Information injection-pump assembly

ZEXEL

104780-9260

1047809260

Rating:

Cross reference number

ZEXEL

104780-9260

1047809260

Zexel num

Bosch num

Firm num

Name

104780-9260

INJECTION-PUMP ASSEMBLY

TD27

TD27

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

47.5

45

50

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

39.3

36.3

42.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

47.5

46.5

48.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

44.6

41.6

47.6

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.7

9.7

13.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

38.6

33.6

43.6

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.7

9.2

14.2

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.4

5.4

9.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.4

4.9

9.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

520

481

559

Pressure with S/T ON

kgf/cm2

5.3

4.9

5.7

Pressure with S/T OFF

kPa

432

403

461

Pressure with S/T OFF

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T OFF

kPa

432

393

471

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

559

520

598

Pressure with S/T OFF

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.5

3.1

3.9

Timer stroke with S/T OFF

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

850

850

850

Timer stroke with S/T OFF

mm

0.8

0.3

1.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

3.5

3

4

Timer stroke with S/T OFF

mm

1.9

1.6

2.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.4

3.9

4.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T OFF

mm

6.1

5.6

6.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

30

29.5

30.5

Timer stroke TA

mm

1.2

1

1.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

47.5

46.5

48.5

Timer stroke TA

mm

1.9

1.6

2.2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

30

29

31

Timer stroke TA

mm

1.2

0.9

1.5

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

21

18.5

23.5

Timer stroke TA

mm

0.6

0.1

1.1

Timer stroke variation dT

mm

1.3

1.3

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.8

0.7

0.9

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

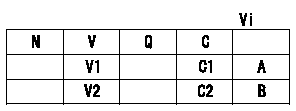

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Adjusting point

B:Confirmation point

C:Position of the control lever

Vi:Applied voltage

V:Potentiometer output voltage

Q:Injection quantity

C1:Idle

C2:Full speed

----------

----------

V1=1.4+-0.03V V2=Above9.5V Vi=10V

----------

----------

V1=1.4+-0.03V V2=Above9.5V Vi=10V

Information:

Use tool (E) in order to cut off the part of rivet (1) that has been peened. Remove rivet (1) from fuel injection control linkage (4) .

Illustration 13 g00702186

The 180-7951 Bushing Assembly Kit (F) Rack Control Shaft (G) Governor Link (4) Fuel Injection Control Linkage (7) 180-7952 Lever Bushing (8) 8L-5832 Hex Nut (9) 9X-8907 Hexagon Button Screw

Use the 180-7951 Bushing Assembly Kit in order to modify the linkage. Insert 9X-8907 Hexagon Button Screw (9) from the 180-7951 Bushing Assembly Kit into fuel injection control linkage (4). Refer to Illustration 13.

Apply 169-5464 Quick Cure Primer apply on the threads of 9X-8907 Hexagon Button Screw (9) and 8L-5832 Hex Nut (8). Allow the primer to dry. The Quick Cure Primer counteracts the effects of the Volatile Corrosion Inhibitor (VCI) paper that was used to package the parts.

Assemble 180-7952 Lever Bushing (7) on 9X-8907 Hexagon Button Screw (9). Refer to Illustration 13.

Apply the 154-9731 Thread Lock Compound on the threads of 9X-8907 Hexagon Button Screw (9) and 8L-5832 Hex Nut (8) .

Illustration 14 g00655322

Place 8L-5832 Hex Nut (8) on 9X-8907 Hexagon Button Screw (9). Tighten 8L-5832 Hex Nut (8) until hex nut (8) is snug. Tighten 8L-5832 Hex Nut (8) for an additional 180 degrees.

Do not let metal chips or pieces of the rivet fall into the engine.

Illustration 15 g00655325

Clean the fuel injection control linkage and clean the surfaces of the cylinder head that are adjacent to the fuel injection control linkage with shop solvent. Remove the towels and remove all debris very carefully.

Install the 180-7956 Clamp Assembly Kit . Refer to the "Installation Of The 180-7956 Clamp Assembly Kit " section of this publication.Installation Of The 180-7956 Clamp Assembly Kit

Note: The 180-7956 Clamp Assembly Kit is used for the former control linkages only.Note: If the 180-7956 Clamp Assembly Kit is installed, refer to ""Modification of the 128-9640 Injector Synchronization Fixture "".The 180-7956 Clamp Assembly Kit may be installed on the fuel injection control linkage. The 180-7956 Clamp Assembly Kit will increase the strength of the joint.

Illustration 16 g00655326

Install 183-9390 Spacer (10) on fuel injection control linkage (4). Refer to Illustration 16.

Apply 169-5464 Quick Cure Primer to the threaded hole in the 180-7954 Clamp (11). Apply 169-5464 Quick Cure Primer to the threads of screw (13). Allow the primer to dry. The Quick Cure Primer counteracts the effects of the Volatile Corrosion Inhibitor (VCI) paper that was used to package the parts.

Apply 154-9731 Thread Lock Compound to the threaded hole in the 180-7954 Clamp (11). Apply 154-9731 Thread Lock Compound to the threads of screw (13) of clamp assembly. Loosely assemble 180-7954 Clamp (11) and 180-7987 Clamp (12) on fuel injection control linkage (4). Refer to Illustration 16. Be sure that the rivet head or bushing (14) is fully engaged into the counterbore of the

Have questions with 104780-9260?

Group cross 104780-9260 ZEXEL

Nissan

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

104780-9260

INJECTION-PUMP ASSEMBLY

TD27

TD27