Information injection-pump assembly

BOSCH

9 460 614 800

9460614800

ZEXEL

104780-9800

1047809800

NISSAN-DIESEL

1670074P05

1670074p05

Rating:

Cross reference number

BOSCH

9 460 614 800

9460614800

ZEXEL

104780-9800

1047809800

NISSAN-DIESEL

1670074P05

1670074p05

Zexel num

Bosch num

Firm num

Name

104780-9800

9 460 614 800

1670074P05 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K

TD27 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.3

37.3

43.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

42

39.5

44.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.9

40.4

45.4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

15.7

13.7

17.7

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

34

29.5

38.5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

15.7

12.7

18.7

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

5.1

9.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

4.6

9.6

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57.5

52.5

62.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57.5

52.5

62.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

481

452

510

Pressure

kgf/cm2

4.9

4.6

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

481

442

520

Pressure

kgf/cm2

4.9

4.5

5.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

628

589

667

Pressure

kgf/cm2

6.4

6

6.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.3

4.1

4.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

2

1.6

2.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.3

4

4.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

7.4

6.9

7.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

9

8.5

9.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

3

2.8

3.2

Timer stroke variation dT

mm

1.3

1.3

1.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

3

2.7

3.3

Timer stroke variation dT

mm

1.3

1.3

1.3

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

1.8

1.3

2.3

Timer stroke variation dT

mm

2.5

2.5

2.5

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.36

6.26

6.46

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

Test data Ex:

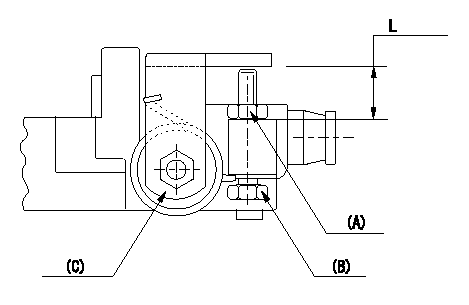

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

Table 4 is an example for using the equation that is in Table 3.

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Have questions with 104780-9800?

Group cross 104780-9800 ZEXEL

Nissan-Diesel

104780-9800

9 460 614 800

1670074P05

INJECTION-PUMP ASSEMBLY

TD27

TD27