Information injection-pump assembly

BOSCH

F 01G 09W 0EY

f01g09w0ey

ZEXEL

104761-3040

1047613040

MITSUBISHI-HEAV

32B6500120

32b6500120

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104761-3040 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2720 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146221-1920 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-9120 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-5100 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146405-4420 | HYDRAULIC HEAD |

| 50. | [1] | 146405-4420 | HYDRAULIC HEAD |

| 50. | [1] | 146405-4420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [6] | 146433-0100 | GASKET |

| 55. | [6] | 146430-2020 | DELIVERY-VALVE ASSEMBLY VE20 |

| 56. | [6] | 146432-0000 | COMPRESSION SPRING |

| 58. | [6] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146822-1220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-1022 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146832-5500 | CONTROL LEVER MARK:255 |

| 67/5B. | [1] | 146832-5600 | CONTROL LEVER MARK:256 |

| 67/5C. | [1] | 146832-9300 | CONTROL LEVER MARK:293 |

| 67/5D. | [1] | 146832-9400 | CONTROL LEVER MARK:294 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146587-4500 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-1300 | CONTROL LEVER |

| 67/12B. | [1] | 146540-1400 | CONTROL LEVER MARK:0 |

| 67/12C. | [1] | 146540-5200 | CONTROL LEVER |

| 67/12D. | [1] | 146540-5300 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-7300 | FLAT-HEAD SCREW |

| 67/18. | [1] | 146587-0400 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/23. | [1] | 146925-2520 | BRACKET |

| 67/24. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/25. | [1] | 013020-6040 | UNION NUT |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-4600 | THREADED PIN L=24MM |

| 67/201B. | [1] | 146545-4700 | THREADED PIN L=26MM |

| 67/201C. | [1] | 146545-4800 | THREADED PIN L=28MM |

| 67/202. | [1] | 146598-5000 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 67/204. | [1] | 146545-4500 | DAMPER |

| 95. | [1] | 146891-3320 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG L5.6 |

| 117/1. | [1] | 146877-4800 | PLUG L5.7 |

| 117/1. | [1] | 146877-4900 | PLUG L5.8 |

| 117/1. | [1] | 146877-5000 | PLUG L5.9 |

| 120. | [1] | 146879-3720 | RETAINING PIN |

| 122. | [1] | 146580-1400 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-3720 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0120 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 235. | [1] | 146936-3000 | BRACKET |

| 236. | [2] | 010206-2240 | HEX-SOCKET-HEAD CAP SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-1420 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 245. | [1] | 139512-0500 | GASKET |

| 247. | [1] | 146669-1720 | INLET UNION |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 343. | [1] | 146598-8700 | CAP NUT |

| 410. | [1] | 014020-6140 | PLAIN WASHER D11.5&6.5 |

| 411. | [1] | 146598-6300 | CAP NUT |

| 800S. | [1] | 146020-4020 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 825S. | [1] | 146598-8600 | CAP NUT |

| 835S. | [1] | 146598-7320 | CAP |

| 836S. | [1] | 146598-7920 | CAP |

| 837S. | [1] | 146598-7310 | CAP |

| 838S. | [1] | 146598-6710 | CAP |

| 906. | [1] | 146940-4100 | NAMEPLATE |

| 907. | [1] | 025803-1640 | WOODRUFF KEY |

| 908. | [1] | 013021-2140 | UNION NUT |

| 909. | [1] | 014111-2440 | LOCKING WASHER |

Include in #2:

104761-3040

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09W 0EY

f01g09w0ey

ZEXEL

104761-3040

1047613040

MITSUBISHI-HEAV

32B6500120

32b6500120

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

45

44.5

45.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

41.2

36.7

45.7

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

45

44

46

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

41

36

46

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1263

1263

1263

Average injection quantity

mm3/st.

13.5

11.5

15.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1263

1263

1263

Average injection quantity

mm3/st.

13.5

11

16

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

368

368

368

Average injection quantity

mm3/st.

9.3

7.3

11.3

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

368

368

368

Average injection quantity

mm3/st.

9.3

6.8

11.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50.9

45.9

55.9

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50.9

45.9

55.9

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

368

368

368

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

410

280

540

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

800

800

800

Pressure

kPa

451

402

500

Pressure

kgf/cm2

4.6

4.1

5.1

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

900

900

900

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1000

1000

1000

Pressure

kPa

490

441

539

Pressure

kgf/cm2

5

4.5

5.5

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

1150

1150

1150

Pressure

kPa

530

481

579

Pressure

kgf/cm2

5.4

4.9

5.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

0.5

0.3

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

0.5

0.1

0.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1150

1150

1150

Timer stroke

mm

1.2

0.7

1.6

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.76

6.66

6.86

MS dimension

mm

2.5

2.4

2.6

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

31

26

36

Test data Ex:

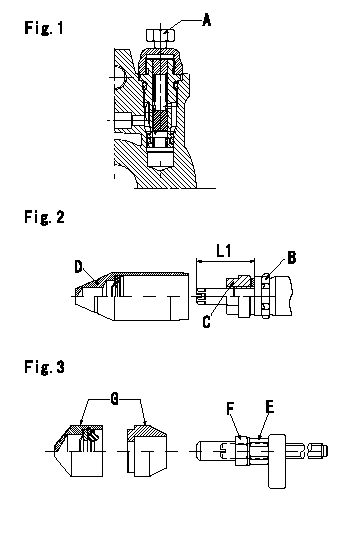

0000001801 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (A) protrusion: L

(B) Nut (SW10, T1 after completing adjustment)

(C) Cap

(D) Stop lever

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

0000001901 TAMPER PROOF

Tamperproof installation procedure

A:Position of break

B:Rubber vibration damper

C:Nut

D:Cap

E:Nut

F:Nut

G:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Target breaking torque T1

2) Maximum allowable breaking torque T2

3) Because the cap and the regulating valve are fixed using the MEC process, the bolt cannot be loosened after the bolt has been broken.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T3.

Fig. 3 Maximum speed adjusting screw

1) Tighten nut (E) to the torque T4.

2) To prevent nut (E) from turning together, fix (E) using the tool, then tighten nut (F) to torque T4.

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

Information:

Industrial Rating Definitions

The application examples are listed for reference only. Refer to the specific application information and guidelines within the Technical Marketing Information for exact rating determination.A Rating (Continuous)

* For heavy-duty service when engine is operated at rated load and speed up to 100 percent of the time without interruption or load cycling.* Time at full load up to 100 percent of the duty cycle.* Typical examples are: pipeline pumping, ventilation, and customer specifications.B Rating

* For servicing where power and/or speed are cyclic.* Time at full load not to exceed 80 percent of the duty cycle.* Typical examples are: irrigation where normal pump demand is 85 percent of the duty cycle, oil field mechanical pumping and drilling, and stationary/plant air compressors.C Rating (Intermittent)

* For service where power and/or speed are cyclic* The horsepower and speed capability of the engine can be used for one uninterrupted hour, followed by one hour of operation at or below the A rating.* Time at full load not to exceed 50 percent of the duty cycle.* Typical examples are: agricultural tractors, harvesters and combines, off-highway trucks, fire pump application power, blast hole drills, rock crushers and wood chippers with high torque rise, and oil field hoisting.D Rating

* For service when rated power is required for periodic overloads.* The maximum horsepower and speed capability of the engine can be used for a maximum of 30 uninterrupted minutes, followed by one hour of followed by one hour of C rating operation.* Time at full load not to exceed 10 percent of the duty cycle.* Typical examples are: offshore cranes, runway snow blowers, water well drills, portable air compressors, and fire pump certification power.E Rating

* For service where rated power is required for a short time for initial starting or sudden overload. For emergency service where standard power is unavailable.* The maximum horsepower and speed capability of the engine can be utilized for a maximum of 15 uninterrupted minutes, followed by one hour at C rating operation, or for the duration of the emergency.* Time at full load is not to exceed 5 percent of the duty cycle.* Typical examples are: standby centrifugal water pumps, oil field well servicing, crash trucks, and gas turbine starters.Rating Conditions

Unless otherwise specified, all ratings are based on SAE J1349 standard ambient conditions:* 100 kPa (29.6 inches of Hg) of pressure* 30 percent relative humidity, and* a temperature of 26°C (77°F).Ratings also apply at AS1501, BS5514, DIN6271, and ISO3046/1 standard conditions.Power for diesel engines is based on:* API gravity of 35 at 15°C (60°F),* fuel LHV of 42.780 kJ/g (18390 Btu/lb) at 29°C (84°F), and* fuel density of 838.9 g/L (7.0001 lb/US gal)Ratings are gross output ratings- the total output capability of the engine-equipped with standard accessories. Standard accessories include pumps for lubrication oil, fuel, and jacket water, and magneto as required. The gross output, minus the power required to drive auxiliary components, equals the net power available for the external (flywheel) load. Typical auxiliary components include cooling fans, air compressors,

The application examples are listed for reference only. Refer to the specific application information and guidelines within the Technical Marketing Information for exact rating determination.A Rating (Continuous)

* For heavy-duty service when engine is operated at rated load and speed up to 100 percent of the time without interruption or load cycling.* Time at full load up to 100 percent of the duty cycle.* Typical examples are: pipeline pumping, ventilation, and customer specifications.B Rating

* For servicing where power and/or speed are cyclic.* Time at full load not to exceed 80 percent of the duty cycle.* Typical examples are: irrigation where normal pump demand is 85 percent of the duty cycle, oil field mechanical pumping and drilling, and stationary/plant air compressors.C Rating (Intermittent)

* For service where power and/or speed are cyclic* The horsepower and speed capability of the engine can be used for one uninterrupted hour, followed by one hour of operation at or below the A rating.* Time at full load not to exceed 50 percent of the duty cycle.* Typical examples are: agricultural tractors, harvesters and combines, off-highway trucks, fire pump application power, blast hole drills, rock crushers and wood chippers with high torque rise, and oil field hoisting.D Rating

* For service when rated power is required for periodic overloads.* The maximum horsepower and speed capability of the engine can be used for a maximum of 30 uninterrupted minutes, followed by one hour of followed by one hour of C rating operation.* Time at full load not to exceed 10 percent of the duty cycle.* Typical examples are: offshore cranes, runway snow blowers, water well drills, portable air compressors, and fire pump certification power.E Rating

* For service where rated power is required for a short time for initial starting or sudden overload. For emergency service where standard power is unavailable.* The maximum horsepower and speed capability of the engine can be utilized for a maximum of 15 uninterrupted minutes, followed by one hour at C rating operation, or for the duration of the emergency.* Time at full load is not to exceed 5 percent of the duty cycle.* Typical examples are: standby centrifugal water pumps, oil field well servicing, crash trucks, and gas turbine starters.Rating Conditions

Unless otherwise specified, all ratings are based on SAE J1349 standard ambient conditions:* 100 kPa (29.6 inches of Hg) of pressure* 30 percent relative humidity, and* a temperature of 26°C (77°F).Ratings also apply at AS1501, BS5514, DIN6271, and ISO3046/1 standard conditions.Power for diesel engines is based on:* API gravity of 35 at 15°C (60°F),* fuel LHV of 42.780 kJ/g (18390 Btu/lb) at 29°C (84°F), and* fuel density of 838.9 g/L (7.0001 lb/US gal)Ratings are gross output ratings- the total output capability of the engine-equipped with standard accessories. Standard accessories include pumps for lubrication oil, fuel, and jacket water, and magneto as required. The gross output, minus the power required to drive auxiliary components, equals the net power available for the external (flywheel) load. Typical auxiliary components include cooling fans, air compressors,