Information injection-pump assembly

BOSCH

9 460 614 780

9460614780

ZEXEL

104780-9090

1047809090

NISSAN-DIESEL

1670084K02

1670084k02

Rating:

Cross reference number

BOSCH

9 460 614 780

9460614780

ZEXEL

104780-9090

1047809090

NISSAN-DIESEL

1670084K02

1670084k02

Zexel num

Bosch num

Firm num

Name

104780-9090

9 460 614 780

1670084K02 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD27 K

TD27 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

49

48.5

49.5

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

41.8

41.8

41.8

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

43.3

43.3

43.3

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

46.5

46.5

46.5

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

47.4

47.4

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

49

48

50

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

48.1

44.6

51.6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

15.5

12.5

18.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1650

1650

1650

Average injection quantity

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

15.5

12

19

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

55

65

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

55

65

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

392

363

421

Pressure

kgf/cm2

4

3.7

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

392

353

431

Pressure

kgf/cm2

4

3.6

4.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1100

1100

1100

Pressure

kPa

432

393

471

Pressure

kgf/cm2

4.4

4

4.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.8

2.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2

1.6

2.4

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.9

2.3

3.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.3

2.8

3.7

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

35

30

40

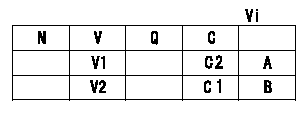

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Adjusting point

B:Confirmation point

C:Position of the control lever

Vi:Applied voltage

V:Potentiometer output voltage

Q:Injection quantity

C1:Idle

C2:Full speed

----------

----------

V1=7.5+-0.03V V2=(1.6)V Vi=10V

----------

----------

V1=7.5+-0.03V V2=(1.6)V Vi=10V

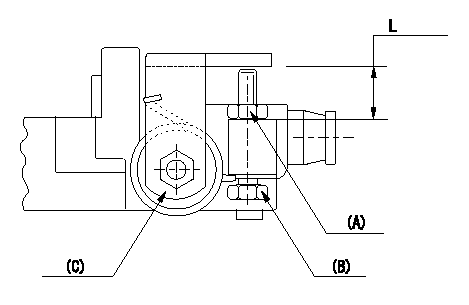

0000001901 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

Illustration 39 g00367353

Set the drive speed to "Col 4". Place a straight edge across the opening in the shutdown rod and the shutdown rod nut (F). Use a 7/16 inch open end wrench in order to turn the shutdown rod nut (F) counterclockwise until the governor begins to shut down. Once the governor begins to shut down, turn the nut clockwise one full turn.Adjustment Of The Shutdown Device

Note: The electric shutdown device and the pressure shutdown device should be checked prior to the installation, after the installation, and at 1000 hour intervals thereafter.

Failure to test, inspect and maintain these items could result in faulty operation and possible severe engine damage if an emergency shutdown situation occurs.

The electric shutdown is either an Energize-To-Shutoff (ETS) or an Energize-To-Run (ETR). Identify the type of shutdown device in your governor, and make a note of the type of shutdown device.

Visually inspect the pressure shutdown components for signs of burrs, nicks, scoring and/or wear. Repair the components if evidence of a problem exists. Inspect the pressure shutdown gasket. Determine if the gasket is reusable. If necessary, replace the gasket.

Illustration 40 g00367319

(F) Shutdown Rod Nut. (J) Shutdown Rod. (II) Solenoid. (JJ) Jam Nut. (KK) Set Screw. (LL) Shutdown Plunger. (MM) Solenoid Plunger. (NN) Pivot Pin. (PP) Shutdown Lever.

Visually inspect the electric shutdown device and determine if there is any component wear. If the shutdown is an ETS version, pay particular attention to the connection of the shutdown solenoid's plunger and the shutdown lever's link pin.If there is evidence of wear, replace the solenoid. Inspect the gasket on the electric shutdown. Determine if the gasket is reusable. If necessary, replace the gasket.Check the size of spacer on the solenoid plunger in the electric shutdown. Refer to the Service Magazine Article November 19,, "Field Replacement of Spacer to Correct Possible Sticking in Woodward 3161 Governor Electric Shutoff Group".Adjustment Of The Electric Shutdown Solenoid

Energize-To-Shutoff (ETS)

Place the housing of the electric shutdown in a vise. Use copper jaws or shop towels in order to protect the sides of the aluminum die cast housing. Do NOT excessively tighten the vise.Loosen the jam nut (JJ) that holds the solenoid in the electric shutdown's housing. Remove the solenoid coil (II) in order to expose the shutdown plunger (MM) .Note: Loctite 222 is used on the threads of the solenoid coil during manufacturing. In addition, the jam nut is tightened to a torque of 75 N m (55.5 lb ft).

Carefully clean any dirt, metal filings or metal chips from the solenoid plunger and from the cavity in the solenoid coil. Turn the jam nut on the solenoid coil so that the nut will not interfere with the adjustment of the solenoid coil. Reinstall the solenoid coil in the electric shutdown's housing by turning the coil four times.

Hold the housing and the gasket on a

Have questions with 104780-9090?

Group cross 104780-9090 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Nissan

Nissan-Diesel

Dpico

Nissan-Diesel

Nissan

Nissan-Diesel

104780-9090

9 460 614 780

1670084K02

INJECTION-PUMP ASSEMBLY

TD27

TD27