Information injection-pump assembly

BOSCH

9 460 614 763

9460614763

ZEXEL

104761-4330

1047614330

NISSAN-DIESEL

16700WJ103

16700wj103

Rating:

Cross reference number

BOSCH

9 460 614 763

9460614763

ZEXEL

104761-4330

1047614330

NISSAN-DIESEL

16700WJ103

16700wj103

Zexel num

Bosch num

Firm num

Name

104761-4330

9 460 614 763

16700WJ103 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD42T K

TD42T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

48.1

47.6

48.6

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

26.7

25.4

28

Boost pressure

kgf/cm2

0.27

0.256

0.284

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

57.3

56.8

57.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

59.7

59.2

60.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

48.1

47.1

49.1

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

700

700

700

Boost pressure

kPa

26.7

25.4

28

Boost pressure

kgf/cm2

0.27

0.256

0.284

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

57.3

56.3

58.3

Basic

*

Oil temperature

degC

48

46

50

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

59.7

58.7

60.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

61.4

58.4

64.4

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

56

52

60

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

17.8

15.8

19.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

17.8

15.3

20.3

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.2

5.2

9.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.2

4.7

9.7

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

61.5

51.5

81.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

61.5

51.5

81.5

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure

kPa

441

412

470

Pressure

kgf/cm2

4.5

4.2

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure

kPa

441

402

480

Pressure

kgf/cm2

4.5

4.1

4.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure

kPa

588

549

627

Pressure

kgf/cm2

6

5.6

6.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke

mm

3.1

2.9

3.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke

mm

2

1.5

2.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke

mm

3.1

2.8

3.4

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke

mm

5.3

4.8

5.8

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke

mm

7

6.5

7.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

46

45.5

46.5

Timer stroke TA

mm

2.4

2.2

2.6

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

46

45

47

Timer stroke TA

mm

2.4

2.2

2.6

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

35

32.5

37.5

Timer stroke TA

mm

1.6

1.1

2.1

Timer stroke variation dT

mm

1.5

1.5

1.5

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.76

6.66

6.86

MS dimension

mm

1.3

1.2

1.4

BCS stroke

mm

2.9

2.7

3.1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

40

35

45

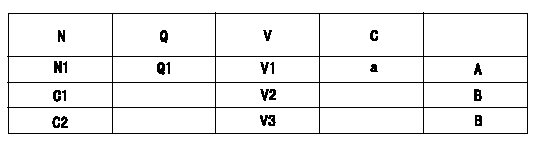

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1kPa {P2 mmHg}

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 (V) at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

N:Pump speed

Q:Injection quantity

V:Output voltage

A:Performance standards

B:ON, OFF switch standard

C:Angle of the control lever

D:OFF-->ON

E:OFF-->ON

F:Adjusting point

C1:Idle

C2:Full-speed

----------

V1=5.04+-0.03V P1=53.3kPa P2=400mmHg Vi=10V

----------

N1=1080r/min Q1=48.9+-1.0cm3/1,000st V1=5.04+-0.03V V2=0.81+-0.6V V3=7.25+-0.75V a=-deg

----------

V1=5.04+-0.03V P1=53.3kPa P2=400mmHg Vi=10V

----------

N1=1080r/min Q1=48.9+-1.0cm3/1,000st V1=5.04+-0.03V V2=0.81+-0.6V V3=7.25+-0.75V a=-deg

Information:

Ultra Low Sulfur Diesel (ULSD) poses a greater static ignition hazard than earlier diesel formulations, with a higher sulfur content, which may result in a fire or explosion. Consult with your fuel or fuel system supplier for details on proper grounding and bonding practices.

Note: The removal of sulfur and other compounds in Ultra Low Sulfur Diesel (ULSD) fuel decreases the conductivity of ULSD and increases the ability of the fuel to store static charge. Refineries may have treated the fuel with a static dissipating additive. However, there are many factors that can reduce the effectiveness of the additive over time. Static charges can build up in ULSD fuel while the fuel is flowing through fuel delivery systems. Static electricity discharge when combustible vapors are present could result in a fire or explosion. Therefore, ensuring that the entire system used to refuel your machine (fuel supply tank, transfer pump, transfer hose, nozzle, and others) is properly grounded and bonded is important. Consult with your fuel or fuel system supplier to ensure that the delivery system is in compliance with fueling standards for proper grounding and bonding practices.The two basic types of distillate diesel fuel are No. 2 diesel fuel and No. 1 diesel fuel. No. 2 diesel fuel is the most commonly available summer grade diesel fuel. No. 1 diesel fuel is a winter grade diesel fuel. During the winter months fuel suppliers will typically blend No. 1 and No. 2 diesel fuel in various percentages to meet the historical low ambient temperature cold-flow needs for a given area or region. No. 2 diesel fuel is a heavier diesel fuel than No. 1 diesel fuel. In cold weather, heavier fuels can cause problems with fuel filters, fuel lines, fuel tanks, and fuel storage. Heavier diesel fuels such as No. 2 diesel fuel can be used in diesel engines that operate in cold temperatures with an appropriate amount of a well proven pour point depressant additive. For more information on fuels which include blends of No. 1 and No. 2 diesel fuel, consult your fuel supplier.When you use No. 2 diesel fuel or other heavier fuels, some of the fuel characteristics may interfere with successful cold-weather operation. Additional information about the characteristics of diesel fuel is available. This information contains a discussion on the modification to the characteristics of diesel fuel. There are several possible methods that can be used to compensate for the fuel qualities that may interfere with cold-weather operation. These methods include the use of starting aids, engine coolant heaters, fuel heaters, and de-icers. In addition, the manufacturer of the fuel can add cold flow improvers and/or blend No. 1 and No. 2 diesel in various percentages.Not all areas of the world classify diesel fuel using the No. 1 and No. 2 nomenclature described above. But, the basic principles of using additives and/or blending fuels of different densities to help compensate for the fuel qualities that may interfere with cold-weather operation are the same.Starting Aids

The use of

Have questions with 104761-4330?

Group cross 104761-4330 ZEXEL

Nissan-Diesel

104761-4330

9 460 614 763

16700WJ103

INJECTION-PUMP ASSEMBLY

TD42T

TD42T