Information injection-pump assembly

ZEXEL

104780-9170

1047809170

Rating:

Cross reference number

ZEXEL

104780-9170

1047809170

Zexel num

Bosch num

Firm num

Name

104780-9170

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44

43.5

44.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.8

38.3

43.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44

43

45

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

46.7

43.7

49.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.9

12.9

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

8.4

13.4

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.7

9.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.7

5.2

10.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

450

320

580

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1300

1300

1300

Pressure with S/T ON

kPa

549

510

588

Pressure with S/T ON

kgf/cm2

5.6

5.2

6

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1300

1300

1300

Pressure with S/T OFF

kPa

471

432

510

Pressure with S/T OFF

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_03

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

647

608

686

Pressure with S/T OFF

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

3.6

3.2

4

Timer stroke with S/T OFF

mm

2.1

1.9

2.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T OFF

mm

1.1

0.6

1.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Timer stroke with S/T ON

mm

3.6

3.1

4.1

Timer stroke with S/T OFF

mm

2.1

1.8

2.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

2150

2150

2150

Timer stroke with S/T OFF

mm

5.6

5

6.2

Oil temperature

degC

52

50

54

_05

Pump speed

r/min

2500

2500

2500

Timer stroke with S/T OFF

mm

6.1

5.6

6.5

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

25.5

25

26

Timer stroke TA

mm

1.8

1.8

1.8

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

25.5

24.5

26.5

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

17

14.5

19.5

Timer stroke variation dT

mm

0.9

0.5

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

36

31

41

Test data Ex:

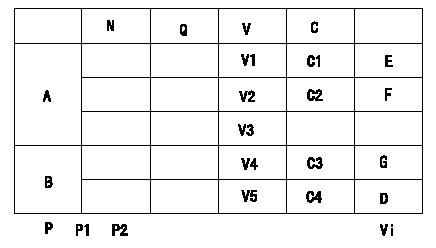

0000001801 POTENTIOMETER ADJUSTMENT

Note: Potentiometer (P/M) adjustment method

Substitute the actual measurement of the angle a of each I/P in the following formula and determine the P/M output adjustment y (V).

When the angle a <= c: y = 7.23

When c < angle a < d: y = 7.23+( angle a -33) x 0.133

When d <alpha <e: y=7.97

Reference: Idle position and full speed position output voltages are V6 (idle) and V7 (full speed).

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C1:Full-speed

C2:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

----------

a=-deg c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

----------

a=-deg c=33deg d=39deg e=-deg P1=-kPa P2=-mmHg V6=1.6+-0.6V V7=7.6+-0.4V

----------

V1=a+-0.03V V2=1.6+-0.6V V3=-V V4=-V V5=-V C3=0.1~10.2deg C4=(19.4)deg Vi=10V P1=-kPa P2=-mmHg

Information:

Problem 4

The starting motor remains engaged or the starting motor continues to run after the engine is running.

Check the components of the starting circuit.

Measure the voltages at terminal (TS-26) of the junction box and at terminal (ESS-12) of the electronic speed switch while the engine is running. Result

The voltage at both terminals is zero volts.The problem is in the starting motor (SM), the pinion solenoid (PS), or the magnetic switch (MS). Repair the faulty component. STOP.

The voltage at terminal (ESS-12) is between 15 volts and 32 volts. The voltage at terminal (TS-26) is above 15 volts or below 15 volts but not zero volts.The contacts for the crank terminate (CT) switch of the electronic speed switch (ESS) do not open. Refer to Testing and Adjusting, "Crank Terminate Speed Calibration". If the ESS is not faulty, check diode (D3). Refer to Testing and Adjusting, "Diode Test".

The voltage at both terminals is between 15 volts and 32 volts.The voltage at the terminals is greater than zero volts. During the normal operation of the start/stop switch, the start/stop switch opens across the contacts of the START position. Also, the start/stop switch closes across the contacts of the RUN position. The switch closes when the toggle or the lever of the switch moves from the START position to the RUN position. Repair the switch if the voltage is zero.

The voltage at terminal (ESS-12) is not zero.The CT contacts of the ESS are not opening. Refer to Testing and Adjusting, "Crank Terminate Speed Calibration".Problem 5

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the overspeed setting on the electronic speed switch (ESS).

Observe the indicator lamp on the ESS.

Reset the air shutoff lever, if equipped. Result

The indicator lamp on the ESS is turned on.Overspeed is indicated as the cause of the engine shutdown. Press the "RESET" button of the ESS. Find the cause of the overspeed. Refer to Testing and Adjusting, "Overspeed Verification Test" and Testing and Adjusting, "Overspeed Calibration". If the overspeed is adjusted properly and the problem persists, check the shielded cable. Only the shield should be connected to terminal 2 on the ESS. STOP.

The indicator lamp is turned off.Go to Step 2.

Check the oil pressure switches.

Connect a jumper between terminals (TS-9) and (TS-14) of the junction box.

Start the engine. Result

The engine starts and the engine runs.The problem is in the oil pressure switches. Go to Step 7 of "Problem 3".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 3.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".Note: If the water temperature contactor switch causes overheating go to Step 8 of "Problem 1". If the water temperature contactor switch is not the problem, go to Step 1of "Problem 1".

Check the slave relay (SR1).

Disconnect the jumper from terminals (TS-9) and (TD-14).

Connect a jumper between terminals (TS-14) and

The starting motor remains engaged or the starting motor continues to run after the engine is running.

Check the components of the starting circuit.

Measure the voltages at terminal (TS-26) of the junction box and at terminal (ESS-12) of the electronic speed switch while the engine is running. Result

The voltage at both terminals is zero volts.The problem is in the starting motor (SM), the pinion solenoid (PS), or the magnetic switch (MS). Repair the faulty component. STOP.

The voltage at terminal (ESS-12) is between 15 volts and 32 volts. The voltage at terminal (TS-26) is above 15 volts or below 15 volts but not zero volts.The contacts for the crank terminate (CT) switch of the electronic speed switch (ESS) do not open. Refer to Testing and Adjusting, "Crank Terminate Speed Calibration". If the ESS is not faulty, check diode (D3). Refer to Testing and Adjusting, "Diode Test".

The voltage at both terminals is between 15 volts and 32 volts.The voltage at the terminals is greater than zero volts. During the normal operation of the start/stop switch, the start/stop switch opens across the contacts of the START position. Also, the start/stop switch closes across the contacts of the RUN position. The switch closes when the toggle or the lever of the switch moves from the START position to the RUN position. Repair the switch if the voltage is zero.

The voltage at terminal (ESS-12) is not zero.The CT contacts of the ESS are not opening. Refer to Testing and Adjusting, "Crank Terminate Speed Calibration".Problem 5

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the overspeed setting on the electronic speed switch (ESS).

Observe the indicator lamp on the ESS.

Reset the air shutoff lever, if equipped. Result

The indicator lamp on the ESS is turned on.Overspeed is indicated as the cause of the engine shutdown. Press the "RESET" button of the ESS. Find the cause of the overspeed. Refer to Testing and Adjusting, "Overspeed Verification Test" and Testing and Adjusting, "Overspeed Calibration". If the overspeed is adjusted properly and the problem persists, check the shielded cable. Only the shield should be connected to terminal 2 on the ESS. STOP.

The indicator lamp is turned off.Go to Step 2.

Check the oil pressure switches.

Connect a jumper between terminals (TS-9) and (TS-14) of the junction box.

Start the engine. Result

The engine starts and the engine runs.The problem is in the oil pressure switches. Go to Step 7 of "Problem 3".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 3.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".Note: If the water temperature contactor switch causes overheating go to Step 8 of "Problem 1". If the water temperature contactor switch is not the problem, go to Step 1of "Problem 1".

Check the slave relay (SR1).

Disconnect the jumper from terminals (TS-9) and (TD-14).

Connect a jumper between terminals (TS-14) and

Have questions with 104780-9170?

Group cross 104780-9170 ZEXEL

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

104780-9170

INJECTION-PUMP ASSEMBLY