Information injection-pump assembly

ZEXEL

104769-2022

1047692022

Rating:

Cross reference number

ZEXEL

104769-2022

1047692022

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

29.5

29

30

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

18.5

15

22

Injection timing adjustment_03

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

30.45

28.1

32.8

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

29.5

28.5

30.5

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.8

26.6

31

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

18.5

15.5

21.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.8

6.3

9.3

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.8

5.8

9.8

Difference in delivery

mm3/st.

2.5

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

4

Boost compensator adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

9.5

4.5

14.5

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

44.8

40.8

48.8

Basic

*

Remarks

Refer to additional devices.

Refer to additional devices.

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

450

318

582

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

588.5

549

628

Pressure

kgf/cm2

6

5.6

6.4

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

735.5

696

775

Pressure

kgf/cm2

7.5

7.1

7.9

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

2

2.6

Basic

*

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

1.9

2.7

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

4.2

3.6

4.8

_04

Pump speed

r/min

2500

2500

2500

Timer stroke

mm

8.55

8.1

9

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

9

8

10

Timer stroke variation dT

mm

0.5

0.2

0.8

Basic

*

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

44

39

49

Control lever angle gamma

Partial lever position deg. 11 10.5 11.5

Partial lever position deg. 11 10.5 11.5

Test data Ex:

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust adjusting bolt so that the starting injection quantity is within the standard.

Fix using nut.

----------

----------

----------

----------

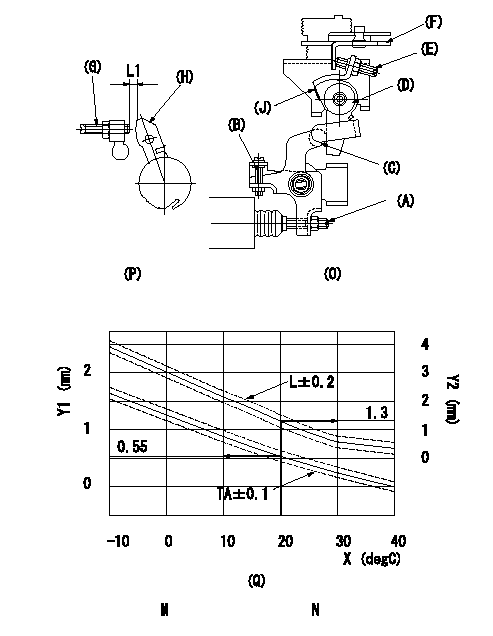

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Timer advance adjustment (refer to Fig 1 [O], 3 [Q]).

(1)Determine the timer advance angle from the graph in Fig. 3 (Q).

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

2. Setting the intermediate lever position (refer to fig 1 and fig 2)

(1)Insert a block gauge L1 between the idle set screw (G) and the lever (H).

(2)When the intermediate lever (D) is perpendicular, fix it so that it contacts the control lever (F).

(3)Align lever (D) perpendicular to the aligning mark (J).

3. W-CSD lever adjustment [refer to fig 1 (O) and fig 2 (P)]

(1)Insert a block gauge L2 determined from the graph (L-t) in the figure 3 (Q) between the idling set screw (G) and the lever (H).

(2)Adjust screw (B) so that the W-CSD lever (C)'s roller contacts the intermediate lever (D) and fix using the nut.

The temperature of the wax at adjustment must not exceed a.

Note:

When inserting the block gauge, separate lever (C) and (D) using screw (B) to prevent excessive force on the lever.

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever L dimension (mm)

M:Graph TA-t:

-10 <= t (deg C) <= 20: TA = -0.0367t + 1.284

20 <= t (deg C) <= 40: TA = -0.0275t + 1.1

N:Graph L-t

-10<= t (deg C) <= 20: L = -0.0867t + 3.03

20 <= t (deg C) <= 60: L = -0.075 t + 2.8

30 <= t (deg C) <= 40: L = -0.02t + 1.15

----------

L1=1.3+-0.05mm L2=L1+-0.05mm a=30degC

----------

L1=1.3+-0.05mm

----------

L1=1.3+-0.05mm L2=L1+-0.05mm a=30degC

----------

L1=1.3+-0.05mm

Information:

P-102: Engine Cranks But Will Not Start

Probable root causes:* Electrical power supply to the ECM.* Electrical connections to the fuel injectors.* Fuel supply* Engine Speed/Timing Signal* ECM or Personality Module failure.* Combustion problemPerform the following tests in order:1. P-210: Electrical Power Supply Test.2. If ECAP/DDT does not communicate with ECM, refer to P-120: ECAP/DDT Will Not Communicate With 3176 System, in this manual.3. Check that Fuel Injector Connector (J5/P5) is installed and oriented correctly.4. Check Fuel Pressure. Also, check that fuel system is primed and that fuel supply and return lines are not restricted. In temperatures below 0° C (32° F), check for congealed fuel (wax).5. P-221: Engine Speed/Timing Signal Test. Also be sure the timing reference ring is installed correctly (if the ring was installed backward during reassembly, the engine will not start).6. Check for combustion problems (too cold or mechanical problem).P-103: Engine Misfires, Runs Rough Or Is Unstable

If the problem is intermittent and cannot be re-created, refer to P-111: Intermittent Low Power Or Power Cutouts.If the problem is consistent and can be re-created, continue with this procedure. Probable root causes: If the problem only occurs under certain conditions (high rpm, full load, etc.) test the engine under those conditions. Troubleshooting the symptoms under other conditions can give misleading results.* Three cylinder cutout* Individual cylinder malfunction* Throttle position signal* Fuel supply - high pressure- low pressure- air in fuel- poor quality fuel* Air inlet restriction* Exhaust restrictionPerform the following tests in order:1. Verify that the complaint is not about the normal operation of the three-cylinder cutout feature.2. Isolate misfiring cylinder(s). Refer to P-222: Isolating Misfiring Cylinders, in this manual.3. Check throttle linkage adjustment. Refer to P-303: Throttle Position Sensor Adjustment, in this manual.4. Check Throttle Position Sensor. Refer to P-211: Throttle Position Sensor Test, in this manual.5. Check fuel quality. Refer to the Truck Performance Diagnostic Guide, Form No. SEBD0808.6. Inspect fuel system and check fuel pressure. Refer to 3176 Vehicular Diesel Engine, Form No. SENR4964, for Systems Operation, Testing & Adjusting.7. Check for air in fuel.8. Check for restrictions in the air inlet and exhaust systems. Refer to 3176 Vehicular Diesel Engine, Form No. SENR4964, for Systems Operation, Testing & Adjusting.P-104: Low Power/Poor Or No Response To Throttle

Probable root causes:* Active diagnostic codes* Customer Specified Parameters (normal operation)* Throttle position signal* Boost pressure signal* Fuel supply* Air inlet or exhaust restrictions* Inlet air system leaksPerform the following tests in order:1. Troubleshoot any ACTIVE diagnostic codes. * Codes 25 or 42 limit power or rpm or both* Code 32 limits engine speed to low idle* Code 56 may limit engine speed to low idle, depending on which parameter caused the code to be generated2. Verify that complaint is not normal (programmed parameter) operation.3. Verify that engine has shifted out of Cold Mode4. P-211: Throttle Position Sensor Test4. P-225: Boost Pressure Sensor Test5. Inspect fuel system components and check for correct fuel pressure.6. Check the air inlet and exhaust systems for restrictions.P-110: Intermittent Engine Shutdowns

Use this procedure ONLY

Probable root causes:* Electrical power supply to the ECM.* Electrical connections to the fuel injectors.* Fuel supply* Engine Speed/Timing Signal* ECM or Personality Module failure.* Combustion problemPerform the following tests in order:1. P-210: Electrical Power Supply Test.2. If ECAP/DDT does not communicate with ECM, refer to P-120: ECAP/DDT Will Not Communicate With 3176 System, in this manual.3. Check that Fuel Injector Connector (J5/P5) is installed and oriented correctly.4. Check Fuel Pressure. Also, check that fuel system is primed and that fuel supply and return lines are not restricted. In temperatures below 0° C (32° F), check for congealed fuel (wax).5. P-221: Engine Speed/Timing Signal Test. Also be sure the timing reference ring is installed correctly (if the ring was installed backward during reassembly, the engine will not start).6. Check for combustion problems (too cold or mechanical problem).P-103: Engine Misfires, Runs Rough Or Is Unstable

If the problem is intermittent and cannot be re-created, refer to P-111: Intermittent Low Power Or Power Cutouts.If the problem is consistent and can be re-created, continue with this procedure. Probable root causes: If the problem only occurs under certain conditions (high rpm, full load, etc.) test the engine under those conditions. Troubleshooting the symptoms under other conditions can give misleading results.* Three cylinder cutout* Individual cylinder malfunction* Throttle position signal* Fuel supply - high pressure- low pressure- air in fuel- poor quality fuel* Air inlet restriction* Exhaust restrictionPerform the following tests in order:1. Verify that the complaint is not about the normal operation of the three-cylinder cutout feature.2. Isolate misfiring cylinder(s). Refer to P-222: Isolating Misfiring Cylinders, in this manual.3. Check throttle linkage adjustment. Refer to P-303: Throttle Position Sensor Adjustment, in this manual.4. Check Throttle Position Sensor. Refer to P-211: Throttle Position Sensor Test, in this manual.5. Check fuel quality. Refer to the Truck Performance Diagnostic Guide, Form No. SEBD0808.6. Inspect fuel system and check fuel pressure. Refer to 3176 Vehicular Diesel Engine, Form No. SENR4964, for Systems Operation, Testing & Adjusting.7. Check for air in fuel.8. Check for restrictions in the air inlet and exhaust systems. Refer to 3176 Vehicular Diesel Engine, Form No. SENR4964, for Systems Operation, Testing & Adjusting.P-104: Low Power/Poor Or No Response To Throttle

Probable root causes:* Active diagnostic codes* Customer Specified Parameters (normal operation)* Throttle position signal* Boost pressure signal* Fuel supply* Air inlet or exhaust restrictions* Inlet air system leaksPerform the following tests in order:1. Troubleshoot any ACTIVE diagnostic codes. * Codes 25 or 42 limit power or rpm or both* Code 32 limits engine speed to low idle* Code 56 may limit engine speed to low idle, depending on which parameter caused the code to be generated2. Verify that complaint is not normal (programmed parameter) operation.3. Verify that engine has shifted out of Cold Mode4. P-211: Throttle Position Sensor Test4. P-225: Boost Pressure Sensor Test5. Inspect fuel system components and check for correct fuel pressure.6. Check the air inlet and exhaust systems for restrictions.P-110: Intermittent Engine Shutdowns

Use this procedure ONLY