Information injection-pump assembly

BOSCH

9 460 614 783

9460614783

ZEXEL

104780-9172

1047809172

NISSAN-DIESEL

167006T079

167006t079

Rating:

Cross reference number

BOSCH

9 460 614 783

9460614783

ZEXEL

104780-9172

1047809172

NISSAN-DIESEL

167006T079

167006t079

Zexel num

Bosch num

Firm num

Name

104780-9172

9 460 614 783

167006T079 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

TD27 K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.8

44.3

45.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.8

39.3

44.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.8

43.8

45.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

44.5

41.5

47.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

450

320

580

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1300

1300

1300

Pressure with S/T ON

kPa

559

520

598

Pressure with S/T ON

kgf/cm2

5.7

5.3

6.1

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1300

1300

1300

Pressure with S/T OFF

kPa

471

432

510

Pressure with S/T OFF

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

559

520

598

Pressure with S/T OFF

kgf/cm2

5.7

5.3

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

4.2

3.8

4.6

Timer stroke with S/T OFF

mm

2.3

2.1

2.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T OFF

mm

1.4

0.9

1.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

4.2

3.7

4.7

Timer stroke with S/T OFF

mm

2.3

2

2.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.1

3.6

4.6

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T OFF

mm

6.2

5.7

6.6

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

27.8

27.3

28.3

Timer stroke TA

mm

1.7

1.5

1.9

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

27.8

26.8

28.8

Timer stroke TA

mm

1.7

1.4

2

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

16.8

14.3

19.3

Timer stroke TA

mm

1.1

0.6

1.6

Timer stroke variation dT

mm

1.2

1.2

1.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

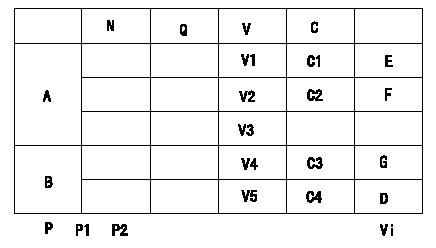

Note: Potentiometer (P/M) adjustment method

Substitute the actual measurement of the angle a of each I/P in the following formula and determine the P/M output adjustment y (V).

When the angle a <= c: y = 7.23

When c < angle a < d: y = 7.23+( angle a -33) x 0.133

When d <alpha <e: y=7.97

Reference: Idle position and full speed position output voltages are V6 (idle) and V7 (full speed).

The switch voltage specification is the value when the idle lever position is V8.

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C1:Full-speed

C2:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

----------

a=MEASURE c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V V8=0V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=0.82+-0.8V V5=3.2+-0.8V C3=4.9+5.3-4.8deg C4=19.4+-5.0deg Vi=10V P1=-kPa P2=-mmHg

----------

a=MEASURE c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V V8=0V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=0.82+-0.8V V5=3.2+-0.8V C3=4.9+5.3-4.8deg C4=19.4+-5.0deg Vi=10V P1=-kPa P2=-mmHg

Information:

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

2301A Electric Governor Control

The 2301A Electric Governor Control activates all of the components that are in the electric protection system. The components are activated in the same manner when the nonelectric governor is used. One difference exists in the main circuit. The fuel shutoff solenoid (FSOS) (line 43) is not used.When the electric governor control is used, the engine must run in a normal condition in order for the electric circuit to operate in the manner that is described below.

Current flows from the terminals (TS-28) (line 43) and (TS-31) (line 44), which are located on the terminal strip in the junction box.

Current from terminals (TS-28) (line 43) and (TS-31) (line 44) flows through the preregulator (PR) (line 48) or the fuse (F4) to the electric governor control.

When the engine flywheel is rotating, the current also flows through the electric governor actuator (EGA) (line 52). When a fault in the system causes the current to energize the slave relay (SR1), the following events occur in the electric circuit in order to stop the engine.

The slave relay (SR1) opens across the contacts (SR1-30) and (SR1-87a) (line 45). The relay closes across the contacts (SR1-30) and (SR1-87) (line 43).

When the circuit opens across contacts (SR1-30) and (SR1-87a), the current is stopped to the electric governor control.

Current to the electric governor actuator (EGA) is also stopped.

The mechanical spring load in the electric governor actuator (EGA) will now move the fuel control rod in order to stop fuel flow to the engine. Note: With the exception of the differences that are described in this section of the manual, all of the fault circuits in the electric protection system are identical for the 2301A Electric Governor Control and for the nonelectric governor control.

Illustration 3 g00292636

Junction Box Wiring for ETR protection

Have questions with 104780-9172?

Group cross 104780-9172 ZEXEL

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

104780-9172

9 460 614 783

167006T079

INJECTION-PUMP ASSEMBLY

TD27

TD27