Information injection-pump assembly

BOSCH

9 460 614 859

9460614859

ZEXEL

104762-4120

1047624120

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104762-4120 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104662-4120 |

| 3. | NUMBER PLATE | 146984-4200 |

| 4. | _ | |

| 5. | CAPSULE | 146620-0120 |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105158-5130 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 22.0{224} |

| 10. | NOZZLE-HOLDER | 105088-2002 |

| 11. | NOZZLE | 105017-9400 |

Scheme ###:

| 1/6. | [1] | 146601-1100 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-1820 | DRIVE SHAFT |

| 12/1. | [1] | 146200-1800 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-8920 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0301 | SLOTTED WASHER |

| 29. | [1] | 146221-1820 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-0100 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146306-3100 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146406-0820 | HYDRAULIC HEAD |

| 50. | [1] | 146406-0820 | HYDRAULIC HEAD |

| 50. | [1] | 146406-0820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [6] | 146433-0100 | GASKET |

| 55. | [6] | 146430-7020 | DELIVERY-VALVE ASSEMBLY VE70 |

| 56. | [6] | 146432-0200 | COMPRESSION SPRING |

| 58. | [6] | 146440-0720 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146822-1420 | GOVERNOR COVER |

| 67/1. | [1] | 146806-8520 | GOVERNOR COVER |

| 67/2. | [1] | 146515-2520 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146530-0000 | CONTROL LEVER |

| 67/5B. | [1] | 146530-0100 | CONTROL LEVER STAMP 001 |

| 67/5C. | [1] | 146832-1500 | CONTROL LEVER |

| 67/5D. | [1] | 146832-1600 | CONTROL LEVER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146587-4500 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-1300 | CONTROL LEVER |

| 67/12B. | [1] | 146540-1400 | CONTROL LEVER MARK:0 |

| 67/12C. | [1] | 146540-5200 | CONTROL LEVER |

| 67/12D. | [1] | 146540-5300 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/18. | [1] | 146587-2000 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/23. | [1] | 146925-2520 | BRACKET |

| 67/24. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/25. | [1] | 013020-6040 | UNION NUT |

| 67/26. | [1] | 146925-2920 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-4600 | THREADED PIN L=24MM |

| 67/201B. | [1] | 146545-4700 | THREADED PIN L=26MM |

| 67/201C. | [1] | 146545-4800 | THREADED PIN L=28MM |

| 67/202. | [1] | 146598-5000 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 67/204. | [1] | 146545-4500 | DAMPER |

| 95. | [1] | 146871-9820 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146976-0700 | SLIDING SLEEVE |

| 116. | [1] | 146576-0400 | CAP |

| 117/1. | [1] | 146877-0820 | PLUG L=5.0 |

| 117/1. | [1] | 146877-0920 | PLUG L=5.1 |

| 117/1. | [1] | 146877-1020 | PLUG L=5.2 |

| 117/1. | [1] | 146877-1120 | PLUG L=5.3 |

| 117/1. | [1] | 146877-1220 | PLUG L=5.4 |

| 117/1. | [1] | 146877-1320 | PLUG L=5.5 |

| 117/1. | [1] | 146877-1420 | PLUG L=5.6 |

| 117/1. | [1] | 146877-1520 | PLUG L=5.7 |

| 117/1. | [1] | 146877-1620 | PLUG L=5.8 |

| 117/1. | [1] | 146877-1720 | PLUG L=5.9 |

| 117/1. | [1] | 146877-1820 | PLUG L=6.0 |

| 117/1. | [1] | 146877-1920 | PLUG L=6.1 |

| 117/1. | [1] | 146877-2020 | PLUG L=6.2 |

| 117/1. | [1] | 146877-2120 | PLUG L=6.3 |

| 117/1. | [1] | 146877-2220 | PLUG L=6.4 |

| 117/1. | [1] | 146877-2320 | PLUG L=6.5 |

| 117/1. | [1] | 146877-2420 | PLUG L=6.6 |

| 117/1. | [1] | 146877-2520 | PLUG L=6.7 |

| 117/1. | [1] | 146877-2620 | PLUG L=6.8 |

| 117/1. | [1] | 146877-2720 | PLUG L=6.9 |

| 117/1. | [1] | 146877-2820 | PLUG L=7.0 |

| 117/1. | [1] | 146877-2920 | PLUG L=7.1 |

| 117/1. | [1] | 146877-3020 | PLUG L=7.2 |

| 117/1. | [1] | 146877-3120 | PLUG L=7.3 |

| 117/1. | [1] | 146877-3220 | PLUG L=7.4 |

| 117/1. | [1] | 146877-3320 | PLUG L=7.5 |

| 117/1. | [1] | 146877-3420 | PLUG L=7.6 |

| 117/1. | [1] | 146877-3520 | PLUG L=7.7 |

| 117/1. | [1] | 146877-3620 | PLUG L=7.8 |

| 117/1. | [1] | 146877-3720 | PLUG L=7.9 |

| 117/1. | [1] | 146877-3820 | PLUG L=8.0 |

| 117/1. | [1] | 146877-3920 | PLUG L=8.1 |

| 117/1. | [1] | 146877-4020 | PLUG L=8.2 |

| 117/1. | [1] | 146877-4120 | PLUG L=8.3 |

| 117/1. | [1] | 146877-4220 | PLUG L=8.4 |

| 120. | [1] | 146879-2220 | RETAINING PIN |

| 122. | [1] | 146580-2900 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-1120 | CAPSULE |

| 130/2. | [1] | 139508-0200 | GASKET |

| 130/3. | [1] | 146422-0300 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-3320 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146688-3920 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 233. | [1] | 146658-8920 | WIRE |

| 240. | [1] | 146650-1320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-0120 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0700 | EYE BOLT |

| 247. | [1] | 146677-7520 | PIPE |

| 247. | [1] | 146677-7520 | PIPE |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 343. | [1] | 146598-8320 | CAP |

| 800S. | [1] | 146018-9020 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-1100 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 825S. | [1] | 146598-8120 | CAP |

| 835S. | [1] | 146598-7320 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 837S. | [1] | 146598-7310 | CAP |

| 903. | [1] | 146620-0120 | CAPSULE |

| 903/2. | [1] | 146600-1300 | O-RING |

| 906. | [1] | 146984-4200 | NAMEPLATE |

Include in #2:

104762-4120

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 614 859

9460614859

ZEXEL

104762-4120

1047624120

Zexel num

Bosch num

Firm num

Name

104762-4120

9 460 614 859

INJECTION-PUMP ASSEMBLY

K 11CK INJECTION PUMP ASSY VE6 VE

K 11CK INJECTION PUMP ASSY VE6 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77.8

77.3

78.3

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

62.7

58.2

67.2

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

70.9

66.9

74.9

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77.8

76.8

78.8

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

74.9

71.4

78.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

56.7

52.7

60.7

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

56.7

52.2

61.2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

7.3

11.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

6.8

11.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85.8

80.8

90.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85.8

80.8

90.8

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

750

620

880

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T OFF

kPa

500

471

529

Pressure with S/T OFF

kgf/cm2

5.1

4.8

5.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure with S/T OFF

kPa

500

451

549

Pressure with S/T OFF

kgf/cm2

5.1

4.6

5.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T OFF

mm

1.1

0.8

1.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

800

800

800

Timer stroke with S/T ON

mm

1.9

1.2

2.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T OFF

mm

1.1

0.7

1.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

1075

1075

1075

Timer stroke with S/T OFF

mm

1.9

1.4

2.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.77

5.67

5.87

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

33

28

38

Test data Ex:

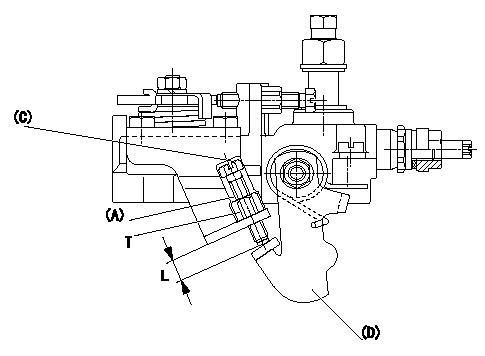

0000001801 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (B) protrusion: L

(C) = Cap

(D) = Stop lever

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

Information:

Solenoid Valve Replacement

Make reference to the at the beginning of the Testing And Adjusting section.

This procedure assumes that the ether cylinder mounted on the failed solenoid valve may still contain ether and is usable. If the ether cylinder is empty and needs replacement, complete this procedure and then follow the normal cylinder replacement procedure. See Ether Cylinder Replacement.

Solenoid Valve Assembly The solenoid valve itself is not serviceable. The complete solenoid valve assembly must be replaced. This includes the mounting bracket.1. Turn the disconnect switch to the OFF position. 2. Remove the ether cylinder from failed solenoid valve (1).3. Disconnect ether line (2) from the outlet of failed solenoid valve (1).4. Disconnect (unplug) solenoid valve harness connector (3). 5. Remove the reset switch bracket from the solenoid valve by removing two bolts (4). Leave the reset switch and wires intact on the bracket.6. Remove the solenoid valve assembly, which includes the mounting bracket, from the vehicle by removing two bolts (5).

Orifice Fitting And Filter7. Prepare the new solenoid valve for installation by installing a new orifice fitting and filter.

The orifice fitting has left-hand threads.

8. Attach the new solenoid valve and reset switch bracket to the vehicle. Tighten top two bolts (5) and leave lower two bolts (4) loose.

Gasket Filter9. Install a new gasket filter into the inlet of the solenoid valve.10. Install the same ether cylinder. See within Ether Cylinder Replacement. Hand tighten the ether cylinder to the solenoid valve. 11. Adjust the reset switch bracket such that reset switch button (6) depresses as much as possible while contacting the ether cylinder. Tighten lower two bolts (4) which fasten the reset switch bracket and solenoid valve to the vehicle. The reset switch must be adjusted correctly in order for the ether injection system to operate properly. The function of the reset switch is: to be OPEN (depressed switch button) when an ether cylinder is installed, and to be CLOSED (extended switch button) when the ether cylinder is removed. Ether injection is disabled when an ether cylinder is removed (reset switch closed).12. Verify that the reset switch is OPEN by continuity checking between the pin and socket in harness plug (7) of the reset switch. There should be no continuity.13. Reconnect the harnesses to the solenoid valve and the reset switch. Turn the disconnect switch to the ON position.Ether Cylinder Removal

Non-Empty Cylinders

During maintenance or servicing, the ether cylinders may need to be removed when they are not empty (for example, the cylinders may have to be removed to gain access to some other item requiring service). Under these conditions, it is desirable to remove and reinstall the ether cylinders without disturbing the "ether cylinder timers" within the ether injection control. This procedure allows the same ether cylinder to be reinstalled after it has been removed. Normal ether cylinder replacement is performed when the ether cylinder is empty. Normal removal of an empty ether cylinder resets the "ether cylinder timers" within the ether injection control. See Ether Cylinder Replacement. Failure to

Make reference to the at the beginning of the Testing And Adjusting section.

This procedure assumes that the ether cylinder mounted on the failed solenoid valve may still contain ether and is usable. If the ether cylinder is empty and needs replacement, complete this procedure and then follow the normal cylinder replacement procedure. See Ether Cylinder Replacement.

Solenoid Valve Assembly The solenoid valve itself is not serviceable. The complete solenoid valve assembly must be replaced. This includes the mounting bracket.1. Turn the disconnect switch to the OFF position. 2. Remove the ether cylinder from failed solenoid valve (1).3. Disconnect ether line (2) from the outlet of failed solenoid valve (1).4. Disconnect (unplug) solenoid valve harness connector (3). 5. Remove the reset switch bracket from the solenoid valve by removing two bolts (4). Leave the reset switch and wires intact on the bracket.6. Remove the solenoid valve assembly, which includes the mounting bracket, from the vehicle by removing two bolts (5).

Orifice Fitting And Filter7. Prepare the new solenoid valve for installation by installing a new orifice fitting and filter.

The orifice fitting has left-hand threads.

8. Attach the new solenoid valve and reset switch bracket to the vehicle. Tighten top two bolts (5) and leave lower two bolts (4) loose.

Gasket Filter9. Install a new gasket filter into the inlet of the solenoid valve.10. Install the same ether cylinder. See within Ether Cylinder Replacement. Hand tighten the ether cylinder to the solenoid valve. 11. Adjust the reset switch bracket such that reset switch button (6) depresses as much as possible while contacting the ether cylinder. Tighten lower two bolts (4) which fasten the reset switch bracket and solenoid valve to the vehicle. The reset switch must be adjusted correctly in order for the ether injection system to operate properly. The function of the reset switch is: to be OPEN (depressed switch button) when an ether cylinder is installed, and to be CLOSED (extended switch button) when the ether cylinder is removed. Ether injection is disabled when an ether cylinder is removed (reset switch closed).12. Verify that the reset switch is OPEN by continuity checking between the pin and socket in harness plug (7) of the reset switch. There should be no continuity.13. Reconnect the harnesses to the solenoid valve and the reset switch. Turn the disconnect switch to the ON position.Ether Cylinder Removal

Non-Empty Cylinders

During maintenance or servicing, the ether cylinders may need to be removed when they are not empty (for example, the cylinders may have to be removed to gain access to some other item requiring service). Under these conditions, it is desirable to remove and reinstall the ether cylinders without disturbing the "ether cylinder timers" within the ether injection control. This procedure allows the same ether cylinder to be reinstalled after it has been removed. Normal ether cylinder replacement is performed when the ether cylinder is empty. Normal removal of an empty ether cylinder resets the "ether cylinder timers" within the ether injection control. See Ether Cylinder Replacement. Failure to

Have questions with 104762-4120?

Group cross 104762-4120 ZEXEL

Komatsu

104762-4120

9 460 614 859

INJECTION-PUMP ASSEMBLY