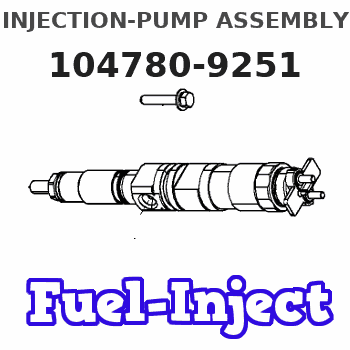

Information injection-pump assembly

ZEXEL

104780-9251

1047809251

Rating:

Cross reference number

ZEXEL

104780-9251

1047809251

Zexel num

Bosch num

Firm num

Name

104780-9251

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.5

44

45

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

39

36

42

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.5

43.5

45.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.2

39.2

45.2

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.7

9.7

13.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

36

31

41

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

11.7

9.2

14.2

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.4

5.4

9.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.4

4.9

9.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

432

403

461

Pressure

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

432

393

471

Pressure

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

559

520

598

Pressure

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

850

850

850

Timer stroke

mm

0.8

0.3

1.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

1.9

1.6

2.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

4.4

3.9

4.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

6.1

5.6

6.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

26

25.5

26.5

Timer stroke TA

mm

1.2

1

1.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.5

43.5

45.5

Timer stroke TA

mm

1.9

1.6

2.2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

26

25

27

Timer stroke TA

mm

1.2

0.9

1.5

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

15

12.5

17.5

Timer stroke TA

mm

0.6

0.1

1.1

Timer stroke variation dT

mm

1.3

1.3

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.8

0.7

0.9

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

Information:

Checking Backpressure with Manometer/Gauge

Remove the plug from the pressure tap coupling located on the manifold immediately after the engine and install a manometer or pressure gauge. Use a gauge with a minimum range of 0 to 20 kpa (0 to 80 inch of H2O).

After completely warming up the engine, run at no load, wide open throttle (W.O.T.) for 2 to 3 minutes. Record the pressure reading while the engine is running at no load, W.O.T. Repeat 2 to 3 times.

If the observed backpressure is less than 10.20 kPa (41 inch of H2O), the DPF can continue to be operated without further maintenance.

If the backpressure is greater than 10.20 kPa (41 inch of H2O) at the time of installation, contact your Caterpillar dealer. If the backpressure is greater than 10.20 kPa (41 inch of H2O) during a maintenance check, contact your Caterpillar dealer. Your Warranty Rights And Obligations

VERIFIED PRODUCT WARRANTY

Caterpillar Inc. warrants the diesel emission control system in the application for which it is sold or leased to be free from defects in design, materials, workmanship, or operation of the diesel emission control system which cause the diesel emission control system to fail to conform to the emission control performance level it was verified to, or to the requirements in the California Code of Regulations, Title 13, Sections 2700 to 2706, and 2710, for the periods of time listed below, provided there has been no abuse, neglect, or improper maintenance of your diesel emission control system, vehicle or equipment, as specified in the owners manuals. Where a warrantable condition exists, this warranty also covers the engine from damage caused by the diesel emission control system, subject to the same exclusions for abuse, neglect or improper maintenance of your vehicle or equipment. Please review your owners manual for other warranty information. Your diesel emission control system may include a core part (e.g., particulate filter, diesel oxidation catalyst, selective catalytic reduction converter) as well as hoses, connectors, a backpressure monitor (if applicable), and other emission-related assemblies. Where a warrantable condition exists, Caterpillar will repair or replace your diesel emission control system at no cost to you including diagnosis, parts, and labor.WARRANTY COVERAGE

For engines used in verified applications, the warranty period will be in years or hours or miles of operation, whichever occurs first, based on the following chart:

Table 1

Engine Type Engine Size Minimum Warranty Period

On-Road Light heavy-duty, 70 to 170 hp, Gross Vehicle Weight Rating (GVWR) less than 19,500 lbs. 5 years or 60,000 miles

Medium heavy-duty, 170 to 250 hp, GVWR from 19,500 lbs. to 33,000 lbs. 5 years or 100,000 miles

Heavy heavy-duty, exceeds 250 hp, GVWR exceeds 33,000 lbs. 5 years or 150,000 miles

Heavy heavy-duty, exceeds 250 hp, GVWR exceeds 33,000 lbs., and trucks are:

1. Typically driven over 100,000 miles per year, and

2. Have less than 300,000 miles on the odometer at the time of installation. 2 years, unlimited miles

Off-Road (includes portable engines) and Stationary Under 25 hp, and for constant speed engines rated under 50 hp with rated speeds

Remove the plug from the pressure tap coupling located on the manifold immediately after the engine and install a manometer or pressure gauge. Use a gauge with a minimum range of 0 to 20 kpa (0 to 80 inch of H2O).

After completely warming up the engine, run at no load, wide open throttle (W.O.T.) for 2 to 3 minutes. Record the pressure reading while the engine is running at no load, W.O.T. Repeat 2 to 3 times.

If the observed backpressure is less than 10.20 kPa (41 inch of H2O), the DPF can continue to be operated without further maintenance.

If the backpressure is greater than 10.20 kPa (41 inch of H2O) at the time of installation, contact your Caterpillar dealer. If the backpressure is greater than 10.20 kPa (41 inch of H2O) during a maintenance check, contact your Caterpillar dealer. Your Warranty Rights And Obligations

VERIFIED PRODUCT WARRANTY

Caterpillar Inc. warrants the diesel emission control system in the application for which it is sold or leased to be free from defects in design, materials, workmanship, or operation of the diesel emission control system which cause the diesel emission control system to fail to conform to the emission control performance level it was verified to, or to the requirements in the California Code of Regulations, Title 13, Sections 2700 to 2706, and 2710, for the periods of time listed below, provided there has been no abuse, neglect, or improper maintenance of your diesel emission control system, vehicle or equipment, as specified in the owners manuals. Where a warrantable condition exists, this warranty also covers the engine from damage caused by the diesel emission control system, subject to the same exclusions for abuse, neglect or improper maintenance of your vehicle or equipment. Please review your owners manual for other warranty information. Your diesel emission control system may include a core part (e.g., particulate filter, diesel oxidation catalyst, selective catalytic reduction converter) as well as hoses, connectors, a backpressure monitor (if applicable), and other emission-related assemblies. Where a warrantable condition exists, Caterpillar will repair or replace your diesel emission control system at no cost to you including diagnosis, parts, and labor.WARRANTY COVERAGE

For engines used in verified applications, the warranty period will be in years or hours or miles of operation, whichever occurs first, based on the following chart:

Table 1

Engine Type Engine Size Minimum Warranty Period

On-Road Light heavy-duty, 70 to 170 hp, Gross Vehicle Weight Rating (GVWR) less than 19,500 lbs. 5 years or 60,000 miles

Medium heavy-duty, 170 to 250 hp, GVWR from 19,500 lbs. to 33,000 lbs. 5 years or 100,000 miles

Heavy heavy-duty, exceeds 250 hp, GVWR exceeds 33,000 lbs. 5 years or 150,000 miles

Heavy heavy-duty, exceeds 250 hp, GVWR exceeds 33,000 lbs., and trucks are:

1. Typically driven over 100,000 miles per year, and

2. Have less than 300,000 miles on the odometer at the time of installation. 2 years, unlimited miles

Off-Road (includes portable engines) and Stationary Under 25 hp, and for constant speed engines rated under 50 hp with rated speeds

Have questions with 104780-9251?

Group cross 104780-9251 ZEXEL

Nissan

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

104780-9251

INJECTION-PUMP ASSEMBLY