Information injection-pump assembly

ZEXEL

104769-2112

1047692112

Rating:

Cross reference number

ZEXEL

104769-2112

1047692112

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31.3

30.9

31.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.5

29.5

33.5

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31.3

30.3

32.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

30.7

28.7

32.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

28.6

26.6

30.6

Oil temperature

degC

52

50

54

Injection timing adjustment_06

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.3

24.3

28.3

Oil temperature

degC

55

52

58

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

19

17

21

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

19

15.5

22.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

6.5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7

6

8

Difference in delivery

mm3/st.

1.1

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7

5

9

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

8

3

13

Oil temperature

degC

50

48

52

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

42

38

46

Difference in delivery

mm3/st.

15

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

373

344

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

588.5

549

628

Pressure

kgf/cm2

6

5.6

6.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

735.5

696

775

Pressure

kgf/cm2

7.5

7.1

7.9

Oil temperature

degC

55

52

58

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.3

1.1

1.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.3

1

1.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3.1

2.7

3.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.55

8.1

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

44

39

49

Test data Ex:

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust the adjusting bolt (A) so that the starting injection quantity is within the standard and fix using the locknut (B).

(C) Stop lever

----------

----------

----------

----------

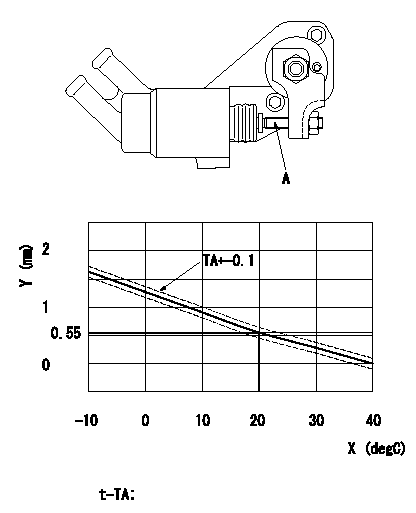

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke determined from the graph below using the screw.

Caution: The temperature of the wax at adjustment must not exceed a.

A = screw

Y = timer stroke TA

X = temperature t

----------

a=30degC

----------

t-TA;-10<=t(degC)<=20 TA=-0.0367t+1.284 20<=t(degC)<=40 TA=-0.0275t+1.1

----------

a=30degC

----------

t-TA;-10<=t(degC)<=20 TA=-0.0367t+1.284 20<=t(degC)<=40 TA=-0.0275t+1.1

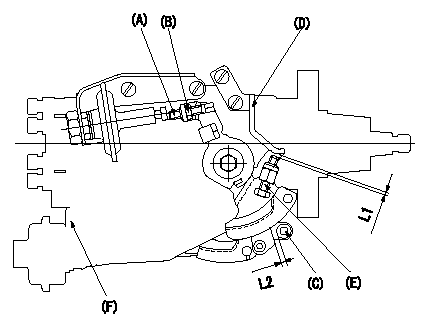

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw and the bracket.

2. In the above condition, adjust the elongated hole so that the pushrod contacts the control lever. Then, fix using the bolt.

TT

Note:

(1)The dashpot and control lever contact faces must be smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix the actuator bracket (A) so that the clearance between the control lever and the ISC lever's roller (B) is L2.

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm T=6~9N-m{0.6~0.9kgf-m}

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm T=6~9N-m{0.6~0.9kgf-m}

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm

Information:

Start By:a. remove oil pump1. Check the connecting rods and caps for their identification and location. 2. Turn the crankshaft until the connecting rod caps are in position.3. Remove two bolts (1) and the cap from the connecting rod. Remove the lower half of the bearing from the cap.4. Push the connecting rod away from the crankshaft. Remove the upper half of the bearing from the connecting rod. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install the upper half of the bearing in the connecting rod.6. Pull the connecting rod slowly on to the crankshaft.7. Install the lower half of the bearing in the cap. Be sure the tabs in the back of bearings are in the tab grooves of the connecting rod and cap.The serviceman must be very careful to use Plastigage, Tool (A) correctly. The following points must be remembered:Make sure that the backs of the bearings and the bores are clean and dry.Make sure that the bearing locking tabs are properly seated in their slots.The crankshaft must be free of oil where the Plastigage touches it.Put a piece of Plastigage (A) on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.Do not turn the crankshaft with the Plastigage installed.Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.Remove the Plastigage before reinstalling the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in) the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the other.For complete details concerning measuring bearing clearance, see the topic, "Engine Bearings & Crankshafts", SEBD0531. 8. Use Plastigage (A) to check the bearing clearance.9. Put Plastigage (A) on the bearing.10. Put 2P2506 Thread Lubricant on the threads of the rod bolts and seat surfaces of the nuts. Be sure the cylinder numbers on the rod cap and rod are the same and are on the same side of connecting rod. Numbers are on the same side of the rod and cap as are the bearing tab slots. If new rods are installed, put the cylinder number on the rod and cap. Do not turn the crankshaft when Plastigage (A) is in position.