Information injection-pump assembly

BOSCH

9 460 613 406

9460613406

ZEXEL

104780-9180

1047809180

NISSAN-DIESEL

1670040K10

1670040k10

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

ASGIHVAC Material: made of high-quality materials, with the characteristics of corrosion resistance and high strength. || Quality: manufactured according to strict quality control standards, not easy to damage, long service life. || Performance: stable performance, high reliability and good performance, specially designed for silent operation. || Appearance: the appearance is novel and beautiful, and the installation is convenient. || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

ASGIHVAC Material: made of high-quality materials, with the characteristics of corrosion resistance and high strength. || Quality: manufactured according to strict quality control standards, not easy to damage, long service life. || Performance: stable performance, high reliability and good performance, specially designed for silent operation. || Appearance: the appearance is novel and beautiful, and the installation is convenient. || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

Diesel Fuel Injection Pump 104780-9851, 16700-40K10, 16700-NA00E, Compatible with Nissan TD27 Diesel Engine, High Pressure Precision Pump Assembly(104780-9851)

Adfghjk Diesel Fuel Injection Pump (Model: 104780-9851 , 16700-40K10 , 16700-NA00E): Compatible with Nissan TD27 diesel engine design, high pressure injection technology optimizes fuel efficiency and reduces fuel consumption and emissions. || Precise compatibility: Strictly matching the Nissan TD27 original specification, seamless installation without modifying the engine structure. || Upgraded Durability: Hardened alloy core and ceramic seals increase wear resistance by 40% to adapt to high load conditions. || Stable Fuel Supply: Intelligent pressure regulation system ensures even fuel atomization, reducing engine knock and power fluctuation. || Ready-to-Use: The complete pump assembly includes sealing ring and fixing bolt, which saves maintenance time and reduces the cost of secondary purchase.

Adfghjk Diesel Fuel Injection Pump (Model: 104780-9851 , 16700-40K10 , 16700-NA00E): Compatible with Nissan TD27 diesel engine design, high pressure injection technology optimizes fuel efficiency and reduces fuel consumption and emissions. || Precise compatibility: Strictly matching the Nissan TD27 original specification, seamless installation without modifying the engine structure. || Upgraded Durability: Hardened alloy core and ceramic seals increase wear resistance by 40% to adapt to high load conditions. || Stable Fuel Supply: Intelligent pressure regulation system ensures even fuel atomization, reducing engine knock and power fluctuation. || Ready-to-Use: The complete pump assembly includes sealing ring and fixing bolt, which saves maintenance time and reduces the cost of secondary purchase.

Diesel Fuel Injection Pump 104680-9851, Compatible with Nissan TD27 Engine, Industrial-Grade Corrosion-Resistant, Precision Replacement for 104780-9180 VE4 10F1150RNP2171(104780-9180)

Adfghjk Diesel Injection Pump 104680-9851, compatible with Nissan TD27, ±0.025mm OEM tolerance ensures ECU compatibility and error free operation. || Industrial Corrosion Resistance: Zinc-nickel alloy housing and ceramic coated piston tested to 2200hr ASTM B117 for 3.2 times the life in high sulfur diesel environments. || 1700bar High Pressure Injection: ≤1.4% difference in dynamic flow rate optimizes combustion, reduces soot by 42% and meets Euro IV standards. || Quiet full-load performance: Hydraulic equalizers and vibration damping mounts reduce noise to 45 dB, ensuring reliability in commercial vehicles. || Calibration-Free Installation: Pre-assembled OEM seals and TD27 kits can be replaced in 20 minutes without diagnostics.

Adfghjk Diesel Injection Pump 104680-9851, compatible with Nissan TD27, ±0.025mm OEM tolerance ensures ECU compatibility and error free operation. || Industrial Corrosion Resistance: Zinc-nickel alloy housing and ceramic coated piston tested to 2200hr ASTM B117 for 3.2 times the life in high sulfur diesel environments. || 1700bar High Pressure Injection: ≤1.4% difference in dynamic flow rate optimizes combustion, reduces soot by 42% and meets Euro IV standards. || Quiet full-load performance: Hydraulic equalizers and vibration damping mounts reduce noise to 45 dB, ensuring reliability in commercial vehicles. || Calibration-Free Installation: Pre-assembled OEM seals and TD27 kits can be replaced in 20 minutes without diagnostics.

You can express buy:

USD 406.7

14-06-2025

14-06-2025

Diesel Fuel Injection Pump 104680-9851 10F1150RNP2171 104780-9180 for Forklift Truck Pickup TD27 Engine

Images:

USD 411.32

[13-May-2025]

USD 393.14

[13-May-2025]

USD 439.92

[14-Jun-2025]

USD 438.1

[14-Jun-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104780-9180 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104680-9180 |

| 3. | NUMBER PLATE | 146982-0900 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1121 |

| 8. | Nozzle and Holder | 16600-43G03 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1130 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0020 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-1720 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0000 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-3600 | COMPRESSION SPRING |

| 34B. | [1] | 146302-3500 | COMPRESSION SPRING |

| 34C. | [1] | 146302-3700 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146820-8620 | GOVERNOR COVER |

| 67/1. | [1] | 146805-2120 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/6. | [1] | 014110-6440 | LOCKING WASHER |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146592-0400 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER D14&10.1T1.50 |

| 67/12. | [1] | 146540-4000 | CONTROL LEVER |

| 67/12B. | [1] | 146540-4100 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/25. | [2] | 013020-6040 | UNION NUT M6P1H5 |

| 67/25. | [2] | 013020-6040 | UNION NUT M6P1H5 |

| 67/26. | [1] | 139006-0200 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 72. | [1] | 146831-1120 | CONTROL LEVER |

| 72B. | [1] | 146831-1220 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146861-0120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER D34&13T1.0 |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 120. | [1] | 146579-2720 | RETAINING PIN |

| 120B. | [1] | 146579-2820 | RETAINING PIN |

| 122. | [1] | 146580-3900 | GOVERNOR SPRING |

| 123. | [3] | 139106-0200 | FLAT-HEAD SCREW |

| 124. | [1] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0120 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146592-1300 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-7200 | COILED SPRING |

| 230. | [1] | 146933-1420 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-6120 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 321. | [1] | 146932-2600 | PLATE |

| 800S. | [1] | 146009-9220 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 906. | [1] | 146982-0900 | NAMEPLATE |

Include in #2:

104780-9180

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 406

9460613406

ZEXEL

104780-9180

1047809180

NISSAN-DIESEL

1670040K10

1670040k10

Zexel num

Bosch num

Firm num

Name

104780-9180

9 460 613 406

1670040K10 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K

TD27 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

46.9

47.9

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

43.4

43.4

43.4

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

45.2

43.2

47.2

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

48.1

48.1

48.1

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

46.4

48.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

47.2

43.7

50.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

15.4

12.4

18.4

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1430

1430

1430

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

15.4

11.9

18.9

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

295

295

295

Average injection quantity

mm3/st.

42.5

37.2

47.8

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55

50

60

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55

50

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

392

363

421

Pressure

kgf/cm2

4

3.7

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

392

353

431

Pressure

kgf/cm2

4

3.6

4.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1100

1100

1100

Pressure

kPa

432

393

471

Pressure

kgf/cm2

4.4

4

4.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.8

2.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.6

2.4

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.9

2.3

3.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.3

2.8

3.7

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

33

28

38

Test data Ex:

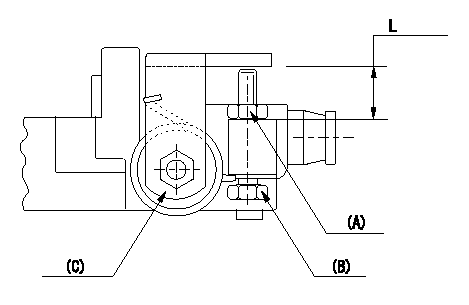

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

2301A Electric Governor Control

The 2301A Electric Governor Control activates all of the components that are in the electric protection system. The components are activated in the same manner when the nonelectric governor is used. One difference exists in the main circuit. The fuel shutoff solenoid (FSOS) (line 43) is not used.When the electric governor control is used, the engine must run in a normal condition in order for the electric circuit to operate in the manner that is described below.

Current flows from the terminals (TS-28) (line 43) and (TS-31) (line 44), which are located on the terminal strip in the junction box.

Current from terminals (TS-28) (line 43) and (TS-31) (line 44) flows through the preregulator (PR) (line 48) or the fuse (F4) to the electric governor control.

When the engine flywheel is rotating, the current also flows through the electric governor actuator (EGA) (line 52). When a fault in the system causes the current to energize the slave relay (SR1), the following events occur in the electric circuit in order to stop the engine.

The slave relay (SR1) opens across the contacts (SR1-30) and (SR1-87a) (line 45). The relay closes across the contacts (SR1-30) and (SR1-87) (line 43).

When the circuit opens across contacts (SR1-30) and (SR1-87a), the current is stopped to the electric governor control.

Current to the electric governor actuator (EGA) is also stopped.

The mechanical spring load in the electric governor actuator (EGA) will now move the fuel control rod in order to stop fuel flow to the engine. Note: With the exception of the differences that are described in this section of the manual, all of the fault circuits in the electric protection system are identical for the 2301A Electric Governor Control and for the nonelectric governor control.

Illustration 5 g00292615

Junction Box Wiring for ETR protection system with OP, WT, and OS that does not require

Have questions with 104780-9180?

Group cross 104780-9180 ZEXEL

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

104780-9180

9 460 613 406

1670040K10

INJECTION-PUMP ASSEMBLY

TD27

TD27