Information injection-pump assembly

BOSCH

9 460 614 769

9460614769

ZEXEL

104762-4090

1047624090

Rating:

Cross reference number

BOSCH

9 460 614 769

9460614769

ZEXEL

104762-4090

1047624090

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77

76.5

77.5

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

65.4

60.9

69.9

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

70.2

66.2

74.2

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77

76

78

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

73.4

69.9

76.9

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

56.7

52.7

60.7

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

56.7

52.2

61.2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

7.3

11.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

6.8

11.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85.8

80.8

90.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85.8

80.8

90.8

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

800

670

930

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

598

559

637

Pressure

kgf/cm2

6.1

5.7

6.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

598

549

647

Pressure

kgf/cm2

6.1

5.6

6.6

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.8

1.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.1

0.7

1.5

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1075

1075

1075

Timer stroke

mm

1.7

1.2

2.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.77

5.67

5.87

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

33

28

38

Test data Ex:

0000001801 STARTING I/Q ADJUSTMENT

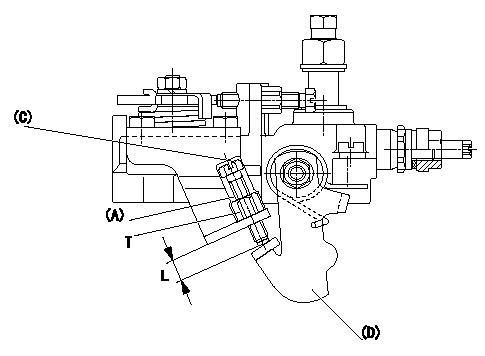

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (B) protrusion: L

(C) = Cap

(D) = Stop lever

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

Information:

(1) Diameter of rocker shaft ... 19.012 to 19.037 mm (.7485 to .7495 in.) Overall length ... 661.1938 mm (26.03125 in.)(2) Inside diameter of rocker arm ... 22.23 to 22.255 mm (.875 go .8762 in.)(3) Outside diameter of bushing ... 22.28 to 22.314 mm (.877 to .8785 in.) Interference fit of bushing in rocker lever ... 0.020 to 0.089 mm (.0008 to .0035 in.)Inside diameter of bushing (after it's reamed) ... 19.063 to 19.101 mm (.7505 to .7520 in.)Clearance of rocker shaft in bushing ... 0.03 to 0.089 mm (.001 to .0035 in.)Maximum permissible clearance ... 0.13 mm (.005 in.) See Rocker Shaft Assembly in TESTING AND ADJUSTING for proper alignment of the oil holes in the bushing and rocker lever.(4) Torque for bolts and nuts that hold rocker shaft assembly to cylinder head (tighten bolts from center outward) ... 75 N m (55 lb.ft.)(5) Install seal in cylinder head before rocker shaft assembly is installed.(6) Overall length of push rod ... 265.58 to 267.72 mm (10.456 to 10.540 in.) Shank diameter ... 7.87 to 7.92 mm (.310 to .312 in.)(7) Tappets (valve lifters): Overall length ... 75.4063 mm (2.96875 in.)Shank outside diameter ... 18.987 to 19.012 mm (.7475 to .7485 in.)Cylinder block tappet bore diameter ... 19.05 to 19.0818 mm (.750 to .75125 in.)Running clearance between tappet and block ... 0.038 to 0.0953 mm (.0015 to .00375 in.)Outside diameter of tappet foot ... 30.163 mm (1.1875 in.) (8) Diameter of camshaft journals: No. 1 journal ... 50.71 to 50.737 mm (1.9965 to 1.9975 in.)Minimum permissible diameter ... 50.660 mm (1.9945 in.)No. 2 journal ... 50.457 to 50.483 mm (1.9865 to 1.9875 in.)Minimum permissible diameter ... 50.406 mm (1.9845 in.)No. 3 journal ... 50.203 to 50.229 mm (1.9765 to 1.9775 in.)Minimum permissible diameter ... 50.152 mm (1.9745 in.)No. 4 journal ... 49.949 to 49.975 mm (1.9665 to 1.9675 in.)Minimum permissible diameter ... 48.898 mm (1.9645 in.)(See topic Cylinder Block for camshaft bore specifications.) (10) Height of the lobes of the camshaft. To get height use the procedure that follows:A. Measure base circle (11).B. Add lobe lift (9) to base circle measurement. Total is camshaft lobe height. Camshaft lobe lift (9) is:Intake ... 7.704 to 7.780 mm (.3033 to .3063 in.)Exhaust ... 7.805 to 7.881 mm (.3073 to .3103 in.)Minimum permissible height of lobes is 0.25 mm (.010 in.) less than measurement in Step B.(12) Torque for camshaft bolt ... 70 N m (50 lb.ft.)(13) End play of camshaft ... 0.10 to 0.41 mm (.004 to .016 in.) Maximum permissible end play ... 0.53 mm (.021 in.)(14) Camshaft thrust washer: Outside diameter ... 72.95 to 73.00 mm (2.872 to 2.874 in.)Cylinder block recess diameter for thrust washer ... 73.03 to 73.28 mm (2.875 to 2.885 in.)Clearance of washer in recess ... 0.03 to 0.33 mm (.001 to .013 in.)Inside diameter ... 44.45 mm (1.750 in.)Thickness ... 5.49 to 5.54 mm (.216 to .218 in.)Cylinder block