Information injection-pump assembly

ZEXEL

104769-2111

1047692111

Rating:

Cross reference number

ZEXEL

104769-2111

1047692111

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31.4

30.9

31.9

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

18.5

15

22

Injection timing adjustment_03

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

29.1

27.1

31.1

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31.4

30.4

32.4

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.1

29.1

33.1

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

18.5

15.5

21.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.8

8.8

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.3

9.3

Difference in delivery

mm3/st.

1.4

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

4

Boost compensator adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

7.5

2.5

12.5

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

44.8

40.8

48.8

Basic

*

Remarks

Refer to additional devices.

Refer to additional devices.

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

588.5

549

628

Pressure

kgf/cm2

6

5.6

6.4

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

735.5

696

775

Pressure

kgf/cm2

7.5

7.1

7.9

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.3

1.1

1.5

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.3

1

1.6

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3.1

2.7

3.5

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.55

8.1

9

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

44

39

49

Control lever angle gamma

From idle deg. 11 10.5 11.5

From idle deg. 11 10.5 11.5

Test data Ex:

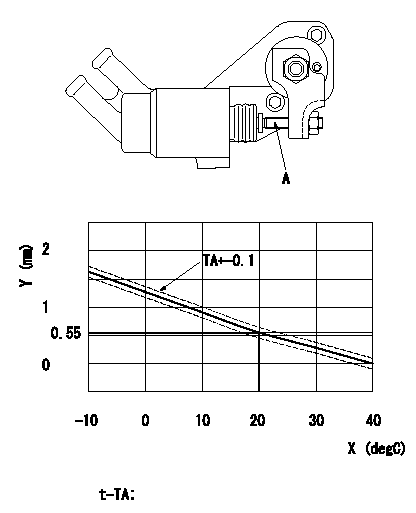

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke determined from the graph below using the screw.

Caution: The temperature of the wax at adjustment must not exceed a.

A = screw

Y = timer stroke TA

X = temperature t

----------

a=30degC

----------

t-TA;-10<=t(degC)<=20 TA=-0.0367t+1.284 20<=t(degC)<=40 TA=-0.0275t+1.1

----------

a=30degC

----------

t-TA;-10<=t(degC)<=20 TA=-0.0367t+1.284 20<=t(degC)<=40 TA=-0.0275t+1.1

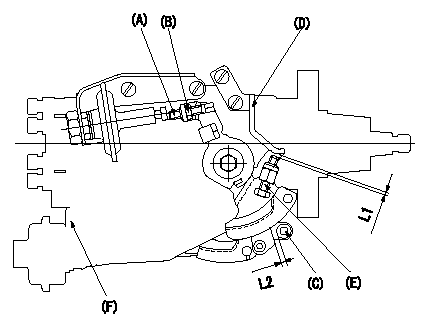

0000001901 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L1 (thickness gauge) between the idle set screw and the bracket.

2. In the above condition, adjust the elongated hole so that the pushrod contacts the control lever. Then, fix using the bolt.

TT

Note:

(1)The dashpot and control lever contact faces must be smooth.

(2)Confirm that the control lever returns to the idling position.

ISC actuator installation

1. Maintain the control lever in the idling position.

2. Fix the actuator bracket (A) so that the clearance between the control lever and the ISC lever's roller (B) is L2.

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm T=6~9N-m{0.6~0.9kgf-m}

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm T=6~9N-m{0.6~0.9kgf-m}

----------

L1=3.8+-0.05mm L2=1.5+-0.5mm

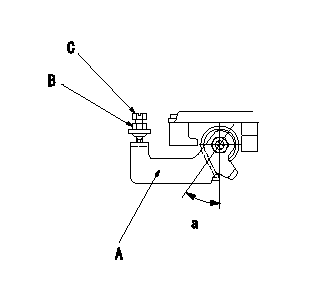

0000002001 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Fix the stop lever's starting injection quantity adjusting bolt. At adjustment, adjust the bolt so that the starting injection quantity is as specified and then fix using the locknut.

A = stop lever

B = locknut

C = adjusting bolt

----------

----------

a=32+-4deg

----------

----------

a=32+-4deg

Information:

Start By:a. remove timing gear coverb. remove fuel injection pump housing and governor 1. Remove four bolts (2), plate (3) and idler gear (1). 2. If the camshaft is not going to be removed, use Tool (A) to remove camshaft gear (4).

Do not turn the crankshaft with the camshaft gear removed. Damage can be caused to the pistons and valves or both.

3. Remove bolts (5) that hold timing gear plate (6) to the cylinder block.4. Remove timing gear plate (6). 5. Use Tool (B) to remove the bearing from the idler gear. The following steps are for the installation of the timing gears and plate.6. Install a new gasket on the timing gear plate.7. Put timing gear plate (6) in position on the cylinder block and install the bolts that hold the timing gear plate to the cylinder block.8. Heat camshaft gear (4) to a maximum temperature of 205° C (400° F) for no longer than three hours and install it on the camshaft.9. Use Tool (B) and install the bearing in the idler gear. Set the gear on the front face (face with the timing marks). Drive the bearing from the rear face toward the front face of the gear. Install the bearing to a depth of 1.5 0.5 mm (.06 .02 in) below the rear face of the idler gear.10. Install the idler gear, plate and bolts. Be sure No. 1 cylinder is at top center on the compression stroke. Install the idler gear so "V" mark (7) on the idler gear is in alignment with the "V" mark on the crankshaft gear. "K" marks (8) on the camshaft gear can be seen at the outer edges of the idler gear.End By:a. install fuel injection pump housing and governorb. install timing gear cover

Do not turn the crankshaft with the camshaft gear removed. Damage can be caused to the pistons and valves or both.

3. Remove bolts (5) that hold timing gear plate (6) to the cylinder block.4. Remove timing gear plate (6). 5. Use Tool (B) to remove the bearing from the idler gear. The following steps are for the installation of the timing gears and plate.6. Install a new gasket on the timing gear plate.7. Put timing gear plate (6) in position on the cylinder block and install the bolts that hold the timing gear plate to the cylinder block.8. Heat camshaft gear (4) to a maximum temperature of 205° C (400° F) for no longer than three hours and install it on the camshaft.9. Use Tool (B) and install the bearing in the idler gear. Set the gear on the front face (face with the timing marks). Drive the bearing from the rear face toward the front face of the gear. Install the bearing to a depth of 1.5 0.5 mm (.06 .02 in) below the rear face of the idler gear.10. Install the idler gear, plate and bolts. Be sure No. 1 cylinder is at top center on the compression stroke. Install the idler gear so "V" mark (7) on the idler gear is in alignment with the "V" mark on the crankshaft gear. "K" marks (8) on the camshaft gear can be seen at the outer edges of the idler gear.End By:a. install fuel injection pump housing and governorb. install timing gear cover