Information injection-pump assembly

ZEXEL

104761-4380

1047614380

Rating:

Cross reference number

ZEXEL

104761-4380

1047614380

Zexel num

Bosch num

Firm num

Name

104761-4380

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Checker parts number

407980-228*

ECU part number

407913-1342

Wire harness

407980-2300

Intermediate harness

157992-8900

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

50.2

49.7

50.7

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

56.4

55.9

56.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

62

61.5

62.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

50.2

49.2

51.2

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

700

700

700

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

56.4

55.4

57.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

62

61

63

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

58.7

57.7

59.7

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

56.7

52.7

60.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

22.8

20.8

24.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

22.8

20.3

25.3

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

6.6

4.6

8.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

6.6

4.1

9.1

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

650

650

650

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

0

0

0

Average injection quantity

mm3/st.

66.5

51.5

81.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

TCV duty (%) F TCV 60Hz

%

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Overflow quantity

cm3/min

600

468

732

Basic

50+-2

Stop lever angle

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Pressure

kPa

579

550

608

Pressure

kgf/cm2

5.9

5.6

6.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Pressure

kPa

294

294

Pressure

kgf/cm2

3

3

Oil temperature

degC

48

46

50

Stop lever angle_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Pressure

kPa

579

540

618

Pressure

kgf/cm2

5.9

5.5

6.3

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Pressure

kPa

667

618

716

Pressure

kgf/cm2

6.8

6.3

7.3

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

70

70

70

Timer stroke

mm

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

5.6

3.6

7.6

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

7

5

9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

70

70

70

Timer stroke

mm

3.5

3.1

3.9

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

0

0

0

Timer stroke

mm

0

0

0

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

mmHg

400

390

410

TCV duty (%) F TCV 60Hz

%

100

100

100

Timer stroke

mm

6.95

6.5

7.4

Oil temperature

degC

50

48

52

0000001301

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000002701

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.76

6.66

6.86

MS dimension

mm

1.3

1.2

1.4

BCS stroke

mm

2.9

2.7

3.1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

43

38

48

Test data Ex:

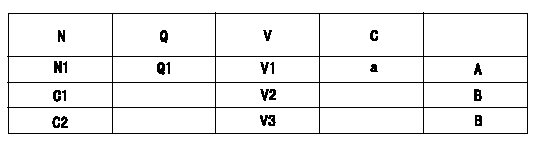

0000001901 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1kPa {P2 mmHg}

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 (V) at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

At TCV duty 100%

A:Adjusting point

B:Performance standards

C:Control lever angle

N:Pump speed

V:Output voltage

Q:Injection quantity

C1:Idle

C2:Full speed

----------

V1=6.00+-0.03V P1=0kPa P2=0mmHg Vi=10V

----------

N1=1240r/min Q1=40.6+-1.0cm3/1,000st V1=6.00+-0.03V V2=1.04+-0.69V V3=8.18+-0.61V a=-deg

----------

V1=6.00+-0.03V P1=0kPa P2=0mmHg Vi=10V

----------

N1=1240r/min Q1=40.6+-1.0cm3/1,000st V1=6.00+-0.03V V2=1.04+-0.69V V3=8.18+-0.61V a=-deg

Information:

(1) Thickness of spacer plate ... 9.970 0.025 mm (.3925 .0010 in) Thickness of spacer plate gasket ... 0.208 0.025 mm (.0082 .0010 in) For height of liner over top of spacer plate make reference to Cylinder Liner Projection.(2) Camshaft bearing bore (installed) ... 58.80 0.06 mm (2.315 .002 in) Bore in block for camshaft bearings ... 65.100 0.025 mm (2.5630 .0010 in)(3) Bore in block for main bearings (standard size) ... 96.926 0.013 mm (3.8160 .0005 in) Bore in block for main bearings 0.51 mm (.020 in) oversize ... 97.436 0.013 mm (3.8361 .0005 in)(4) Dimension from center of main bearing bore to top of cylinder block (new) ... 383.515 0.165 mm (15.099 .0064 in)(5) Dimension from center of main bearing bore to bottom of cylinder block (new) ... 153.99 0.10 mm (6.063 .004 in)(6) Torque for bolts holding bearing caps for main bearings: a. Put 2P2506 Thread Lubricant on threads and washer face.b. Tighten all bolts to ... 41 4 N m (30 3 lb ft)c. Put a mark on each bolt and cap.d. Tighten all bolts from mark ... 90 5° Install bearing caps with the part number toward the front of the engine. Be sure that the mark (number) on the bearing cap next to the bolt hole is in agreement with the mark in the cylinder block.(7) Clearance between main bearing cap and cylinder block ... 0.033 mm (.0013 in) tight to 0.043 mm (.0017 in) loose Main bearing cap width ... 165.095 0.020 mm (6.4998 .0008 in)Width of cylinder block for main bearing cap ... 165.100 0.018 mm (6.5000 .0007 in) (8) Piston cooling orifice.

There are holes in the bores for the main bearings, between the cylinders for piston cooling orifices. These holes must have orifices (8) installed.

(9) Distance two dowels extend from the surface of the cylinder block ... 19.8 0.5 mm (.78 .02 in)(10) Distance hollow dowel extends from the surface of the cylinder block ... 16.0 0.5 mm (.63 .02 in)(11) Depth to install two dowels below the surface of the cylinder block (apply loctite #11358) ... 1.0 0.5 mm (.04 .02 in)(12) Distance dowels extend from the front face of the cylinder block ... 22.4 0.5 mm (.88 .02 in)(13) Distance stud extends from the front face of the cylinder block ... 15.7 0.5 mm (.62 .02 in)(14) Distance two dowels extend from the rear face of the cylinder block ... 12.7 0.5 mm (.50 .02 in)

There are holes in the bores for the main bearings, between the cylinders for piston cooling orifices. These holes must have orifices (8) installed.

(9) Distance two dowels extend from the surface of the cylinder block ... 19.8 0.5 mm (.78 .02 in)(10) Distance hollow dowel extends from the surface of the cylinder block ... 16.0 0.5 mm (.63 .02 in)(11) Depth to install two dowels below the surface of the cylinder block (apply loctite #11358) ... 1.0 0.5 mm (.04 .02 in)(12) Distance dowels extend from the front face of the cylinder block ... 22.4 0.5 mm (.88 .02 in)(13) Distance stud extends from the front face of the cylinder block ... 15.7 0.5 mm (.62 .02 in)(14) Distance two dowels extend from the rear face of the cylinder block ... 12.7 0.5 mm (.50 .02 in)

Have questions with 104761-4380?

Group cross 104761-4380 ZEXEL

Nissan-Diesel

Nissan-Diesel

104761-4380

INJECTION-PUMP ASSEMBLY