Information injection-pump assembly

BOSCH

9 460 612 007

9460612007

ZEXEL

104761-4200

1047614200

NISSAN-DIESEL

167000Y705

167000y705

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104761-4200 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104661-4200 |

| 3. | NUMBER PLATE | 146959-3500 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1121 |

| 8. | Nozzle and Holder | 16600-43G03 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1130 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2720 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146221-1520 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6120 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2700 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2600 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-1600 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 42. | [1] | 146602-8500 | PLAIN WASHER |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [1] | 146234-0120 | GUIDE PIN |

| 50. | [1] | 146405-3320 | HYDRAULIC HEAD |

| 50. | [1] | 146405-3320 | HYDRAULIC HEAD |

| 50. | [1] | 146405-3320 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [6] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [6] | 146430-4420 | DELIVERY-VALVE ASSEMBLY |

| 56. | [6] | 146432-0000 | COMPRESSION SPRING |

| 58. | [6] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146760-1220 | MANIFOLD-PRESSURE COMP. |

| 67/1. | [1] | 146805-3720 | GOVERNOR COVER |

| 67/2. | [1] | 146515-2520 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146536-7020 | CONTROL LEVER |

| 67/5B. | [1] | 146536-7120 | CONTROL LEVER |

| 67/6. | [1] | 014110-6440 | LOCKING WASHER |

| 67/7. | [1] | 146621-0700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/18. | [1] | 146592-5000 | COILED SPRING |

| 67/19. | [1] | 146541-3000 | BUSHING |

| 67/21. | [1] | 146592-5100 | COILED SPRING |

| 67/22. | [1] | 146541-3100 | SLOTTED WASHER |

| 67/31. | [1] | 146710-0800 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-1700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-1400 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-4100 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0000 | PLATE |

| 67/43. | [1] | 146715-0000 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-1400 | COILED SPRING |

| 67/48/1. | [1] | 146720-0000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-0100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-0200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-0300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-0400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-0500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-0600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-0700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-0800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-0900 | SPACER BUSHING L2.7 |

| 67/48/1. | [1] | 146720-1000 | SPACER BUSHING L2.9 |

| 67/48/1. | [1] | 146720-1100 | SPACER BUSHING L3.1 |

| 67/48/1. | [1] | 146720-1200 | SPACER BUSHING L3.3 |

| 67/48/1. | [1] | 146720-1300 | SPACER BUSHING L3.5 |

| 67/48/1. | [1] | 146720-1400 | SPACER BUSHING L2.8 |

| 67/48/1. | [1] | 146720-1500 | SPACER BUSHING L3.0 |

| 67/48/1. | [1] | 146720-1600 | SPACER BUSHING L3.2 |

| 67/48/1. | [1] | 146720-1700 | SPACER BUSHING L3.4 |

| 67/48/1. | [1] | 146720-1800 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146720-1900 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146720-2000 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146720-2100 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146720-2200 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146720-2300 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146720-2400 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146720-2500 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146720-2600 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146720-2700 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146720-2800 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-2900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146720-4500 | SPACER BUSHING L1.8 |

| 67/48/1. | [1] | 146720-4600 | SPACER BUSHING L1.9 |

| 67/48/1. | [1] | 146720-4700 | SPACER BUSHING L2.0 |

| 67/48/1. | [1] | 146720-4800 | SPACER BUSHING L2.1 |

| 67/48/1. | [1] | 146720-4900 | SPACER BUSHING L2.2 |

| 67/48/1. | [1] | 146720-5000 | SPACER BUSHING L2.3 |

| 67/48/1. | [1] | 146720-5100 | SPACER BUSHING L2.4 |

| 67/48/1. | [1] | 146720-5200 | SPACER BUSHING L2.5 |

| 67/48/1. | [1] | 146720-5300 | SPACER BUSHING L2.6 |

| 67/48/1. | [1] | 146725-2500 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146725-2600 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-2700 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146725-2800 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-2900 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146725-3000 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-3100 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146725-3200 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-3300 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146725-3400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-3500 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146725-3600 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-3700 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146725-3800 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-3900 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146725-4000 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-4100 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146725-4200 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-4300 | SPACER BUSHING L7.5 |

| 67/49. | [1] | 146721-4020 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/55. | [2] | 146620-6100 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146927-2300 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/99. | [2] | 010006-0870 | BLEEDER SCREW M6P1L8 7T |

| 67/100. | [1] | 146931-8620 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146861-6120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-8000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 120. | [1] | 146879-0720 | RETAINING PIN |

| 122. | [1] | 146580-1000 | GOVERNOR SPRING |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0620 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-7420 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 016520-1210 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 224. | [1] | 146928-7500 | BRACKET |

| 230. | [1] | 146932-4220 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-6420 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 020118-1440 | BLEEDER SCREW |

| 245. | [2] | 026512-1840 | GASKET D17.9&12.2T1.50 |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146665-1220 | PIPE |

| 251. | [1] | 014010-8140 | PLAIN WASHER D18&8.5T1.6 |

| 309. | [1] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146673-7521 | POTENTCIOMETER |

| 310/2. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/3. | [1] | 146620-1500 | FLAT-HEAD SCREW |

| 310/4. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 310/5. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/6. | [1] | 146661-0401 | BOOT |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146018-0420 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146683-8910 | POTENTCIOMETER |

| 906. | [1] | 146959-3500 | NAMEPLATE |

Include in #2:

104761-4200

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 007

9460612007

ZEXEL

104761-4200

1047614200

NISSAN-DIESEL

167000Y705

167000y705

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

51.3

50.8

51.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

kgf/cm2

0.16

0.146

0.174

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

57.4

56.9

57.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

56.7

56.2

57.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

51.3

50.3

52.3

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

700

700

700

Boost pressure

kPa

16

14.7

17.3

Boost pressure

kgf/cm2

0.16

0.146

0.174

Boost pressure

mmHg

120

110

130

Average injection quantity

mm3/st.

57.4

56.4

58.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

51.5

51.5

51.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

56.7

55.7

57.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

59

59

59

Oil temperature

degC

50

48

52

Injection timing adjustment_09

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

56.5

56.5

56.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

24

22

26

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

24

21.5

26.5

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.7

4.7

8.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6.7

4.2

9.2

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

61.5

51.5

81.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

61.5

51.5

81.5

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Overflow quantity with S/T ON

cm3/min

520

390

650

Oil temperature

degC

50

48

52

Remarks

Without S/T O-ring; S/T ON.

Without S/T O-ring; S/T ON.

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure with S/T ON

kPa

451

412

490

Pressure with S/T ON

kgf/cm2

4.6

4.2

5

Pressure with S/T OFF

kPa

343

314

372

Pressure with S/T OFF

kgf/cm2

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

343

304

382

Pressure with S/T OFF

kgf/cm2

3.5

3.1

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Pressure with S/T OFF

kPa

569

530

608

Pressure with S/T OFF

kgf/cm2

5.8

5.4

6.2

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.7

4.3

5.1

Timer stroke with S/T OFF

mm

2.5

2.3

2.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

0.9

0.4

1.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke with S/T ON

mm

4.7

4.2

5.2

Timer stroke with S/T OFF

mm

2.5

2.2

2.8

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Timer stroke with S/T OFF

mm

7

6.5

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37.5

38.5

Timer stroke TA

mm

1.6

1.4

1.8

Timer stroke variation dT

mm

0.9

0.9

0.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

38

37

39

Timer stroke TA

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

30

27.5

32.5

Timer stroke TA

mm

0.7

0.3

1.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.92

6.82

7.02

MS dimension

mm

1.5

1.4

1.6

BCS stroke

mm

1.5

1.3

1.7

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

10

6

14

Control lever angle beta

deg.

40

35

45

Test data Ex:

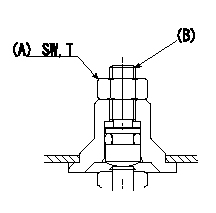

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=700r/min N2=500r/min P1=16.0kPa(120mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

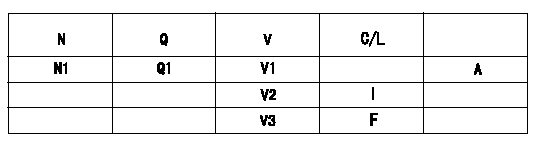

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

N:Pump speed

Q:Injection quantity

V:Output voltage

C/L: control lever position

F:Full-speed

I:Idle

A:Adjusting point

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.04+-0.03V

----------

N1=700r/min Q1=22.9+-1.0mm3/st V1=3.04+-0.03V V2=(1.72V) V3=(8.53V)

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.04+-0.03V

----------

N1=700r/min Q1=22.9+-1.0mm3/st V1=3.04+-0.03V V2=(1.72V) V3=(8.53V)

Information:

Cylinder Head And Valve Components

Check cylinder head for cracks before reconditioning.Flatness of the cylinder head should be within .006 in. (0.15 mm) total, and a maximum of .003 in. (0.08 mm) for any 6 in. (152.4 mm) span. A maximum stock removal of .010 in. (0.25 mm) is permissible when resurfacing the head.Always check the thickness of a cylinder head before resurfacing. The cylinder head may have been resurfaced before and would not have enough stock to be resurfaced again.To check the thickness of a cylinder head, measure through the fuel injection nozzle holes at each end of the cylinder head. For the correct thickness of the cylinder head, see the topic CYLINDER HEAD in the SPECIFICATIONS.The exhaust valve seats have replaceable inserts. To remove, use the 8S7170 Valve Seat Insert Puller Group.

REMOVING EXHAUST VALVE SEAT INSERTFreeze the exhaust valve seat inserts or use the 8S7170 Valve Seat Insert Puller Group to install inserts into head. Be sure bores are clean, free of burrs, and the insert has a good press fit into the bore.After inserts are installed, grind the seat face of the insert to be sure it is flat, has the correct angle, and is in alignment with the bore in the valve guide. For specifications, see VALVE GRINDING SPECIFICATIONS CHART. Replace exhaust valve seat inserts when valve seat width or valve head-to-cylinder head face can not be machined to the correct specification. For specifications, see VALVE GRINDING SPECIFICATIONS CHART.A 2N8943 Valve Seat Insert for the intake valve is available. This insert can be used in the repair of cylinder heads which have an intake valve seat with damage. Before, damage to an intake valve seat made replacement of the cylinder head assembly necessary.To use a 2N8943 Valve Seat Insert, the inlet port of the cylinder head must be machined to a diameter of 2.1470 .0005 in. (54.534 0.013 mm) and to a depth of .442 .002 in. (11.23 0.05 mm).To install a 2N8943 Valve Seat Insert into the cylinder head, freeze the insert or use a 2P2343 Extractor with the 8S7170 Valve Seat Insert Puller Group. After an insert is installed, grind the seat face of the insert to be sure it is flat, has the correct angle, and is in alignment with the bore in the valve guide. For specifications, see VALVE GRINDING SPECIFICATIONS CHART.Clean valve guides of all carbon and oil, using the 5P5176 Brush and a solvent.The valve guides are cast in the cylinder heads. Check each valve guide bore size 3/4 in. (19.1 mm) deep from each end. The bore size is .3745 .0005 in. (9.512 0.013 mm) and the maximum size worn is .3760 in. (9.550 mm). Valve guides worn more than the maximum wear size, can be restored to original tolerances through knurling.Use the 5P3536 Valve Guide Gauge Group to check the bore of the valve guides. Special Instructions GMG02562 gives complete and detailed instructions for use of the 5P3536 Valve Guide Gauge

Check cylinder head for cracks before reconditioning.Flatness of the cylinder head should be within .006 in. (0.15 mm) total, and a maximum of .003 in. (0.08 mm) for any 6 in. (152.4 mm) span. A maximum stock removal of .010 in. (0.25 mm) is permissible when resurfacing the head.Always check the thickness of a cylinder head before resurfacing. The cylinder head may have been resurfaced before and would not have enough stock to be resurfaced again.To check the thickness of a cylinder head, measure through the fuel injection nozzle holes at each end of the cylinder head. For the correct thickness of the cylinder head, see the topic CYLINDER HEAD in the SPECIFICATIONS.The exhaust valve seats have replaceable inserts. To remove, use the 8S7170 Valve Seat Insert Puller Group.

REMOVING EXHAUST VALVE SEAT INSERTFreeze the exhaust valve seat inserts or use the 8S7170 Valve Seat Insert Puller Group to install inserts into head. Be sure bores are clean, free of burrs, and the insert has a good press fit into the bore.After inserts are installed, grind the seat face of the insert to be sure it is flat, has the correct angle, and is in alignment with the bore in the valve guide. For specifications, see VALVE GRINDING SPECIFICATIONS CHART. Replace exhaust valve seat inserts when valve seat width or valve head-to-cylinder head face can not be machined to the correct specification. For specifications, see VALVE GRINDING SPECIFICATIONS CHART.A 2N8943 Valve Seat Insert for the intake valve is available. This insert can be used in the repair of cylinder heads which have an intake valve seat with damage. Before, damage to an intake valve seat made replacement of the cylinder head assembly necessary.To use a 2N8943 Valve Seat Insert, the inlet port of the cylinder head must be machined to a diameter of 2.1470 .0005 in. (54.534 0.013 mm) and to a depth of .442 .002 in. (11.23 0.05 mm).To install a 2N8943 Valve Seat Insert into the cylinder head, freeze the insert or use a 2P2343 Extractor with the 8S7170 Valve Seat Insert Puller Group. After an insert is installed, grind the seat face of the insert to be sure it is flat, has the correct angle, and is in alignment with the bore in the valve guide. For specifications, see VALVE GRINDING SPECIFICATIONS CHART.Clean valve guides of all carbon and oil, using the 5P5176 Brush and a solvent.The valve guides are cast in the cylinder heads. Check each valve guide bore size 3/4 in. (19.1 mm) deep from each end. The bore size is .3745 .0005 in. (9.512 0.013 mm) and the maximum size worn is .3760 in. (9.550 mm). Valve guides worn more than the maximum wear size, can be restored to original tolerances through knurling.Use the 5P3536 Valve Guide Gauge Group to check the bore of the valve guides. Special Instructions GMG02562 gives complete and detailed instructions for use of the 5P3536 Valve Guide Gauge