUG L=5.6 |

| 117/1. | [1] | 146877-1520 | PLUG L=5.7 |

| 117/1. | [1] | 146877-1620 | PLUG L=5.8 |

| 117/1. | [1] | 146877-1720 | PLUG L=5.9 |

| 117/1. | [1] | 146877-1820 | PLUG L=6.0 |

| 117/1. | [1] | 146877-1920 | PLUG L=6.1 |

| 117/1. | [1] | 146877-2020 | PLUG L=6.2 |

| 117/1. | [1] | 146877-2120 | PLUG L=6.3 |

| 117/1. | [1] | 146877-2220 | PLUG L=6.4 |

| 117/1. | [1] | 146877-2320 | PLUG L=6.5 |

| 117/1. | [1] | 146877-2420 | PLUG L=6.6 |

| 117/1. | [1] | 146877-2520 | PLUG L=6.7 |

| 117/1. | [1] | 146877-2620 | PLUG L=6.8 |

| 120. | [1] | 146879-6920 | RETAINING PIN |

| 122. | [1] | 146580-3900 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0120 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-8320 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 410. | [1] | 014020-6140 | PLAIN WASHER D11.5&6.5 |

| 411. | [1] | 146598-6300 | CAP NUT |

| 412. | [1] | 146598-6400 | ADAPTOR |

| 800S. | [1] | 146009-9220 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-7320 | CAP |

| 836S. | [1] | 146598-7420 | CAP |

| 837S. | [1] | 146598-7310 | CAP |

| 838S. | [1] | 146598-6710 | CAP |

| 906. | [1] | 146984-8400 | NAMEPLATE |

| 907. | [1] | 025803-1640 | WOODRUFF KEY |

Include in #2:

104780-9960

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09W 0FS

f01g09w0fs

ZEXEL

104780-9960

1047809960

NISSAN-DIESEL

16700NA01A

16700na01a

Zexel num

Bosch num

Firm num

Name

104780-9960

F 01G 09W 0FS

16700NA01A NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K

TD27 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

46.9

47.9

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

45.2

42.7

47.7

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

48.1

48.1

48.1

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

46.4

48.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

47.9

44.4

51.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

33.1

30.1

36.1

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

33.1

29.6

36.6

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_04

Pump speed

r/min

1285

1285

1285

Average injection quantity

mm3/st.

15.2

15.2

15.2

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment_02

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55

50

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55

50

60

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

392

363

421

Pressure

kgf/cm2

4

3.7

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

700

700

700

Pressure

kPa

343

304

382

Pressure

kgf/cm2

3.5

3.1

3.9

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

900

900

900

Pressure

kPa

392

353

431

Pressure

kgf/cm2

4

3.6

4.4

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.8

2.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

1.2

0.6

1.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.6

2.4

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.3

2.8

3.7

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

14

10

18

Control lever angle beta

deg.

23

18

28

Test data Ex:

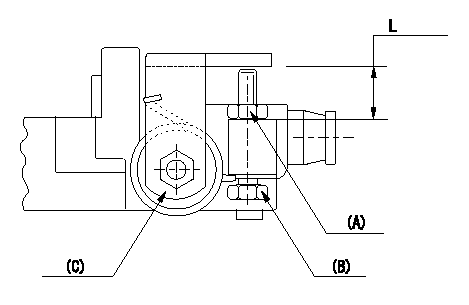

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

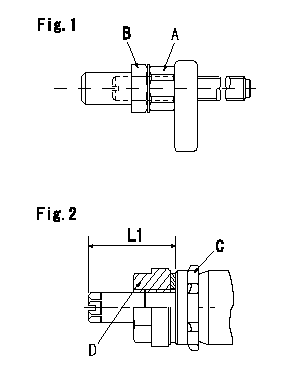

0000001901 TAMPER PROOF

Tamperproof installation procedure

A:Nut

B:Nut

C:Rubber vibration damper

D:Nut

L1:Inspection dimension

Fig. 1 Maximum speed adjusting screw

1) Tighten nut (A) to the torque T1.

2) To prevent nut (A) from turning together, fix (A) using the tool, then tighten nut (B) to torque T1

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (C) and then tighten nut (D) to the torque T2.

----------

L1=23~28mm T1=6~9N-m(0.6~0.9kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm T1=6~9N-m(0.6~0.9kgf-m) T2=7~9N-m(0.7~0.9kgf-m)

----------

L1=23~28mm

Information:

Do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

New Systems, Refilled Systems, and Converted Systems

Perform an S O S coolant analysis (Level 2) at the following maintenance intervals.

Initial 500 service hours

Every Year or every 2000 hours, whichever comes firstPerform this analysis at the interval that occurs first for new systems, for refilled systems, or for converted systems that use Cat ELC (Extended Life Coolant) or use Cat DEAC (Diesel Engine Antifreeze/Coolant). This 500 hour check will also check for any residual cleaner that may have contaminated the system.Recommended Interval for S O S Services Coolant Sample

The following table contains the recommended sampling interval for all coolants that meet Cat EC-1 (Engine Coolant specification - 1). This is also the recommended sampling interval for all conventional heavy-duty coolant/antifreeze.The Level 2 Coolant Analysis should be performed if a problem is suspected or identified.

Table 1

Recommended Interval

Type of Coolant Level 1 Level 2

Cat DEAC

and Conventional Heavy-Duty Coolants Every 250 hours Yearly

Cat ELC

and Commercial EC-1 coolants Optional or every 500 hours Yearly or every 500 hours Note: Check the SCA (Supplemental Coolant Additive) of the conventional coolant at every oil change or at every 250 hours. Perform this check at the interval that occurs first.Refer to your machine OMM for recommendations specific to your machine.S O S Services Coolant Analysis (Level 1)

A coolant analysis (Level 1) is a test of the properties of the coolant.The following properties of the coolant are tested:

Glycol concentration for freeze protection and boil protection

Ability to protect from erosion and corrosion

pH

Conductivity

Visual analysis

Odor analysisThe results are reported, and appropriate recommendations are made.S O S Services Coolant Analysis (Level 2)

A coolant analysis ( Level 2) is a comprehensive chemical evaluation of the coolant. This analysis is also a check of the overall condition of the cooling system.The S O S coolant analysis ( Level 2) has the following features:

Full coolant analysis (Level 1)

Identification of metal corrosion and of contaminants

Identification of buildup of the impurities that cause corrosion

Identification of buildup of the impurities that cause scaling

Determination of the possibility of electrolysis within the cooling system of the engineThe results are reported, and appropriate recommendations are made.For more information on S O S coolant analysis, consult your Caterpillar dealer.

Have questions with 104780-9960?

Group cross 104780-9960 ZEXEL

Nissan-Diesel

104780-9960

F 01G 09W 0FS

16700NA01A

INJECTION-PUMP ASSEMBLY

TD27

TD27