Information injection-pump assembly

ZEXEL

104780-9171

1047809171

NISSAN

167006T079

167006t079

Rating:

Cross reference number

ZEXEL

104780-9171

1047809171

NISSAN

167006T079

167006t079

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44

43.5

44.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.8

38.3

43.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44

43

45

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

45.1

42.1

48.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

450

320

580

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1300

1300

1300

Pressure with S/T ON

kPa

549

510

588

Pressure with S/T ON

kgf/cm2

5.6

5.2

6

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1300

1300

1300

Pressure with S/T OFF

kPa

471

432

510

Pressure with S/T OFF

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_03

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

647

608

686

Pressure with S/T OFF

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

4.4

4

4.8

Timer stroke with S/T OFF

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T OFF

mm

1.9

1.4

2.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

4.4

3.9

4.9

Timer stroke with S/T OFF

mm

2.9

2.6

3.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

2150

2150

2150

Timer stroke with S/T OFF

mm

6.6

6

7

Oil temperature

degC

52

50

54

_05

Pump speed

r/min

2500

2500

2500

Timer stroke with S/T OFF

mm

6.6

6.1

7

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

30

29.5

30.5

Timer stroke TA

mm

2.5

2.5

2.5

Timer stroke variation dT

mm

0.4

0.2

0.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

30

29

31

Timer stroke variation dT

mm

0.4

0.1

0.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

18

15.5

20.5

Timer stroke variation dT

mm

1.2

0.8

1.6

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

36

31

41

Test data Ex:

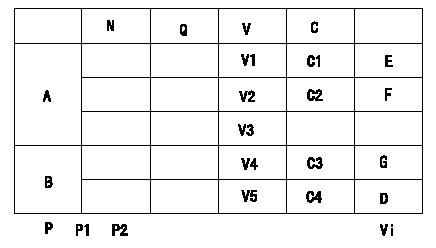

0000001801 POTENTIOMETER ADJUSTMENT

Note: Potentiometer (P/M) adjustment method

Substitute the actual measurement of the angle a of each I/P in the following formula and determine the P/M output adjustment y (V).

When the angle a <= c: y = 7.23

When c < angle a < d: y = 7.23+( angle a -33) x 0.133

When d <alpha <e: y=7.97

Reference: Idle position and full speed position output voltages are V6 (idle) and V7 (full speed).

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C1:Full-speed

C2:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

----------

a=-deg c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

----------

a=-deg c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

Information:

Problem 2

The engine does not crank.

Check the engine mounted start switch (EMSS).

Ensure that the emergency stop switch (ES) has been reset.

Place a switch across the terminals of the EMSS.

Close the switch momentarily, but do not start the engine.

Remove the switch when the test is completed. Result

The engine cranks.The EMSS is faulty or the circuit breaker (CB2) must be reset.

The engine does not crank.Go to Step 3.

Check the start/stop switch.

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-21) and (TS-26) of the junction box.

Close the switch momentarily, but do not start the engine.

Disconnect the switch after the test is completed. Results

The engine cranks.The start/stop switch is faulty or the wiring to the switch is faulty. Replace the switch or repair the wiring. The circuit breaker (CB2) may need to be reset.

The engine does not crank.Go to Step 3.

Check the emergency stop switch (ES).

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-26) and (TS-24) of the junction box.

Close the switch momentarily but do not start the engine.

Disconnect the switch after the test is completed. Result

The engine cranks.The emergency stop switch (ES) is faulty.

The engine does not crank.Reset the circuit breaker (CB5) and repeat Step 3. If the engine does not crank go to Step 4.

Check the components of the starting system.

Check the voltage at terminal (TS-24) of the junction box. Result

The voltage is low. Low voltage is between 1 volt and 20 volts.Charge the battery or repair the loose connections between the battery cable terminal and the battery. STOP.

The voltage is above 20 volts.The magnetic switch (MS), the pinion solenoid (PS), or the starting motor (SM) is faulty. The circuit breaker (CB2) may need to be reset. Reset the circuit breaker and repair the component that is faulty.

The voltage is zero (less than 1 volt).The circuit breaker (CB5) is being overloaded or the circuit breaker is faulty. Repair the short circuit or replace the circuit breaker. STOP.Problem 3

The engine starts and shutdown occurs immediately, or engine cranking terminates.

Check the protection switches.

Measure the voltage at terminal (SR2-30) while you crank the engine. Result

The voltage is above 10 volts while you crank the engine. The voltage then decreases to zero when the engine shuts down.The emergency stop switch (ES), the water temperature contactor switch (WTS), and the start/stop switch are opening. Check the start/stop switch first. The switch may be open across the common pair of contacts for the START/RUN switch when the switch is in the START position. The switch may also be open when the switch is released from the START position. Go to Step 7 of "Problem 1".

The voltage is above 10 volts at all times.The diode (D2) is faulty or there is a short across the diode circuit. The engine oil pressure switch (OPS1) may also have an intermittent short in the switch or in the connection. Refer

The engine does not crank.

Check the engine mounted start switch (EMSS).

Ensure that the emergency stop switch (ES) has been reset.

Place a switch across the terminals of the EMSS.

Close the switch momentarily, but do not start the engine.

Remove the switch when the test is completed. Result

The engine cranks.The EMSS is faulty or the circuit breaker (CB2) must be reset.

The engine does not crank.Go to Step 3.

Check the start/stop switch.

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-21) and (TS-26) of the junction box.

Close the switch momentarily, but do not start the engine.

Disconnect the switch after the test is completed. Results

The engine cranks.The start/stop switch is faulty or the wiring to the switch is faulty. Replace the switch or repair the wiring. The circuit breaker (CB2) may need to be reset.

The engine does not crank.Go to Step 3.

Check the emergency stop switch (ES).

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-26) and (TS-24) of the junction box.

Close the switch momentarily but do not start the engine.

Disconnect the switch after the test is completed. Result

The engine cranks.The emergency stop switch (ES) is faulty.

The engine does not crank.Reset the circuit breaker (CB5) and repeat Step 3. If the engine does not crank go to Step 4.

Check the components of the starting system.

Check the voltage at terminal (TS-24) of the junction box. Result

The voltage is low. Low voltage is between 1 volt and 20 volts.Charge the battery or repair the loose connections between the battery cable terminal and the battery. STOP.

The voltage is above 20 volts.The magnetic switch (MS), the pinion solenoid (PS), or the starting motor (SM) is faulty. The circuit breaker (CB2) may need to be reset. Reset the circuit breaker and repair the component that is faulty.

The voltage is zero (less than 1 volt).The circuit breaker (CB5) is being overloaded or the circuit breaker is faulty. Repair the short circuit or replace the circuit breaker. STOP.Problem 3

The engine starts and shutdown occurs immediately, or engine cranking terminates.

Check the protection switches.

Measure the voltage at terminal (SR2-30) while you crank the engine. Result

The voltage is above 10 volts while you crank the engine. The voltage then decreases to zero when the engine shuts down.The emergency stop switch (ES), the water temperature contactor switch (WTS), and the start/stop switch are opening. Check the start/stop switch first. The switch may be open across the common pair of contacts for the START/RUN switch when the switch is in the START position. The switch may also be open when the switch is released from the START position. Go to Step 7 of "Problem 1".

The voltage is above 10 volts at all times.The diode (D2) is faulty or there is a short across the diode circuit. The engine oil pressure switch (OPS1) may also have an intermittent short in the switch or in the connection. Refer