Information injection-pump assembly

BOSCH

9 460 614 795

9460614795

ZEXEL

104780-9720

1047809720

NISSAN-DIESEL

167002S519

167002s519

Rating:

Cross reference number

BOSCH

9 460 614 795

9460614795

ZEXEL

104780-9720

1047809720

NISSAN-DIESEL

167002S519

167002s519

Zexel num

Bosch num

Firm num

Name

104780-9720

9 460 614 795

167002S519 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K

TD27 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.3

37.3

43.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

42

39.5

44.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.9

40.4

45.4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

15.7

13.7

17.7

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

34

29.5

38.5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

15.7

12.7

18.7

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

5.1

9.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

4.6

9.6

Difference in delivery

mm3/st.

2.5

2.5

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57.5

52.5

62.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57.5

52.5

62.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

481

452

510

Pressure

kgf/cm2

4.9

4.6

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

481

442

520

Pressure

kgf/cm2

4.9

4.5

5.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

628

589

667

Pressure

kgf/cm2

6.4

6

6.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.3

4.1

4.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke

mm

2

1.6

2.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

4.3

4

4.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

7.4

6.9

7.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

9

8.5

9.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

3

2.8

3.2

Timer stroke variation dT

mm

1.3

1.3

1.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

3

2.7

3.3

Timer stroke variation dT

mm

1.3

1.3

1.3

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

22

19.5

24.5

Timer stroke TA

mm

1.8

1.3

2.3

Timer stroke variation dT

mm

2.5

2.5

2.5

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.36

6.26

6.46

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

Test data Ex:

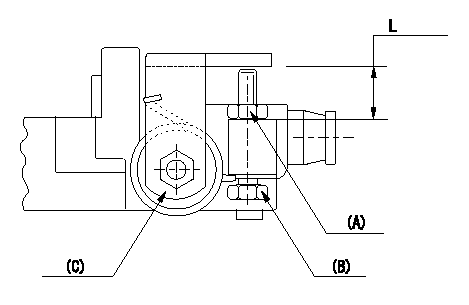

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

Illustration 70 g03402776

Install 8T-5389 Elbow (12) using 238-5081 O-Ring Seal (11) and 228-7092 O-Ring Seal (13)

Illustration 71 g03701313

Install 6V-8636 Connector (17) using 214-7568 O-Ring Seal (16) and 228-7089 O-Ring Seal (18). Install 128-6841 Elbow (15) using 238-5082 O-Ring Seal (19) and 228-7092 O-Ring Seal (14).

Illustration 72 g03701321

Reconnect 209-5526 Hose As (20) to the fuel transfer pump

Illustration 73 g03701349

Install 387-7154 Tube As (21) and 387-7159 Tube As (22).

Illustration 74 g03701355

Install 416-9706 Fuel Tube (24) using 338-8439 Clip (23).

Install the remaining components that were removed during the HEUI pump replacement procedure.Installation Procedure for 511, 521, 522, 532, 541 and 552 Track Feller Bunchers

Table 10

Required parts for 532, 541, 541B , 551, 552, and 552B Track Feller Bunchers

Part Number Description Quantity

384-0607 Unit Injector Hydraulic Pump Gp 1

227-5904 O-Ring Seal 1

6V-7981 Bolt 2

6V-5839 Washer 2

387-7153 Tube As 1

387-7151 Tube As 1

6V-8629 Elbow 1

238-5081 O-Ring Seal 1

228-7092 O-Ring Seal 2

128-6841 Elbow 1

238-5082 O-Ring Seal 1

6V-8636 Connector 2

228-7089 O-Ring Seal 2

214-7568 O-Ring Seal 3

360-3679 Connector Plug 1

6V-3305 O-Ring Adapter 1

214-7567 O-Ring Seal 2

Illustration 75 g03402944

Install 6V-3305 O-Ring Adapter (2) using 214-7567 O-Ring Seal (1). Also install new 214-7567 O-Ring Seal (1) to injection actuation pressure sensor.

Illustration 76 g03402955

Install 384-0607 Unit Injector Hydraulic Pump Gp (4) using 227-5904 O-Ring Seal (3). If necessary, in order to aid in installation, rotate the pump to an 8 o'clock position when looking at the engine from the rear.

Illustration 77 g03402984

Install new 6V-7981 Bolts (5) and 6V-5839 Washers (6). Torque to 55 10 N m (41 7 lb ft)

Illustration 78 g03701359

Install the 6V-8636 Connector (12) using 214-7568 O-Ring Seal (11) and 228-7089 O-Ring Seal (13). Install 360-3679 Connector Plug (10) using 214-7568 O-Ring Seal (11). Install 6V-8629 Elbow (8) using 238-5081 O-Ring Seal (7) and 228-7092 O-Ring Seal (9).

Illustration 79 g03701379

Install 128-6841 Elbow (15) using 238-5082 O-Ring Seal (19) and 228-7092 O-Ring Seal (14). Install 6V-8636 Connector (17) using 214-7568 O-Ring Seal (16) and 228-7089 O-Ring Seal (18).

Illustration 80 g03701406

Install 387-7151 Tube As (21) and 387-7153 Tube As (20).

Install the remaining components that were removed during the HEUI pump replacement procedure.

Have questions with 104780-9720?

Group cross 104780-9720 ZEXEL

Nissan-Diesel

104780-9720

9 460 614 795

167002S519

INJECTION-PUMP ASSEMBLY

TD27

TD27