Information injection-pump assembly

ZEXEL

104769-2181

1047692181

NISSAN

1670022J01

1670022j01

Rating:

Cross reference number

ZEXEL

104769-2181

1047692181

NISSAN

1670022J01

1670022j01

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.7

31.3

32.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

39

38.6

39.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.7

30.7

32.7

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

39

38

40

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

43.9

41.9

45.9

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

42.8

40.3

45.3

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

42.5

39.5

45.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

35.8

34.8

36.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

35.8

32.8

38.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

27.4

22.4

32.4

Difference in delivery

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2700

2700

2700

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

3

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.6

6.6

8.6

Difference in delivery

mm3/st.

0.9

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.6

5.6

9.6

Difference in delivery

mm3/st.

1.4

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.8

7.8

17.8

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.4

8.4

8.4

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.2

9.7

22.7

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.4

8.4

8.4

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

38

38

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

38

38

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

45.6

48.2

Boost pressure

mmHg

352

342

362

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

45.6

48.2

Boost pressure

mmHg

352

342

362

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

46.6

47.2

Boost pressure

mmHg

352

342

362

Pressure

kPa

373

344

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

46.6

47.2

Boost pressure

mmHg

352

342

362

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

578.5

539

618

Pressure

kgf/cm2

5.9

5.5

6.3

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

706

667

745

Pressure

kgf/cm2

7.2

6.8

7.6

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

45.6

48.2

Boost pressure

mmHg

352

342

362

Timer stroke

mm

1.3

1.1

1.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.9

45.6

48.2

Boost pressure

mmHg

352

342

362

Timer stroke

mm

1.3

1

1.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

4.9

4.3

5.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

6.85

6.3

7.4

Oil temperature

degC

52

50

54

_05

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

6.95

6.5

7.4

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1.8

1.7

1.9

BCS stroke

mm

3.9

3.8

4

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

39

34

44

Test data Ex:

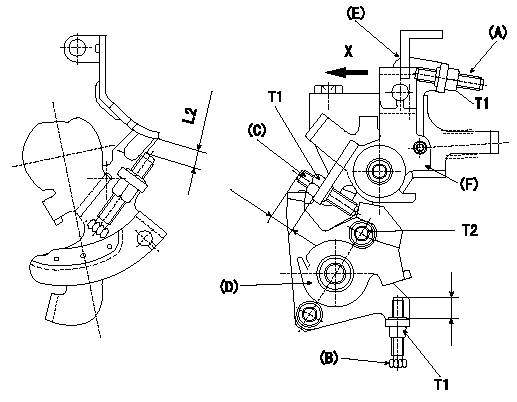

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

1. CSD adjustment

Turn the lever (D) clockwise and adjust screw (B) so that the timer piston advance angle is a (L1). Then fix using the nut.

2. With intermediate lever screw (C)'s fixing lever (D) positioned as in 1., pull the intermediate lever in direction X. After confirming that it contacts the stop position, adjust so that screw (C) contacts lever (D) and then fix using the nut.

(Intermediate lever status in 2.: full speed, indicates timer's a advance.

Confirm that the timer piston advances to b deg when the intermediate lever is returned.

3. Fast idle adjustment

Pull the intermediate lever in direction x to contact the stopper and adjust the screw (A) so that the gap between the idle set bracket and the idle screw is L2. Fix using the nut.

The gap between the control lever at the idle position and the screw (A) must be L3.

(E) control lever

(F) intermediate lever

----------

a=2deg b=0deg L1=1.6mm L2=6+-0.05mm L3=(1.7)mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) L2=6+-0.05mm

----------

a=2deg b=0deg L1=1.6mm L2=6+-0.05mm L3=(1.7)mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) L2=6+-0.05mm

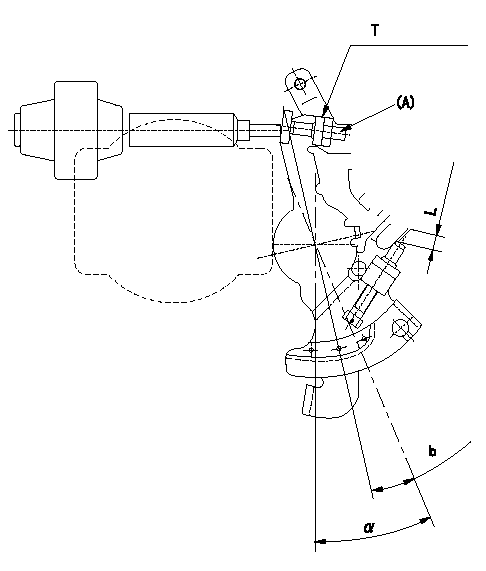

0000001901 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L (thickness gauge) between the idle set bracket and the idle screw.

2. In the above condition, adjust so that the dashpot adjusting screw (A) contacts the pushrod. Then, fix using the nut.

Record the dashpot return time t.

a = alpha

----------

L=3.8+-0.05mm t=1.8+-0.5sec

----------

T=5~7N-m(0.5~0.7kgf-m) b=7.4deg L=3.8+-0.05mm

----------

L=3.8+-0.05mm t=1.8+-0.5sec

----------

T=5~7N-m(0.5~0.7kgf-m) b=7.4deg L=3.8+-0.05mm

Information:

Typical Example2. Remove eight bolts (3) that fasten pipe (1) to the elbow. Remove four bolts (2) that fasten the elbow to the aftercooler cover. Remove elbow (4).

Typical Example3. Remove bracket (5) from the oil filter tube and the oil level gauge group.

Typical Example4. Remove four bolts (7) from the air inlet elbow. Remove plate (6) and elbow (8). 5. Remove two tubes (10) from the air compressor to the aftercooler.6. Remove elbows (9) from the aftercooler housing.

Typical Example

Put identification on bolts (12) because they are 6.4 mm (.25 in) longer than all other bolts. They must be installed in the same location.

7. Remove bolts (11) and (12) from cover, and remove the cover.

Put identification on bolt (14) because it is 12.7 mm (.50 in) shorter than all the other bolts. It must be installed in the same location. Remove four adapters (15). Put plugs in both holes in the aftercooler core assembly. This will keep coolant out of the engine intake manifold.

8. Remove bolts (13) and (14) that hold the core assembly in position.9. Remove the aftercooler core assembly. 10. Remove air line (17) from the fuel ratio control valve.11. Remove eight bolts (16). Remove housing assembly (18).Install Aftercooler

1. Check all seals and gaskets for damage. If damaged, use new parts for replacement.

All foreign material and dirt must be removed from the gasket surface and inside the housing and intake manifold.

2. Install housing (1) and air line (2) to the fuel control valve. 3. Install four new seals (3) on the core assembly. Put clean glycerin on the O-ring seals. 4. Install core assembly (4) inside the housing. Remove plugs in both holes of the aftercooler core assembly. Install the bolts that fasten the core to housing. Install the bolts in their original location. 5. Put clean engine oil in the bores of the adapters. Install adapters (5). 6. Put cover (6) in position on the aftercooler. Install the two bolts in position (7). These bolts are 6.4 mm (.25 in) longer than all other bolts around the housing. Install the remainder of the bolts around the housing. 7. Install elbows (8). 8. Install two tubes (9) between the air compressor and the aftercooler.

Typical Example9. Install elbow (10) and plate (11) on the aftercooler cover. Install the bracket that is a support for the oil filter tube and the oil level gauge group. Install the oil filter tube and the oil level gauge group.

Typical Example10. Install eight bolts (13) that fasten the pipe to elbow (14). Install the elbow in the turbocharger.11. Install the four bolts that fasten the elbow to aftercooler cover (12).12. Fill the engine with coolant to the correct level. See the Operation & Maintenance Manual.