Information injection-pump assembly

BOSCH

9 460 613 504

9460613504

ZEXEL

104780-9016

1047809016

NISSAN-DIESEL

167003S900

167003s900

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104780-9016 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104680-9016 |

| 3. | NUMBER PLATE | 146982-6500 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1221 |

| 8. | Nozzle and Holder | 16600-63G01 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6320 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2700 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2500 | COMPRESSION SPRING |

| 34D. | [1] | 146312-2800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-3520 | DELIVERY-VALVE ASSEMBLY VE35 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146753-1320 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146805-3320 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-1700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-1400 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-3800 | COILED SPRING |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-4620 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/55. | [2] | 146620-9800 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0200 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146935-2300 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/99. | [2] | 010006-1070 | BLEEDER SCREW |

| 67/100. | [1] | 146935-2821 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146810-7520 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146536-5321 | CONTROL LEVER |

| 72B. | [1] | 146536-5421 | CONTROL LEVER |

| 72C. | [1] | 146830-6721 | CONTROL LEVER |

| 72D. | [1] | 146830-6821 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146871-1320 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146976-1100 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-5820 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-4901 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146592-6100 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-6000 | COILED SPRING |

| 221. | [1] | 146927-2620 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 224. | [1] | 146927-2700 | BRACKET |

| 230. | [1] | 146934-7920 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-6620 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146669-5420 | INLET UNION |

| 247. | [1] | 146669-5420 | INLET UNION |

| 309. | [1] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146685-0420 | POTENTCIOMETER |

| 310/2. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/3. | [1] | 146620-1500 | FLAT-HEAD SCREW |

| 310/4. | [1] | 013020-6040 | UNION NUT |

| 310/5. | [1] | 146614-2300 | JOINT CONNECTION |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 355. | [1] | 146934-6900 | BRACKET |

| 356. | [1] | 139006-4700 | BLEEDER SCREW |

| 357. | [2] | 146613-5620 | PLATE |

| 800S. | [1] | 146018-0420 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146685-0410 | POTENTCIOMETER |

| 906. | [1] | 146982-6500 | NAMEPLATE |

Include in #2:

104780-9016

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 504

9460613504

ZEXEL

104780-9016

1047809016

NISSAN-DIESEL

167003S900

167003s900

Zexel num

Bosch num

Firm num

Name

104780-9016

9 460 613 504

167003S900 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD25-TI K 11CJ INJECTION PUMP ASSY VE4 VE

TD25-TI K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

Measure (solenoid timer with O-ring), S/T Off OFF

Measure (solenoid timer with O-ring), S/T Off OFF

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

44.5

44

45

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

37.3

36

38.6

Boost pressure

kgf/cm2

0.38

0.366

0.394

Boost pressure

mmHg

280

270

290

Average injection quantity

mm3/st.

54.8

54.3

55.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

66.6

66.1

67.1

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

44.5

43.5

45.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

800

800

800

Boost pressure

kPa

37.3

36

38.6

Boost pressure

kgf/cm2

0.38

0.366

0.394

Boost pressure

mmHg

280

270

290

Average injection quantity

mm3/st.

54.8

53.8

55.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

66.6

65.6

67.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

68.3

65.8

70.8

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

68.3

65.3

71.3

Oil temperature

degC

50

48

52

Injection timing adjustment_09

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

63.7

60.7

66.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

16.7

14.7

18.7

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2750

2750

2750

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

50.4

50.4

50.4

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

16.7

13.7

19.7

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.4

14.4

18.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.4

13.9

18.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

60

95

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

60

95

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Overflow quantity with S/T ON

cm3/min

450

320

580

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Pressure with S/T ON

kPa

510

471

549

Pressure with S/T ON

kgf/cm2

5.2

4.8

5.6

Pressure with S/T OFF

kPa

432

403

461

Pressure with S/T OFF

kgf/cm2

4.4

4.1

4.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

432

393

471

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_03

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

647

608

686

Pressure with S/T OFF

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

3.8

3.4

4.2

Timer stroke with S/T OFF

mm

2

1.8

2.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

0.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

3.8

3.3

4.3

Timer stroke with S/T OFF

mm

2

1.7

2.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

7.8

7.3

8.2

Timer stroke with S/T OFF

mm

6.9

6.3

7.5

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

47

46.5

47.5

Timer stroke TA

mm

1.7

1.7

1.7

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

47

46

48

Timer stroke TA

mm

1.7

1.7

1.7

Timer stroke variation dT

mm

0.3

0

0.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

kgf/cm2

0.82

0.806

0.834

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

35

32.5

37.5

Timer stroke TA

mm

1.1

1.1

1.1

Timer stroke variation dT

mm

0.9

0.5

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.7

0.6

0.8

BCS stroke

mm

4.5

4.3

4.7

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

33.5

28.5

38.5

Test data Ex:

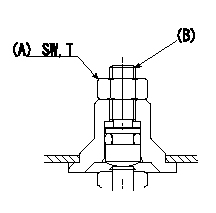

0000001601 BCS ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=800r/min N2=500r/min P1=37.3kPa(280mmHg) P2=0kPa(0mmHg) Q1=45.1+-1.0mm3/st T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=800r/min N2=500r/min P1=37.3kPa(280mmHg) P2=0kPa(0mmHg) Q1=45.1+-1.0mm3/st T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

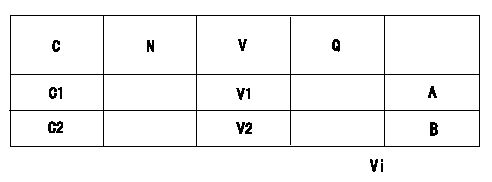

0000001801 POTENTIOMETER ADJUSTMENT

C:Position of the control lever

N:Pump speed (r/min)

V:Output voltage (V)

Q:Injection quantity (mm3/st)

A:Adjusting point

B:Checking point

C1:Idling

C2:Full speed

Vi:Applied voltage input

----------

V1=1.93+-0.03(V)

----------

V1=1.93+-0.03(V) V2=9.97++(V)

----------

V1=1.93+-0.03(V)

----------

V1=1.93+-0.03(V) V2=9.97++(V)

Information:

Cat ELC

Caterpillar provides Cat ELC (Extended Life Coolant) for use in the following applications:

Heavy-duty diesel engines

Automotive applicationsWhen Cat ELC is compared to conventional coolants, the Cat ELC anti-corrosion package is based on a different additive system. Cat ELC has been formulated with the correct amounts of additives. Superior corrosion protection is provided for all metals that are in engine cooling systems.Cat ELC extends the service life of the coolant to 12000 service hours or 6 years. Cat ELC does not require the frequent addition of the Cat ELC Extender additive. An Extender is the only additional maintenance that is needed at 6000 service hours or one half of the Cat ELC service life.Cat ELC is available in a 1:1 premixed cooling solution with distilled water. The premixed Cat ELC provides freeze protection to −37 °C (−34 °F). The premixed Cat ELC is recommended for the initial fill of the cooling system. The premixed Cat ELC is also recommended for topping off the cooling system.Cat ELC Concentrate is also available. Cat ELC Concentrate can be used to lower the freezing point to −52 °C (−62 °F) for arctic conditions.Containers of several sizes are available. Refer to this Special Publication, "Coolant Recommendations" article for available quantities and part numbers.Note: Cat ELC can be used in most diesel and gasoline OEM engines. Cat ELC meets

Caterpillar provides Cat ELC (Extended Life Coolant) for use in the following applications:

Heavy-duty diesel engines

Automotive applicationsWhen Cat ELC is compared to conventional coolants, the Cat ELC anti-corrosion package is based on a different additive system. Cat ELC has been formulated with the correct amounts of additives. Superior corrosion protection is provided for all metals that are in engine cooling systems.Cat ELC extends the service life of the coolant to 12000 service hours or 6 years. Cat ELC does not require the frequent addition of the Cat ELC Extender additive. An Extender is the only additional maintenance that is needed at 6000 service hours or one half of the Cat ELC service life.Cat ELC is available in a 1:1 premixed cooling solution with distilled water. The premixed Cat ELC provides freeze protection to −37 °C (−34 °F). The premixed Cat ELC is recommended for the initial fill of the cooling system. The premixed Cat ELC is also recommended for topping off the cooling system.Cat ELC Concentrate is also available. Cat ELC Concentrate can be used to lower the freezing point to −52 °C (−62 °F) for arctic conditions.Containers of several sizes are available. Refer to this Special Publication, "Coolant Recommendations" article for available quantities and part numbers.Note: Cat ELC can be used in most diesel and gasoline OEM engines. Cat ELC meets

Have questions with 104780-9016?

Group cross 104780-9016 ZEXEL

Nissan-Diesel

104780-9016

9 460 613 504

167003S900

INJECTION-PUMP ASSEMBLY

TD25-TI

TD25-TI